2 operation of the mobile selection manifold – Lukas MSM-2D mobile control module User Manual

Page 12

12

7.1.1 Installing system components

Procedure:

1. First, set up the hydraulic unit in a suitable location, i.e. on a flat surface at a safe distance

from the load to be lifted.

2. Then, set up the hydraulic cylinders that are to raise the load.

ATTENTION!

During the installation, make sure that:

- the base is anti-slip and level (if necessary, use a suitable base pad).

- the cylinders are never used without piston guard plates.

- the cylinders are stable (if necessary, use base plates or similar items).

- a pressure-tight, anti-slip base pad is always used between piston guard

plate and load lifting point.

3. Install the Mobile Selection Manifold at a safe distance from the load to be raised.

4. Connect the hydraulic cylinder to the Mobile Selection Manifold as described in the

"Connecting the equipment" chapter.

NOTE:

When using double-acting hydraulic cylinders, always first connect lines B1,

B2 and return line to the pump!

5. Connect the hydraulic unit to the Mobile Selection Manifold as described in the "Connecting

the equipment" chapter.

7.1.2 Preparing for operation

Procedure:

1. Check the fluid levels of the hydraulic unit

2. Make the hydraulic unit operationally ready. (see separate operating instructions of the

hydraulic unit)

3. Start the hydraulic unit

7.2 Operation of the Mobile Selection Manifold

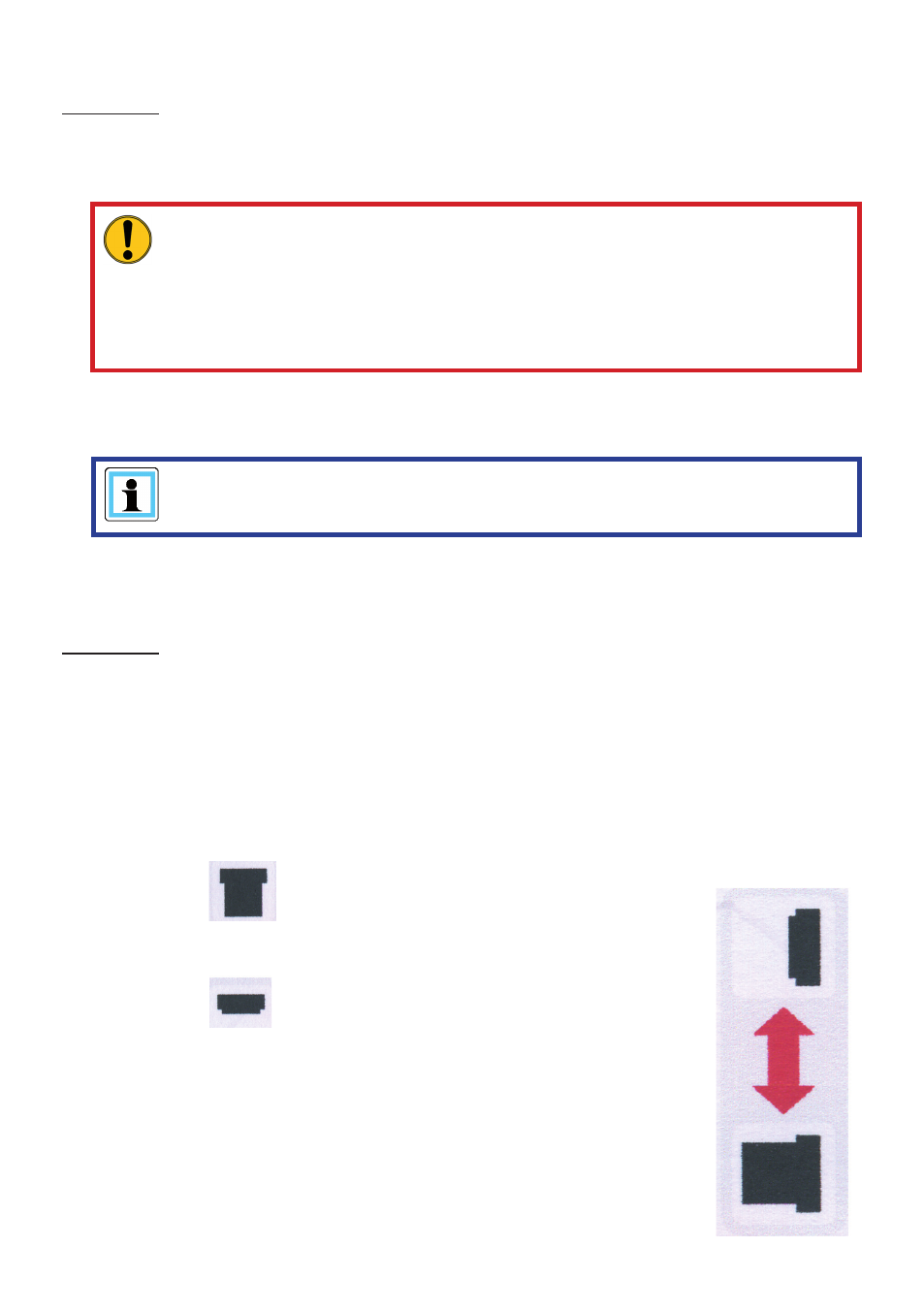

Extend piston ( ):

Turn star grip in the clockwise direction (in the direction of the

corresponding symbol) and hold it in this position.

Retract piston ( ):

Turn star grip in the anti-clockwise direction (in the direction of the

corresponding symbol) and hold it in this position.

“Dead man” circuit:

After it is released, the star grip automatically returns to the central

position with complete assurance of holding the charge.

7.2.1 Control valve (cover sheet, item 1)

The movement of the lift cylinder is determined with the control valve.