Troubleshooting, Start--up checklist, Step 13 — system information – Bryant 604D--A User Manual

Page 28

28

repairing refrigerant leaks, replacing refrigerant components such

as filter drier, pressure switch, metering device, coil, accumulator,

or reversing valve.

Synthetic Roof Precautionary Procedure

1. Cover extended roof working area with an impermeable

polyethylene (plastic) drip cloth or tarp. Cover an

approximate 10x10 ft (3x3 m) area.

2. Cover area in front of the unit service panel with a terry

cloth shop towel to absorb lubricant spills and prevent

run--offs, and protect drop cloth from tears caused by tools

or components.

3. Place terry cloth shop towel inside unit immediately under

component(s) to be serviced and prevent lubricant run--offs

through the louvered openings in the unit base.

4. Perform required service.

5. Remove and dispose of any oil contaminated material per

local codes.

Liquid Line Filter Drier

The biflow filter drier is specifically designed to operate with

Puron. Use only factory--authorized components. Filter drier must

be replaced whenever the refrigerant system is opened. When

removing a filter drier, use a tubing cutter to cut the drier from the

system. Do not unsweat a filter drier from the system. Heat from

unsweating will release moisture and contaminants from drier into

system.

Puron (R--410A) Refrigerant Charging

Refer to unit information plate and charging chart. Some R--410A

refrigerant cylinders contain a dip tube to allow liquid refrigerant to

flow from cylinder in upright position. For cylinders equipped

with a dip tube, charge Puron units with cylinder in upright

position and a commercial metering device in manifold hose.

Charge refrigerant into suction--line.

Step 13 — System Information

Loss of Charge Switch

The loss of charge switch is a protective device wired into control

circuit (low voltage). It shuts off the compressor if abnormally low

pressures are present in the refrigeration circuit.

NOTE:

Because these switches are attached to refrigeration

system under pressure, it is not advisable to remove this device for

troubleshooting unless you are reasonably certain that a problem

exists. If switch must be removed, remove and recover all system

charge so that pressure gauges read 0 psi. Never open system

without breaking vacuum with dry nitrogen.

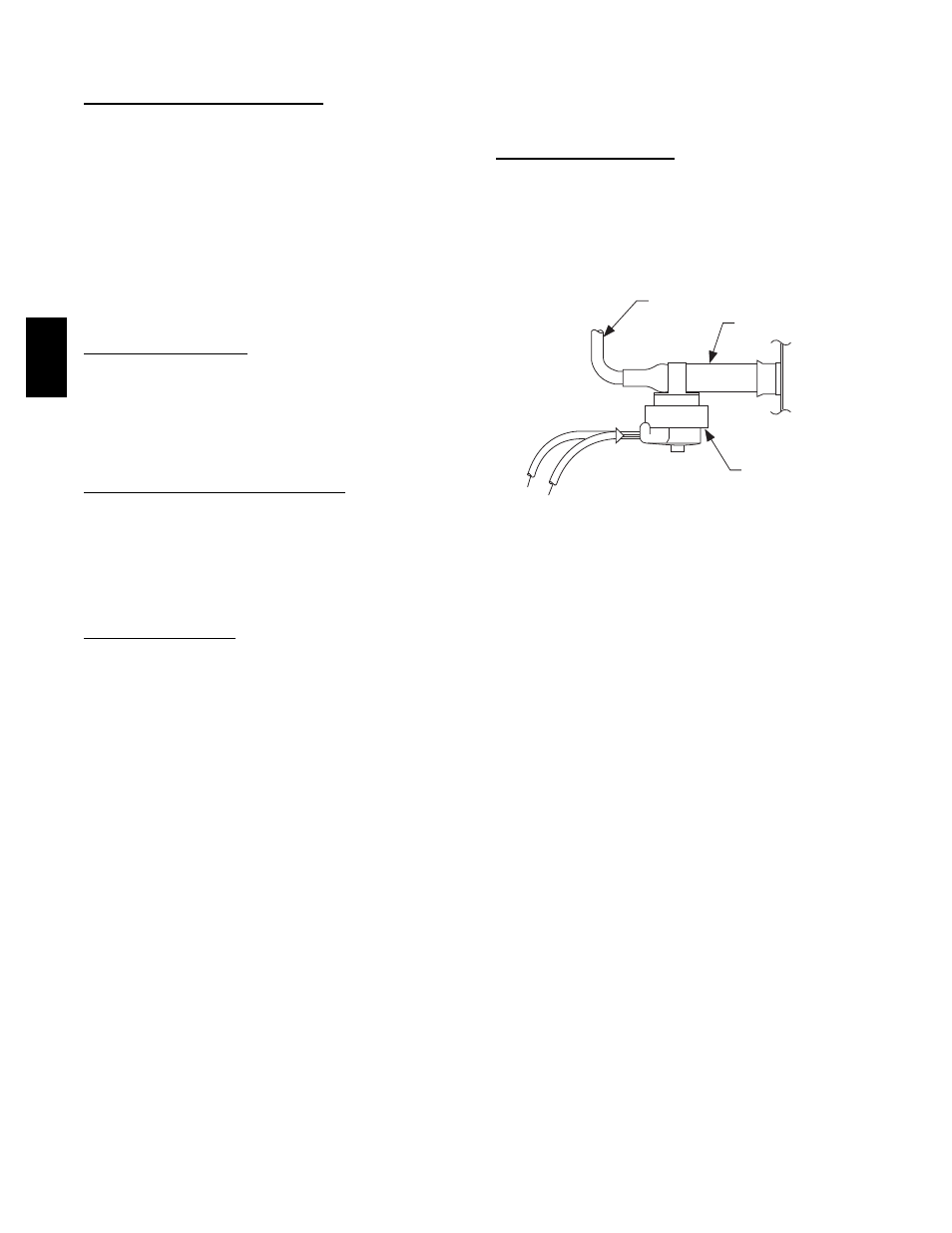

Check Defrost Thermostat

The defrost thermostat signals heat pump that conditions are right

for defrost or that conditions have changed to terminate defrost. It

is a thermally actuated switch clamped to outdoor coil to sense its

temperature. Normal temperature range is closed at 32_ 3_F (0

1.7_C) and open at 65_ 5_F (18 2.8_C).

NOTE: The defrost thermostat is usually located on the lowest

liquid leaving circuit of the left condenser coil.

FEEDER TUBE

STUB TUBE

DEFROST

THERMOSTAT

C99029

Fig. 21 -- Defrost Thermostat

TROUBLESHOOTING

Refer to the Cooling and Heating Troubleshooting Chart (Table 9)

for troubleshooting information.

START--UP CHECKLIST

Use the Start--Up Checklist.

604D

--

--

A