7 chipper feed controller, 8 feed roller control bar – Echo 76824 Owners Manual v.2 User Manual

Page 20

PN 18280-00 R041306

18

OPERATION

4.7 chIppER fEED coNTRoLLER

The chipper is equipped with a pre-programmed feed controller.

The controller is located on the chipper housing above the chip-

per chute. The controller serves a variety of functions includ-

ing monitoring chipper disk RPM, controlling the feed roller, and

providing routine maintenance alerts. The control bar located on

the feed chute will control the feed roller.

The controller functions are further detailed below:

The controller operates the feed roller. The controller moni-

tors the RPMs of the chipper disk and won't operate until

the engine is at full RPM. If the chipper disk drops below

the normal operating RPM, the feed roller stops. When the

chipper disk returns to the normal operating RPM, the feed

roller will reengage.

The controller also has a “try again” feature. The controller

monitors the hydraulic pressure of the feed roller. If it senses

the level is too high (the feed roller becomes obstructed) the

controller will reverse the feed roller , removing the material

trying to be chipped. The controller will then engage the roller

into the forward position and try to feed the material again. If

this cycle continues, remove the obstruction manually. Trim

or reposition material if necessary.

1.

2.

The feed controller is programmed to display the following

text messages:

15 hour Service Code: "Change/Service blades".

100 hour Service Code: "Change engine oil".

Normal Operating RPM: "Feed control system

available".

high Pressure: "Try again feature activiated".

Feed Roller Stop Switch: "Forward feed stopped".

- Domestic Models: Disk RPM too low.

- S & F Models: Disk RPM too Low or Safety

Bar Activated.

SAFETY BAR: S & F models only. If safety bar has been

activated the red LED will light up. Push the reset/override

button to resume forward feed (Figure 4.3).

To overcome false trips of the safety bar by material

being chipped, the reset/override button may be held in for

5 seconds. To repeat, release button and hold in again.

NOTE: The RPM sensor on the disk must flash or the controller

won’t work. Clearance between the sensor and the bolt must be

between 1/32” and 3/32”.

3.

•

•

•

•

•

4.

4.

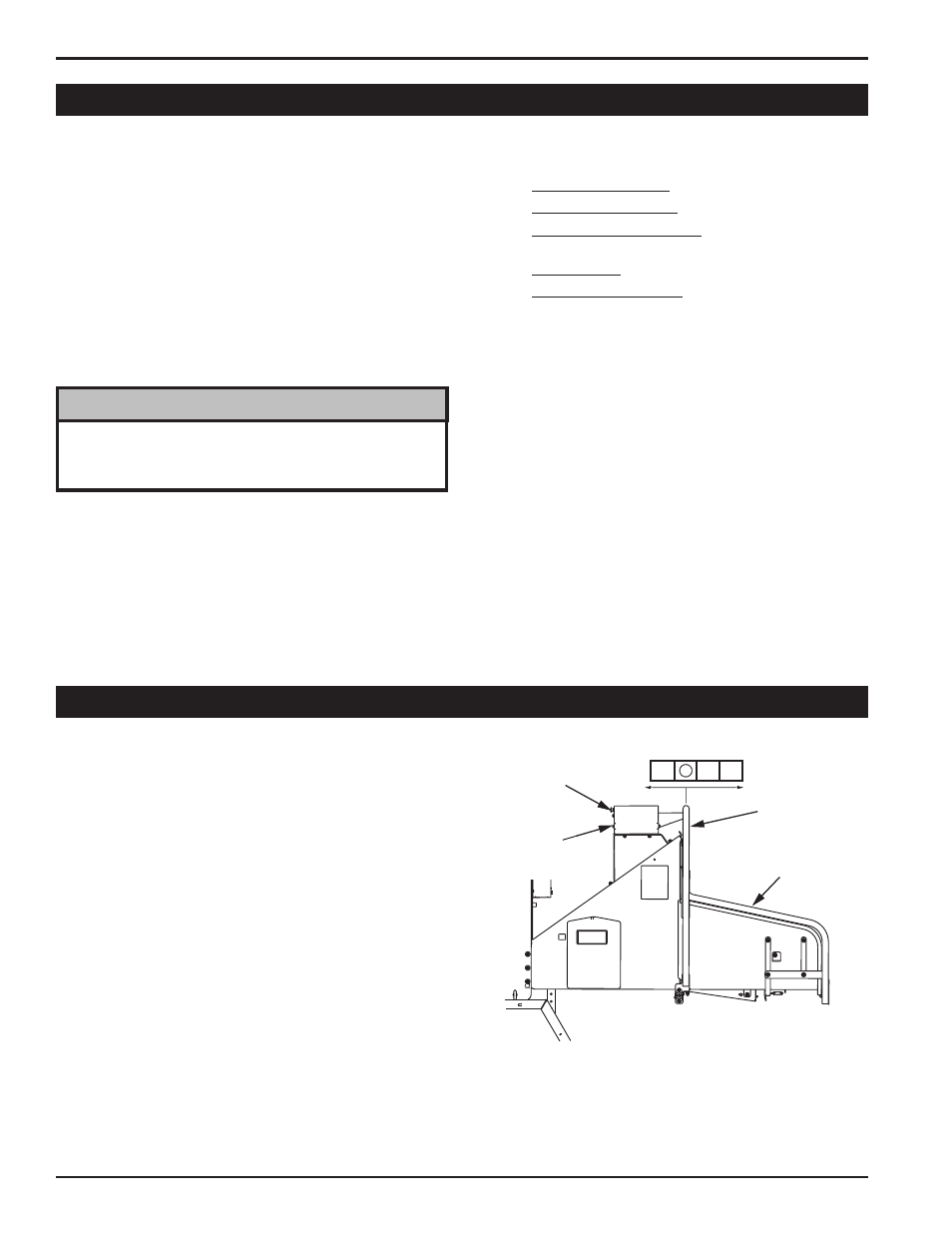

4.8 fEED RoLLER coNTRoL bAR

opERATINg

Start the chipper engine. Bring the machine to 1/4 operating

speed (Section 4.1).

Slowly release engagement handle to engage the drive

belt.

Bring the machine to full throttle.

Engage the hydraulic feed by moving the control bar as

shown in Figure 4.3.

If the chipper jams, reverse the feed by moving the control

bar to the reverse position. Remove the branch and rotate

it before reinserting into the chute again.

1.

2.

3.

4.

5.

Figure 4.3 - Control Arm Operation

The feed roller control bar is used to manually control the rota-

tion of the feed roller.

FORWARD (F) rotation is used to move material into the feed

chute towards the chipper blades.

REvERSE (R) rotation is used to push material out of the feed

chute away from the chipper blades.

STOP is used to halt the rotation of the feed roller.

SAFETY BAR

(S & F MODELS)

RESET/OVERRIDE

BUTTON

(S & F MODELS)

SAFETY BAR

ACTIVATED

(S & F MODELS)

R

REVERSE

R

F

FORWARD

STOP

REVERSE

CONTROL BAR

It is important to bring the engine to full RPM before oper-

ating the chipper. The chipper feed controller requires the

chipper disk to turn at full RPM in order to operate.

NoTE