12 lifting and tie down, Lifting - outrigger lifting rings, 12 lifting and tie down -25 – JLG X500AJ Operator Manual User Manual

Page 75: Lifting - outrigger lifting rings -25, Lifting machine - lifting rings location -25

SECTION 4 - MACHINE OPERATION

3121636

– JLG Lift –

4-25

4.12 LIFTING AND TIE DOWN

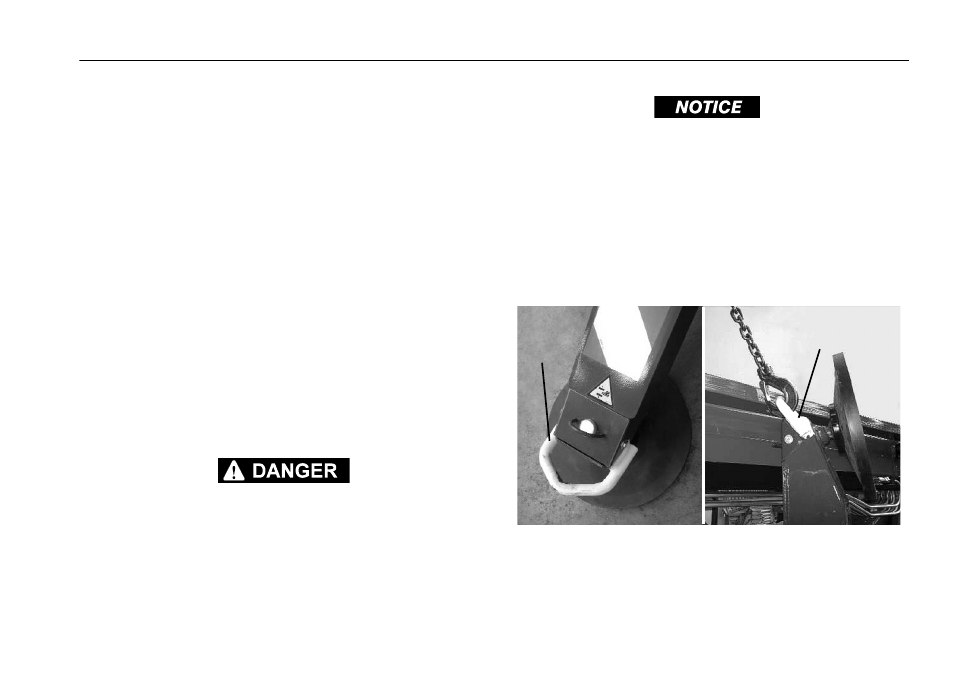

Lifting - Outrigger Lifting Rings

1. Determine gross weight of machine, refer to the

serial number tag, or weigh the individual unit to

find out the gross vehicle weight.

2. Configure the machine in the transport position;

a. place the booms in the stowed position and

properly aligned

b. all outriggers are fully retracted

c. tracks are fully widened

d. Remove all loose items from the machine

3. Lift machine using only the lifting rings provided

on the end of the outrigger arm, at the outrigger

pad.

4. Properly adjust the rigging to prevent damage to

the machine and so the machine remains level and

balanced.

TO LIFT THE MACHINE A SEPARATE WIRE ROPE/CHAIN/SLING MUST BE

ATTACHED TO EACH OF THE (4) LIFTING RINGS USING THE APPROPRIATE

LIFTING POINTS AS INDICATED IN FIGURE 4-6. OTHERWISE THE

MACHINE MAY NOT BALANCE PROPERLY AND MOVE UNEXPECTEDLY.

THE USE OF ROPES, CHAINS OR SLINGS WITH LENGTH LESS THAN 10 ft.

(3m) COULD CAUSE PERMANENT DAMAGE TO THE MACHINE OUTRIG-

GERS.

As the weight of the machine is not spread equally over the

four outriggers, the minimum required capacity of the four

ropes, chains or slings used must be: no less than 4,409 lb.

(2000 kg) and their length no less than 10 ft. (3m) and all

identical.

Figure 4-6. Lifting Machine - Lifting Rings Location

1. Lifting Rings (4 - 1 Each Outrigger)

1

1