Vii condensate drain line – Burnham CHG225 User Manual

Page 20

20

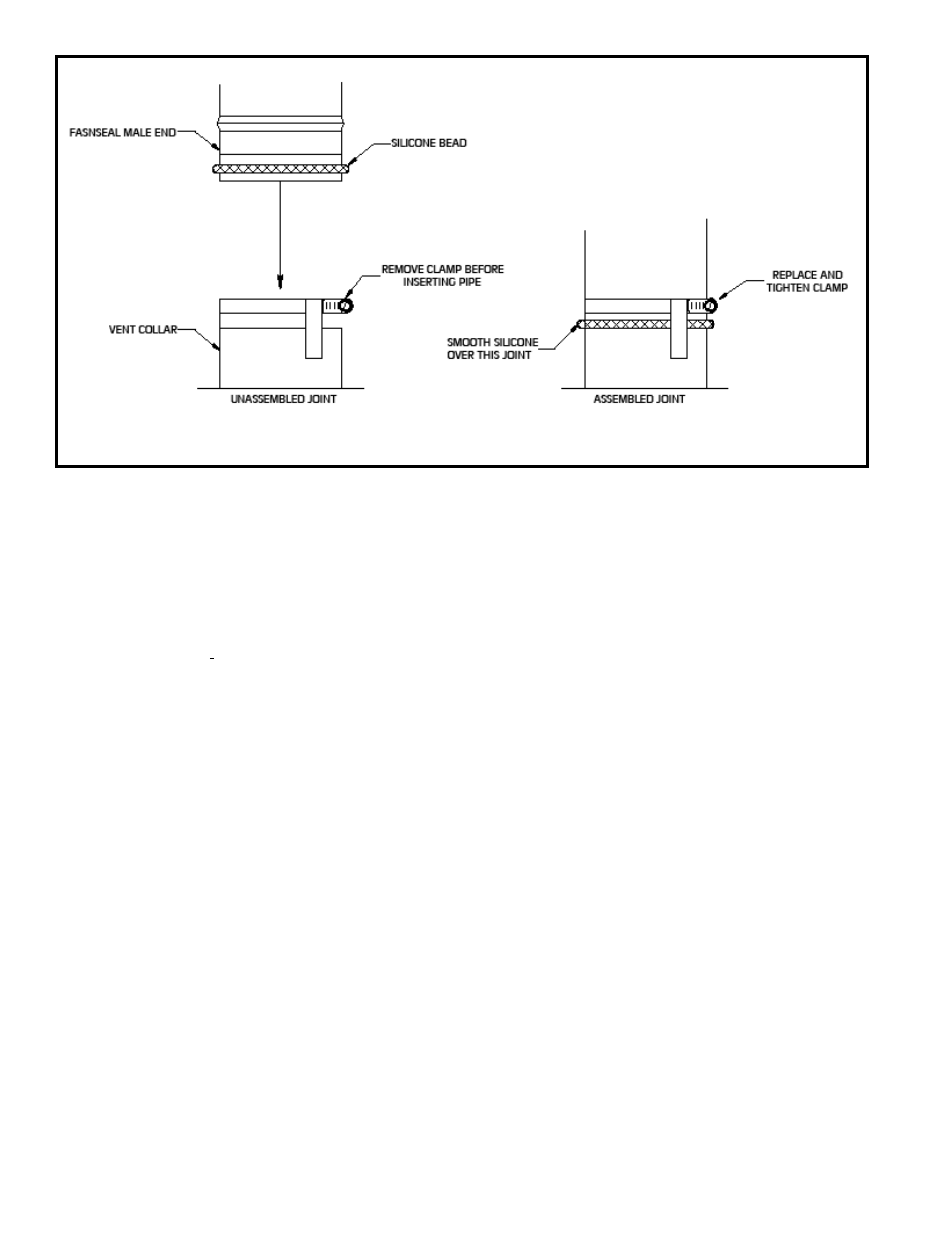

Figure 6.10: FasnSeal Connection to Vent Collar

VII Condensate Drain Line

1) All condensate which forms in the boiler or vent system collects in the sump under the heat exchanger and leaves

the boiler through the condensate trap. This trap allows condensate to drain from the sump while retaining flue gases

in the boiler. A length of drain hose is supplied with the boiler and is connected to the trap as shown in Figure 6.11.

This hose may be routed through the back of the boiler or to either side through the knockouts provided. Route this

hose to a drain or other suitable point for disposal. Note the following when disposing of the condensate:

a) If the condensate drain line must be extended, construct the extension from PVC or CPVC pipe. Insert the hose

provided with the boiler into the end of the extension as shown in Figure 6.11.

b) Condensate is slightly acidic. Do not use metallic pipe or fittings in the condensate drain line. Do not route the

drain line through areas that could be damaged by leaking condensate.

c) Some jurisdictions may require that the condensate be neutralized before being disposed of. Dispose of

condensate in accordance with local codes.

d) Do not route, or terminate, the condensate drain line in areas subjected to freezing temperatures.

e) If the point of condensate disposal is above the trap, it will be necessary to use a condensate pump to move

the condensate to the drain. In such cases, select a condensate pump that is approved for use with condensing

furnaces. If overflow from this pump would result in property damage, select a pump with an overflow switch

and use this switch to shut down the boiler. Alternatively, if heat is a necessity, use the overflow switch to trigger

an alarm.

f) Do not attempt to move the trap from the location shown in Figure 6.11. Do not attempt to substitute another trap

for the one provided with the boiler.

g) The vent shown in Figure 6.11 must be left open for the trap to work properly.