Troubleshooting 10 – Lukas MSM-2D mobile control module User Manual

Page 19

19

Troubleshooting

10.

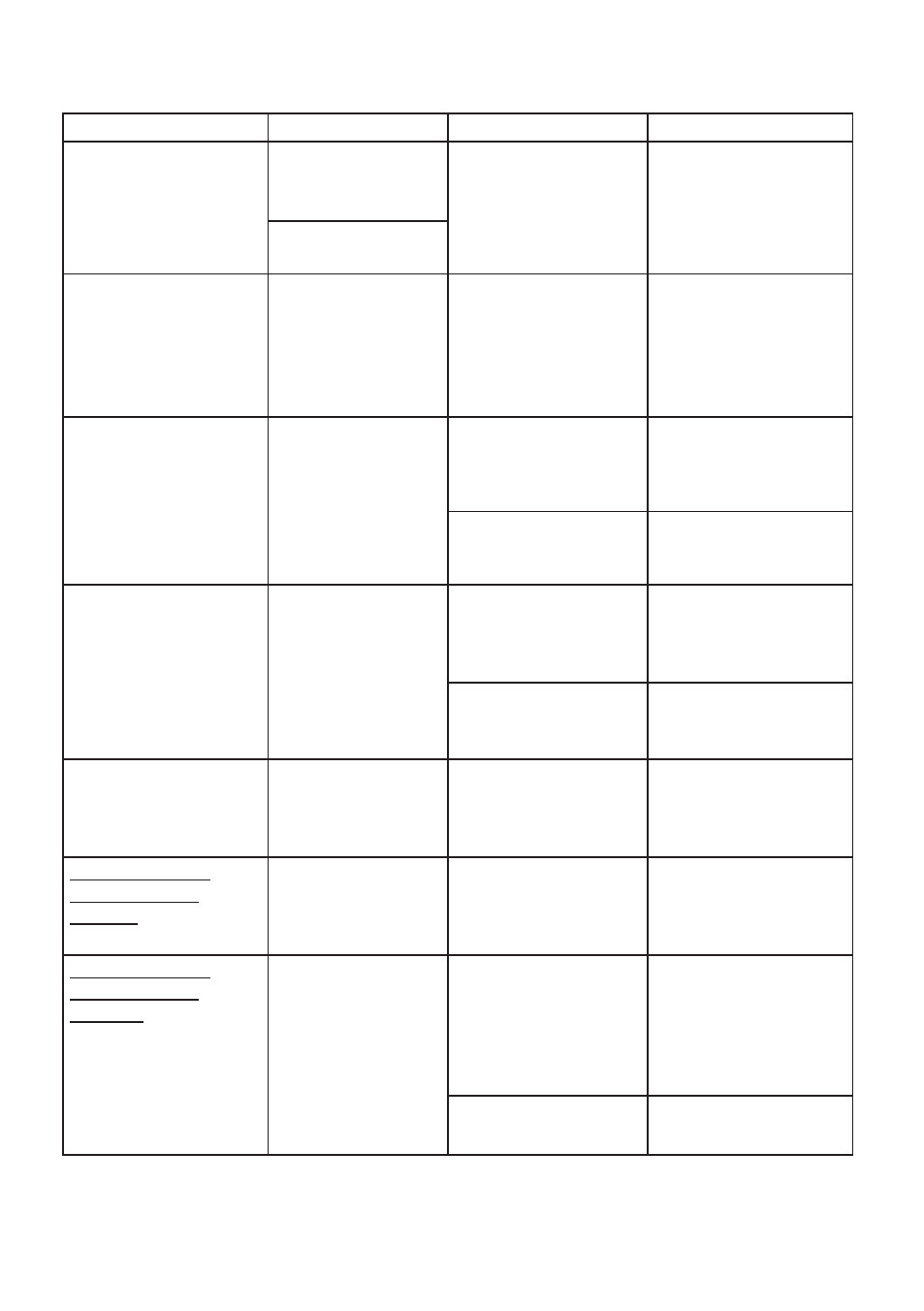

Trouble

Check

Cause

Solution

Piston of the

hydraulic cylinder is

moving slowly or with

jerks

Hose lines

properly

connected?

Air in the hydraulic

system

Venting pump system

Pump unit

running?

System pressure

(high pressure) is not

reached:

Pump pumping

smoothly? Hose

lines connected?

Adjustment pressure

on the “pressure

relief valve for

extension” too

low due to setting

behaviour.

Have the adjustment

performed by an

authorised dealer or

directly by LUKAS.

Cylinder pistons

extend, but do not

retract

Pump pumping

smoothly?

Cylinder pistons

extending? Hose

lines properly

connected?

Adjustment pressure

on the “pressure

relief valve for

retraction” too low.

Have the adjustment

performed by an

authorised dealer or

directly by LUKAS.

Charge retaining

valve blocked

Repair by authorised

dealers or by LUKAS

directly!

Pistons of the

cylinders do not

extend or retract

Hose lines

properly

connected?

Control valve in

home position

(depressurised

circulation)

Turn the star grip of

the control valve into

the desired direction

of travel.

Control valve

defective

Repair by authorised

dealers or by LUKAS

directly!

The piston of a

cylinder is not

extending or

retracting

Hose lines

properly

connected?

Distribution valve

not set to the

corresponding

cylinder

Turn distribution

valve to control

the corresponding

cylinder.

In the case of a

monocoupling

system: Hose lines

cannot be connected

Coupling defective

Coupling should be

replaced immediately

In the case of a

monocoupling

system: Hose lines

frequently cannot

be connected or are

difficult to connect

Check the

viscosity and the

use temperature of

the hydraulic fluid

used.

Hydraulic fluid

not suited to the

application

Hydraulic fluid needs

to be changed

(see the chapter

“Hydraulic fluid

recommendation” for

more information)

Coupling defective

Coupling should be

replaced immediately