Caution – Snorkel TB85J User Manual

Page 38

Chapter 7 – Prestart Inspection

34

TB80/TB85J – 0112477

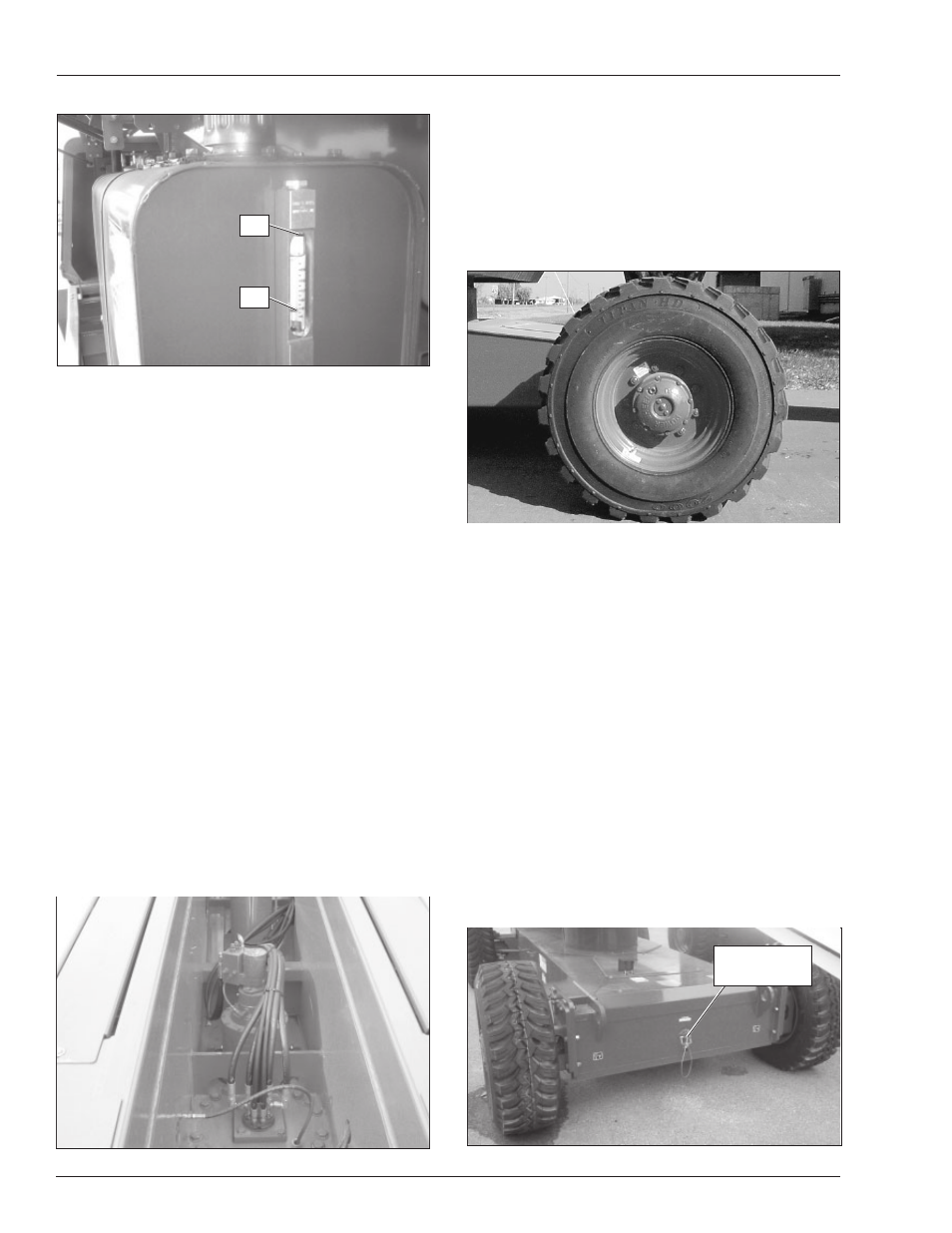

Figure 7.9 – Fluid Level Indicator

A

Caution

Not all hydraulic fluid is suitable to use in the hy-

draulic system. Some have poor lubricating char-

acteristics and can increase component wear. Only

use hydraulic fluid as recommended.

If necessary, remove the filler cap and add fluid of the

proper type. Refer to Chapter 2 for the proper type and

grade of hydraulic fluid to use. The need to regularly add

fluid indicates a leak that should be corrected.

The sight glass on the reservoir has an internal thermom-

eter to measure the fluid temperature. The temperature

should be less than 200°F (93°C).

Fluid Filter

Checking the condition of the hydraulic fluid filter is part

of the machine maintenance schedule and should not be

performed by the operator.

Hoses, Tubes, and Fittings

Inspect all hydraulic hoses, tubes, and fittings for wear,

leakage, or damage (refer to Figure 7.10). Make sure the

hoses are properly routed to avoid sharp edges, kinking,

and scuffing. Inspect the tubes for dents or other damage

that may restrict fluid flow. Make sure all hoses and tubes

are held firmly in their support brackets.

Figure 7.10 – Hoses, Tubes, and Fittings

Hydraulic fluid leaks are easily visible on the ground.

Check under the chassis for fluid that has leaked.

Tires and Wheels

Visually inspect the tires and wheels (refer to Figure 7.11)

to make sure they are suitable for service. Check the

wheel lug nuts to see that none are missing, damaged,

or loose.

Figure 7.11 – Tires and Wheels

The aerial platform has foam filled tires. Foam filled tires

do not have a pressure decal or a valve core.

Inspect for large holes or cuts where foam is coming out

of the tire. Look for large imbedded objects, such as angle

iron, that can rip a tire open.

Punctures caused by bolts, screws, or nails are not a

problem for foam filled tires.

Axle/Boom Interlock

Test for proper operation of the axle/boom interlock sys-

tem from the lower controls with no material or personnel

in the platform.

With the axles retracted and the pin properly locked in

position in the top hole (refer to Figure 7.12), operate the

boom up and extend functions. The boom should only

raise to a few degrees above horizontal and it should only

extend approximately one foot.

Figure 7.12 – Rear Axles Retracted

Full

Add

Pin Locked In

Top Hole