Advance Adapters 50-9000 User Manual

Page 6

ADVANCE ADAPTERS INC.

P/N: 50-9000

P.O. Box 247, 4320 Aerotech Center Way

New Item: (9/09)

Paso Robles, CA 93447

PAGE

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will

void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend

that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a

service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive

dealerships and parts stores.

LAND ROVER SERIES T-CASE to NP

CIRCULAR 6 ADAPTER with JEEP 23 SPLINE

03-25-10

Necessary sheet metal modifications:

To maintain the original external appearance of the vehicle and allow for ample cooling capacity the “breakfast” or headlight

panel will need to be modified. The original radiator will not be adequate to keep the replacement engine cool. To make room

for a larger radiator the original radiator support structure needs to be removed. The original radiator overhangs the first cross

member.

The panel is easily modified. Drill through the spot welds and gently lever the two pieces apart. To maintain structural rigidity,

you can use three pieces of 1/8"X 1" flat bar stock. One across the top, spanning the width of the panel, and the two remaining

pieces will be welded vertically and parallel to the center opening. The latch is no longer used.

You will need to purchase military hood latches. This provides the space for a radiator on

top of the first cross member.

It is advisable to convert to power steering. When converting to power steering, the steering

relay is removed.

To provide room for a “V” type engine and maintain the original look of the vehicle

It is necessary to widen the firewall or “bulkhead” to accept the wider engine. This is easily

done by drilling out the spot welds that hold the center panel to the foot well. Remove the

panels individually and save them for reuse. Drill out the spot-welds of the inner kick panel.

The goal is to match to foot well dimensions to the driver side (LHD). Essentially creating

a large factory appearing opening. Fabricate a new center panel keeping in mind the bell

housing size, depending upon engine, transmission and placement .

6 OF

6

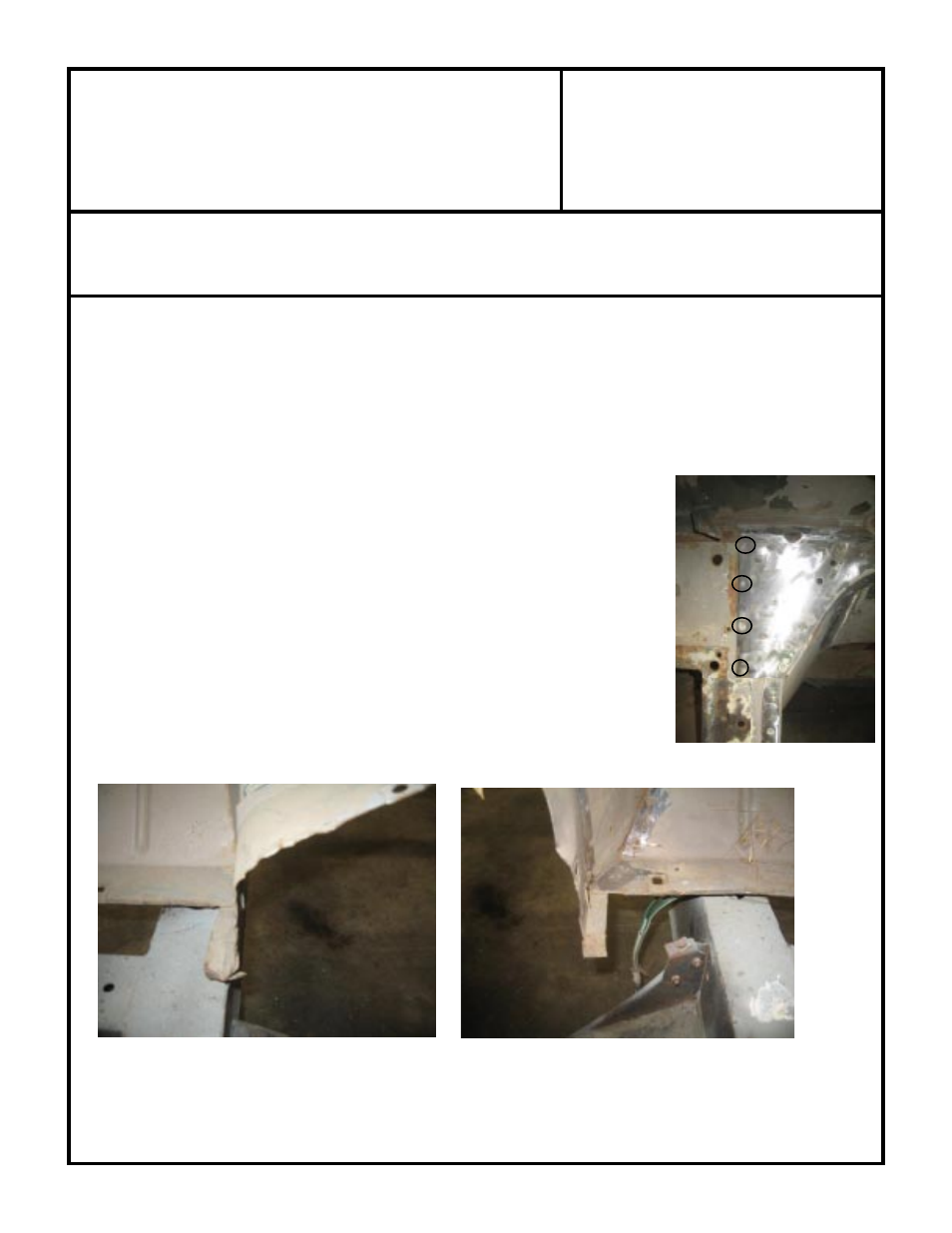

Images of the foot well panels ( left side and then the right)

Bulkhead spot welds