Hydraulic feed, 1 hydraulic feed instructions, 2 control arm operation – Echo 71854 User Manual

Page 15: Warning, Caution

8 INCH PTO CHIPPERS

13

4.2 conTrol arm oPeraTion

1. engage the PTO. Bring the chipper up to operating

speed. See Section 3, "controls and Operation," for

starting, chipping and stopping instructions.

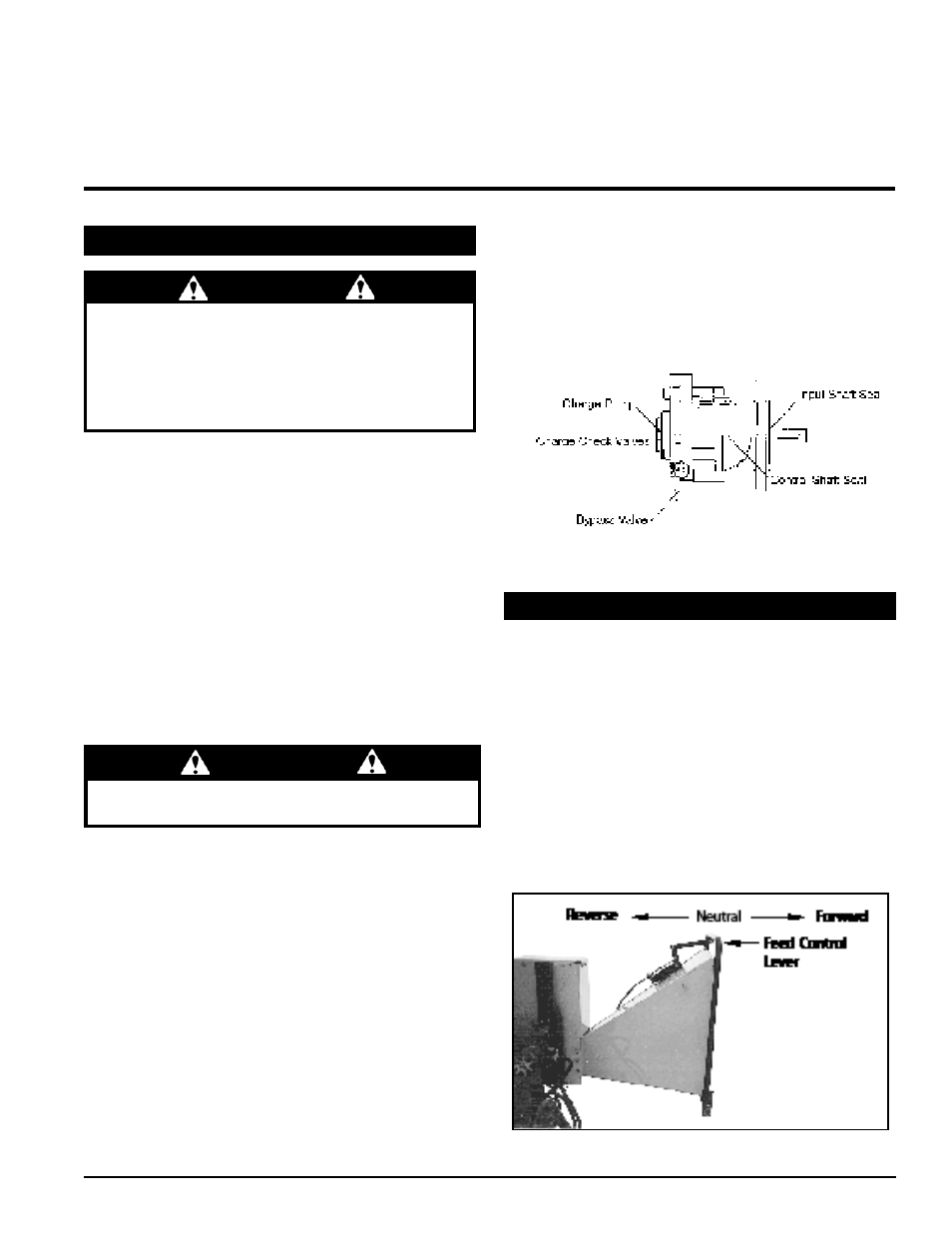

2. engage the hydraulic feed by moving the control arm

as shown in figure 4.2. in the forward direction, the

feed rate increases as the arm is moved.

3. feed the branch (up to eight or nine inches in diameter,

depending on model number).

4. If the chipper jams, reverse the feed by moving the

control arm in the reverse direction. remove the branch

and rotate it before inserting it into the chute again.

Figure 4.2, Control arm operation

4.1 HYdraulic Feed insTrucTions

4.1.1 Fluids

Premium hydraulic fluids containing high quality rust,

oxidation and foam inhibitors are required. These include

premium turbine oils, aPi cd engine oils per Sae J183,

M2c33f or g automatic transmission fluids meeting allison

c-3 or caterpillar TO-2, and certain specialty agricultural

tractor fluids.

4.1.2 HYdrosTaTic PumP sTarT uP Procedure

follow this start-up procedure when starting a new

installation or when restarting an installation in which the

hydrostatic pump has been removed from the system.

1. Before starting the hydrostatic pump, make sure all sys-

tem components (reservoir, fittings, etc.) are clean.

2. fill the reservoir with recommended hydraulic fluid,

which should be filtered before entering the reser-

voir.

3. The inlet line leading from the reservoir to the charge

pump must be filled before start-up. loosen the fitting

on this inlet line until oil bleeds out.

4. Start the engine and run at the lowest possible rPM.

5. as air is purged from the unit, the oil level in the res-

ervoir will drop and bubbles may appear in the fluid.

refill the reservoir as necessary.

6. run the unit in both directions for several minutes until

any remaining air is purged from the unit. refill the

reservoir as necessary.

do not start engine unless pump is in neutral or detent

position on the cable.

Warning

HYdraulic Feed

Section

cauTion

handle pressurized hydraulic fluid carefully. escaping

pressurized hydraulic fluid can have sufficient force to

penetrate your skin causing serious injury. This fluid

may also be hot enough to burn. Serious infection or

reactions can develop if proper medical treatment is

not administered immediately.

7. a motor fitting may have to be loosened and oil-bled

to remove air from the system (use same procedures

as steps 3-5).

8. disengage PTO, check for and correct any fluid leaks,

and check the reservoir level. add fluid if necessary.

The hydrostatic pump is now ready for operation.

Figure 4.1, Hydrostatic pump components

4