T-shoot – Class1 Digital Pressure Gauge User Manual

Page 5

page 5 of 6 pages

Engineering

Standards

Name

Identifier

Instructions

Engineering Standard Number

C1-102190-A

Digital Pressure Gauge

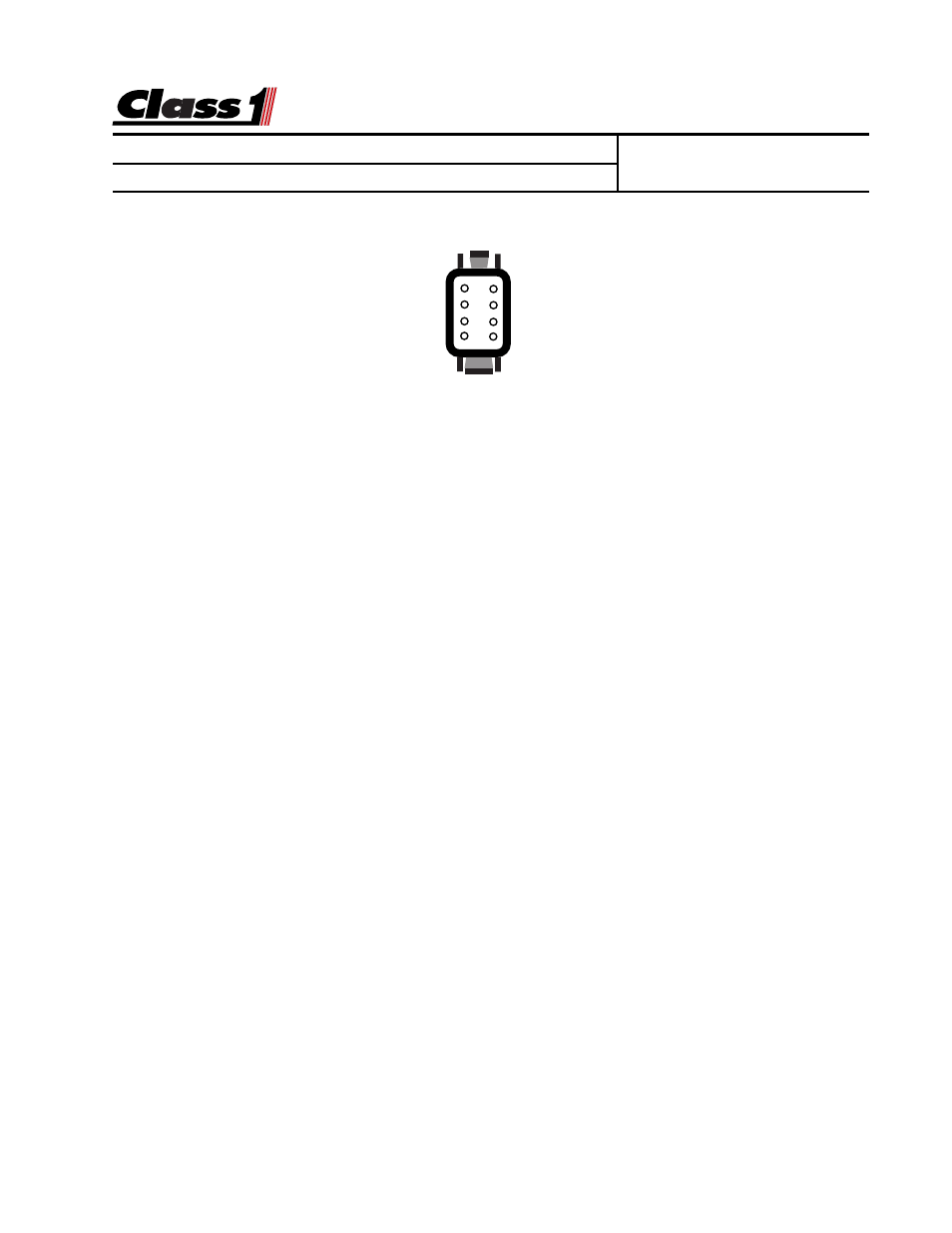

1

2

3

4

8

7

6

5

DTM06-08SA

0462-201-20141 20 Ga.

Wire Insertion View

Switch

8

Pulses IN

7

Sensor Ground

6

System Ground

5

1

N/C

2

PSI IN

3

Sensor +5/10 VDC

4

System Power

The display does not illuminate.

The display must have power at terminal 4 and ground at terminal 5.

With the connector removed, check across pins 4 and 5 for 12 VDC, if 12 volts is

present with the correct polarity, replace the display. If voltage and/or ground is

not present, check the vehicle wiring.

The pressure reading on a discharge or intake gauge does not change.

There is a problem with the pressure transducer or wiring. At the transducer

connector, check for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and must be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check for voltage at the

display between pin 6 (sensor ground) and pin 2 (signal). With zero pressure/

suction at the pump, this voltage should be between 500 mV and 900 mV. As the

pressure in the pump increases, the voltage should increase. If it does not, then

replace the transducer. If the voltage increases, and the display does not change,

perform a default calibration, call Class1 (1-800-533-3569) for instructions. If the

default calibration does not correct the problem, replace the display.

The pressure display reads

SEnS

.

There is a problem with the pressure transducer or wiring. At the transducer

connector, check for 5 VDC between pins A (ground) and pin B (+5 VDC). These

are sent from the display and must be of the correct polarity for the transducer to

function. Plug the connector into the transducer and check for voltage between

Pin A (sensor ground) and pin C (sensor signal) at the transducer. With zero

pressure/suction at the pump, this voltage should be between 500 mV and 900

mV, if it is not, replace the transducer. Check for voltage at the display between

pin 6 (sensor ground) and pin 2 (signal). With zero pressure/suction at the pump,

this voltage should be between 500 mV and 900 mV. If it is not, check the wiring

from the transducer to the display. If the correct voltage is present at pin 2,

replace the display.

T-shoot