Chevy 4.3l v-6 engine tj wrangler motor mounts – Advance Adapters 713096 User Manual

Page 4

ADVANCE ADAPTERS INC.

P/N 713096

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447

PAGE 4 OF 4

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

03-17-04

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

CHEVY 4.3L V-6 ENGINE

TJ WRANGLER MOTOR MOUNTS

Exhaust:

All of the stock exhaust system must be removed for the V-6 conversion. New pipe

should be run from the manifolds all the way out. Routing the exhaust around the

frame should not be a problem. If you are doing an E.F.I. smog legal conversion, you

may need to find a stock GM vehicle to measure the location of where the oxygen

sensors and cats are located on the stock pipes. Also make sure proper heat shielding

is used between exhaust components and the floorboard. Use the stock “donor” ve-

hicles’ exhaust size as a start for your new system. For pollution controlled vehicles,

please refer to the owner’s manual for the stock exhaust configuration.

Headers are also a good choice for this conversion. They fit very well with these mounts and add to the performance

look of your TJ. Recommended headers are AA Part No. 717056 and are NOT for pollution controlled vehicles.

Fuel System:

Refer to the fuel section of your Jeep owner’s manual before servicing or taking apart any piece of the fuel system.

Special fittings, pressurized line, and certain procedures must be taken into consideration before work can be done on the

fuel system.

Do not take short cuts on fuel systems.

The new GM fuel systems run mainly high pressure out of the

pumps. Only approved high pressure hose and fittings should be used. Take care when routing fuel lines, and make sure

all fittings are secure. The newer engines require around 3/8” line on the pressure side, and around 5/16” on the return

(3/8” is O.K. for the return line). The stock Jeep fuel pump comes close to feeding the new block, but could fall short.

The stock Jeep fuel pump is internally regulated in the fuel tank at 46 psi. Check the fuel pressure needed to run the new

V-6 block (both P.S.I. and G.P.M.). Keep in mind that since the Jeep regulated the pressure at the tank, it did not run a

return fuel line.

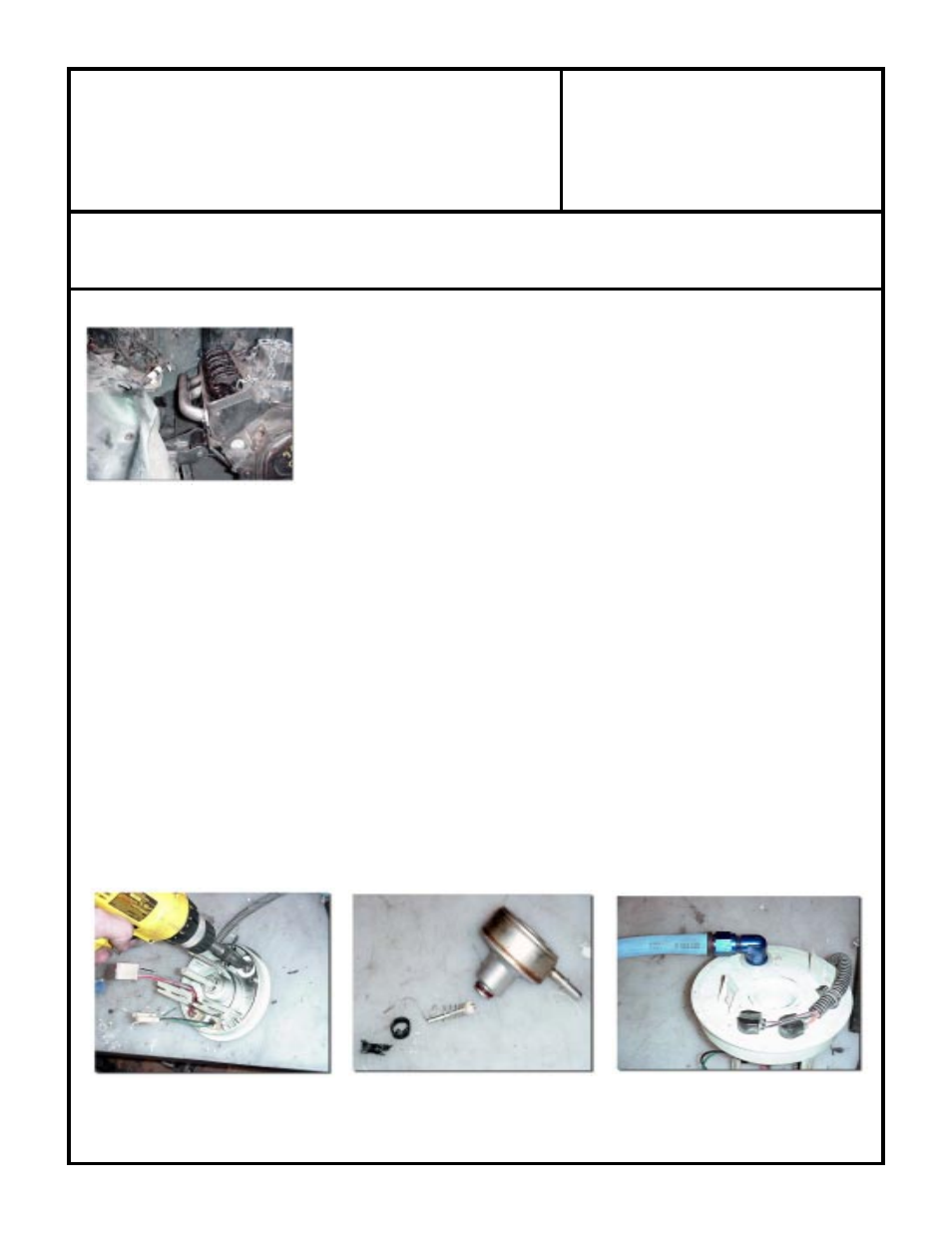

We opted to run two new 3/8” lines, one pressure and one return. The pressure line needs to be installed by drilling and

installing a bulkhead-type “AN” fitting alongside the stock Jeep pump assembly. A fuel tank pick up must also be installed.

Make sure the new pick up line draws from the bottom of the tank and has no restrictions. The old Jeep “pressure” line

out of the tank can be used as a return line connection from the 4.3. To use this connection you must take all the “guts”

out of the stock internal regulator. The photos on this page show the modifications we did.