Maintenance of the step slider, Trouble shooting/friction points – Rock-Slide Engineering TJ YJ LJ STEP SLIDER User Manual

Page 8

Installation Instruction RSEI 123

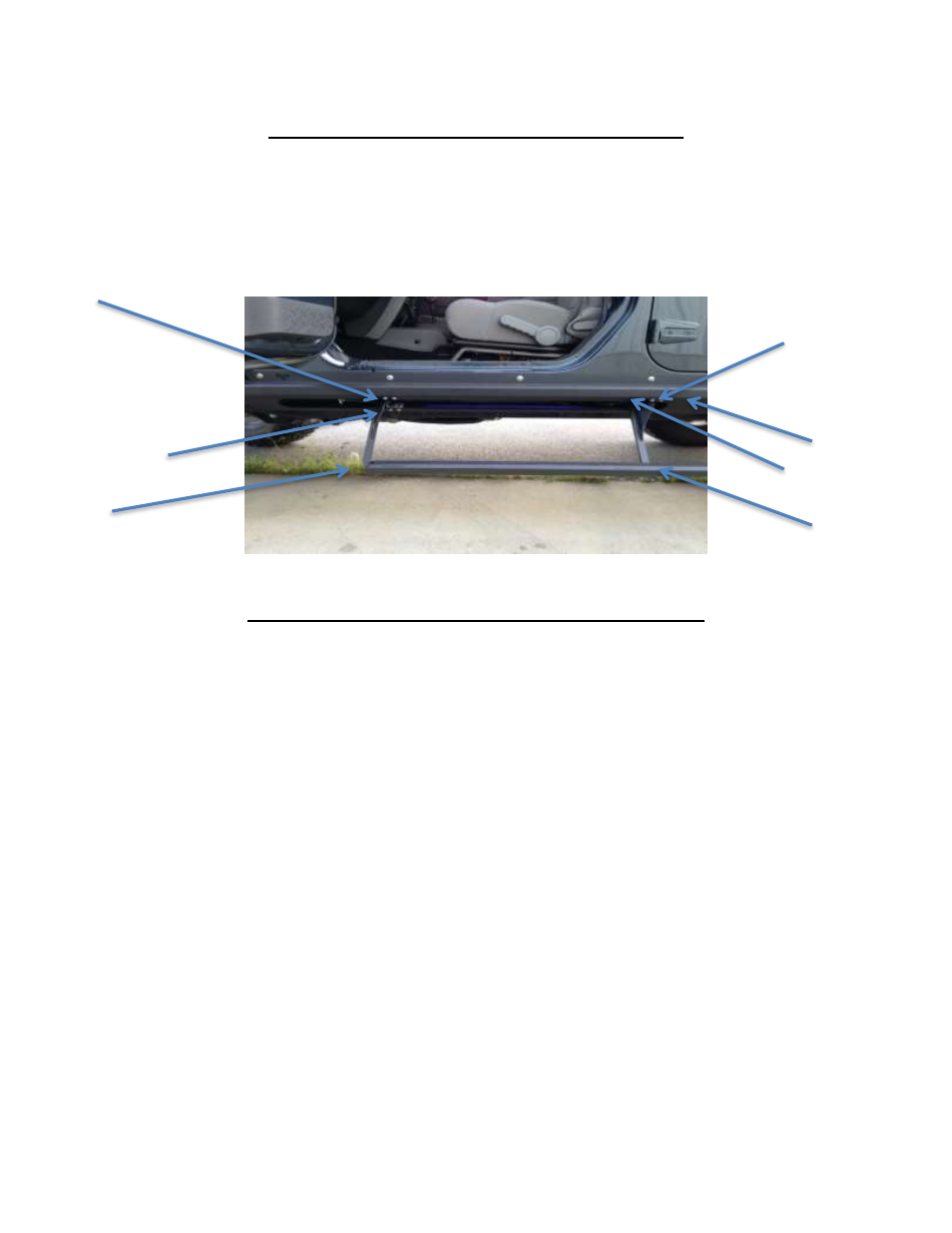

MAINTENANCE OF THE STEP SLIDER

Please note the slider is a mechanical mechanism that requires maintenance to operate

properly. To keep the slider operating at an optimal level it needs to be maintained

with lubrication. We recommend using a Teflon based lubrication on the 7 indicated

points below to keep the slider operating smoothly. A good rule of thumb is every time

you change your engine oil. Heavy trail use will increase the frequency in lubrication.

TROUBLE SHOOTING/FRICTION POINTS

The slider is powered by the Jeep’s battery when engine is off and powered by the Jeep’s

engine while the vehicle is running. This will cause the slider to operate at different

speeds depending on the Jeep engine is running or not.

If you feel the slider is sticking at certain points or the motor is stressing it may be

possible a friction point has developed during the install due to a variance in the slider

or Jeep construction.

o

To identify a friction point that may be stressing the slider motor, look at the

slider from outside the jeep and open and shut the Jeep door a couple of times

and study the way the slider operates. Look at the slider for wear in the powder

coating. The slider leaves our manufacturing facility with a perfect powder

coating so if you see a spot on the slider that has scratches or the powder coating

shows a blemish; that’s a good indication of a friction point. Using a file or other

grinding tool to smooth over a small area on the slider can alleviate this

problem.

Thank you for choosing Rock-Slide Engineering products. We value your business and

welcome your feedback/suggestions. If you have any concerns please contact us directly @

435-752-4580. We are here to help you!