Lubrication, Lubrication -7, Hydraulic oil specifications -7 – JLG X500AJ Operator Manual User Manual

Page 117

SECTION 6 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

3121636

– JLG Lift –

6-7

FOLLOW THE LUBRICATION INTERVALS INDICATED AND USE ONLY THE

RECOMMENDED LUBRICANTS IN ORDER TO PROTECT PINS AND CONNEC-

TIONS FROM WEAR.

Lubrication

(See Figure 6-1.)

Hydraulic Oil

NOTE:

When adding or replacing hydraulic oil only use JLG

approved hydraulic oil. Do not mix oils unless directed

by JLG.

Recommended Gearbox Oils

600 XP 150

EP 150

Blasia 150

Spartan EP150

Engine Oil

SAE 10W30

Greasing and Lubrication

Recommended lubricants

Contact Grease EP (blue in color) be used to grease the turn-

table and cylinder pins on the chassis

GR MU EP1 Grease be used to grease the expansion guide of

the chassis, the track tension valve, and basket support pins

White EP NLGI 2 Grease be used on the boom extensions

Either MU EP1 or Esso Beacon EP2 be used to grease the

coupler and belt tensioner

Greasing Locations (See Figure 6-1.)

NOTE:

Use a brush to spread grease onto telescopic boom

wear pad areas.

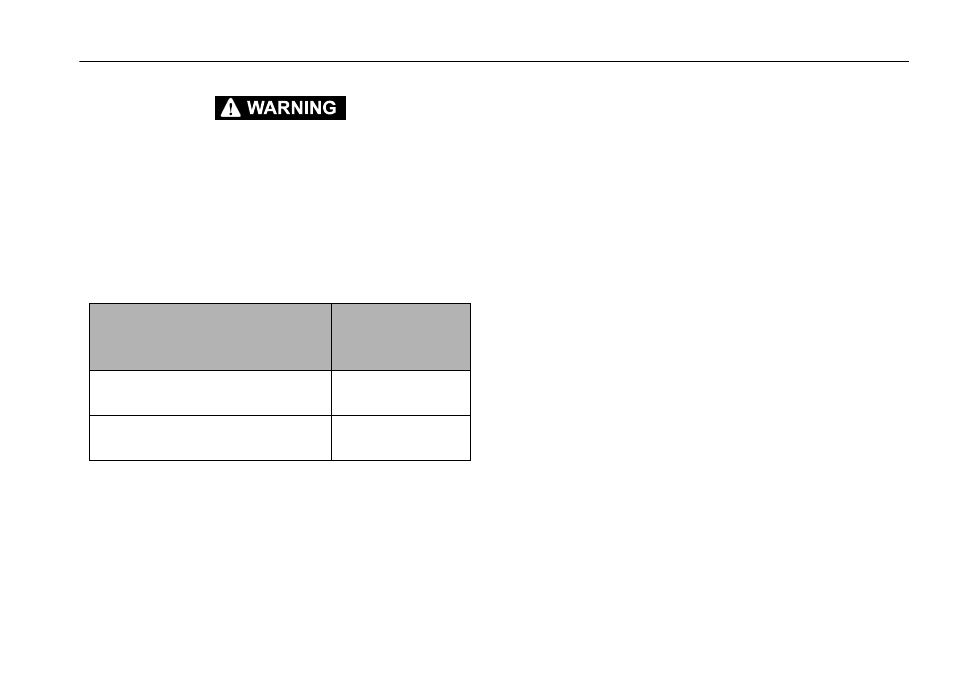

Table 6-9. Hydraulic Oil Specifications

Hydraulic System

Operating

Temperature Range

Viscosity

Grade

14deg F (-10 deg C) and

104deg F (+40deg C)

ISO VG 46

14deg F (-10 deg C) or

above 104deg F (+40deg C)

ISO 68