AEM 30-5132M Analog Boost Metric Gauge User Manual

Page 3

Page 3

WHITE – The WHITE wire should be connected to the Analog + input on the

AEM EMS or the analog + input on a similar device.

BROWN – The BROWN wire should be connected to the Analog – input. If the

EMS or similar device does not have a – input, the BROWN wire should be connected

to a sensor ground. If no sensor ground is available, the BROWN wire should be

connected to a power ground. Note: The BROWN wire must be connected in order

to get correct readings from the analog output.

Gauge Start-Up

The boost gauge has an “auto zero” function that accommodates for variances in

atmospheric pressure. Upon powering up, the gauge will take an instantaneous

pressure reading, which will be used as the “zero point” on the faceplate. This allows

the needle position at atmospheric pressure to be “0” for all operating conditions. The

needle will display between 0-35 psi boost for pressures above the current atmospheric

level. The needle will display between 0-30 inHg for “vacuum” pressures below the

current atmospheric level.

Auto Zero Troubleshooting

If the gauge reads “0” or close to “0” while the engine is idling, the auto zero

pressure measurement is inaccurate. This is most likely caused by a power source that

is not on in the On, Run, and Crank positions.

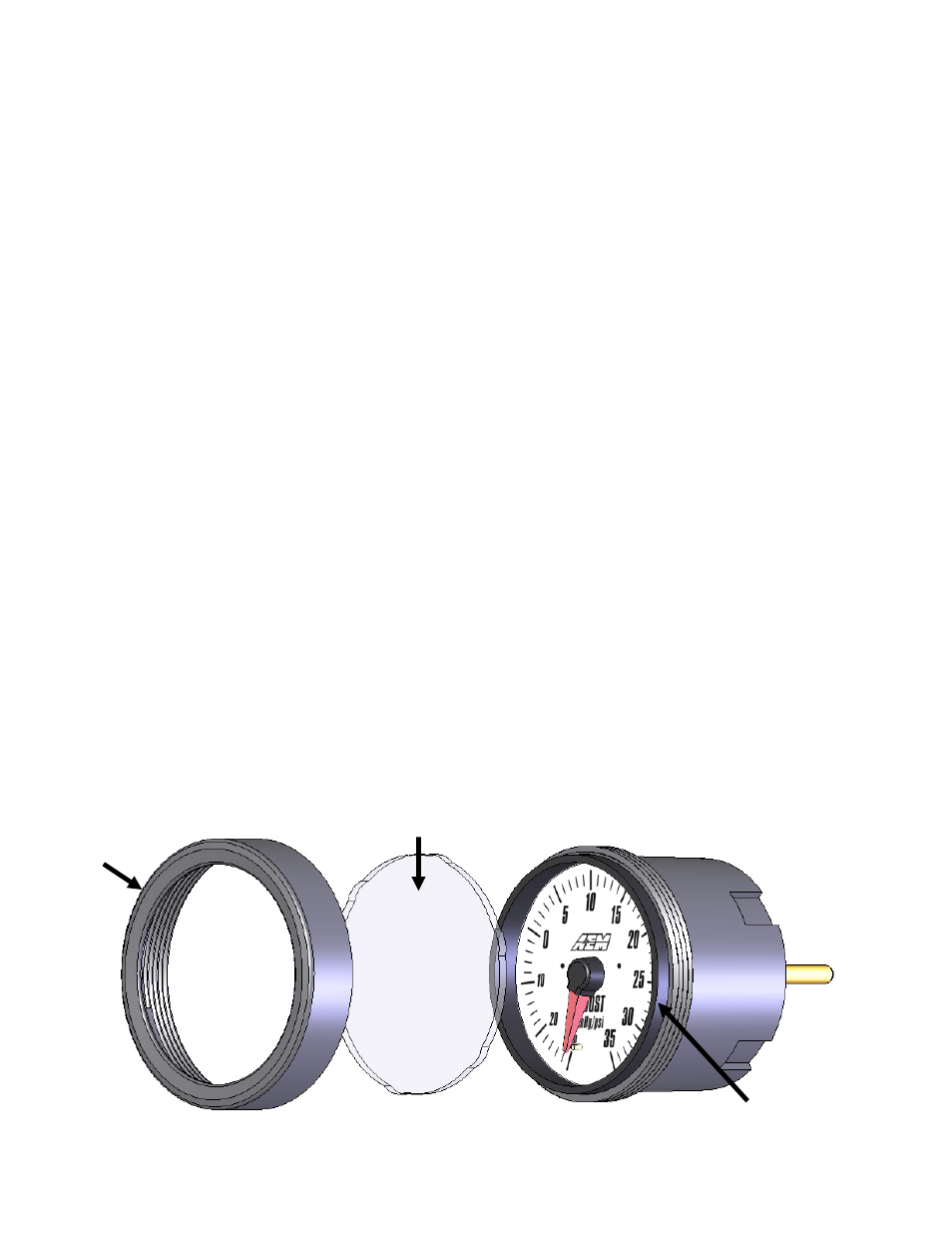

Changing the Bezel

The AEM Boost Gauge comes with the black bezel installed. However, a silver bezel is

also included in the gauge kit. To change the bezel, orient the gauge so you are looking

at the faceplate. Rotate the bezel counter-clockwise to unscrew it from the gauge cup.

The bezel, lens, and rubber spacer are all removable. Reassemble the gauge as

shown below in Figure 3. Note: When reassembling the gauge, it may be necessary to

apply a light amount of pressure on the lens and spacer to keep the faceplate from

rotating when reinstalling the bezel. Do not over tighten the bezel when

reassembling the gauge.

Figure 3. Changing Bezels

BEZEL

LENS

RUBBER

SPACER