Bryant Series B 345MAV User Manual

Page 23

7. If improper venting is observed during any of above tests,

the venting system must be corrected.

Vent system or vent connectors may need to be resized. For any

other appliances when resizing vent systems or vent connectors,

system or connector must be sized to approach minimum size

determined in appropriate table in NFGC or NSCNGPIC.

II.

COMBUSTION-AIR AND VENT PIPING

A.

General

WARNING:

Solvent cements are combustible. Keep

away from heat, sparks, and open flame. Use only in

well-ventilated areas. Avoid breathing in vapor or allow-

ing contact with skin or eyes. Failure to follow this

warning could result in fire, property damage, personal

injury, or death.

Combustion-air and vent pipe fittings must conform to American

National Standards Institute (ANSI) standards and American

Society for Testing and Materials (ASTM) standards D1785

(schedule-40 PVC), D2665 (PVC-DWV), D2241 (SDR-21 and

SDR-26 PVC), D2661 (ABS-DWV), F628 (schedule-40 ABS), or

F891 (PVC-DWV cellular core) or F441 schedule-40 CPVC pipe)

and F438 (schedule-40 CPVC fittings). Pipe cement and primer

must conform to ASTM standards D2564 or F493 (PVC or CPVC)

or D2235 (ABS).

In Canada construct all combustion-air and vent pipes for this unit

of CSA or ULC certified schedule-40 PVC, PVC-DWV or

ABS-DWV pipe and pipe cement. SDR pipe is NOT approved in

Canada.

B.

Combustion Air Pipe

CAUTION:

Combustion air must not be taken from

inside a structure that is frequently contaminated by

halogens, which include fluorides, chlorides, bromides,

and iodides. These elements are found in aerosols,

detergents, bleaches, cleaning solvents, salts, air freshen-

ers, adhesives, paint, and other household products.

Locate combustion-air inlet as far as possible from

swimming pool and swimming pool pump house.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

NOTE:

Furnace combustion-air connections are sized for 2-in.

pipe. The combustion-air pipe will be 2-in. diameter in all

installations.

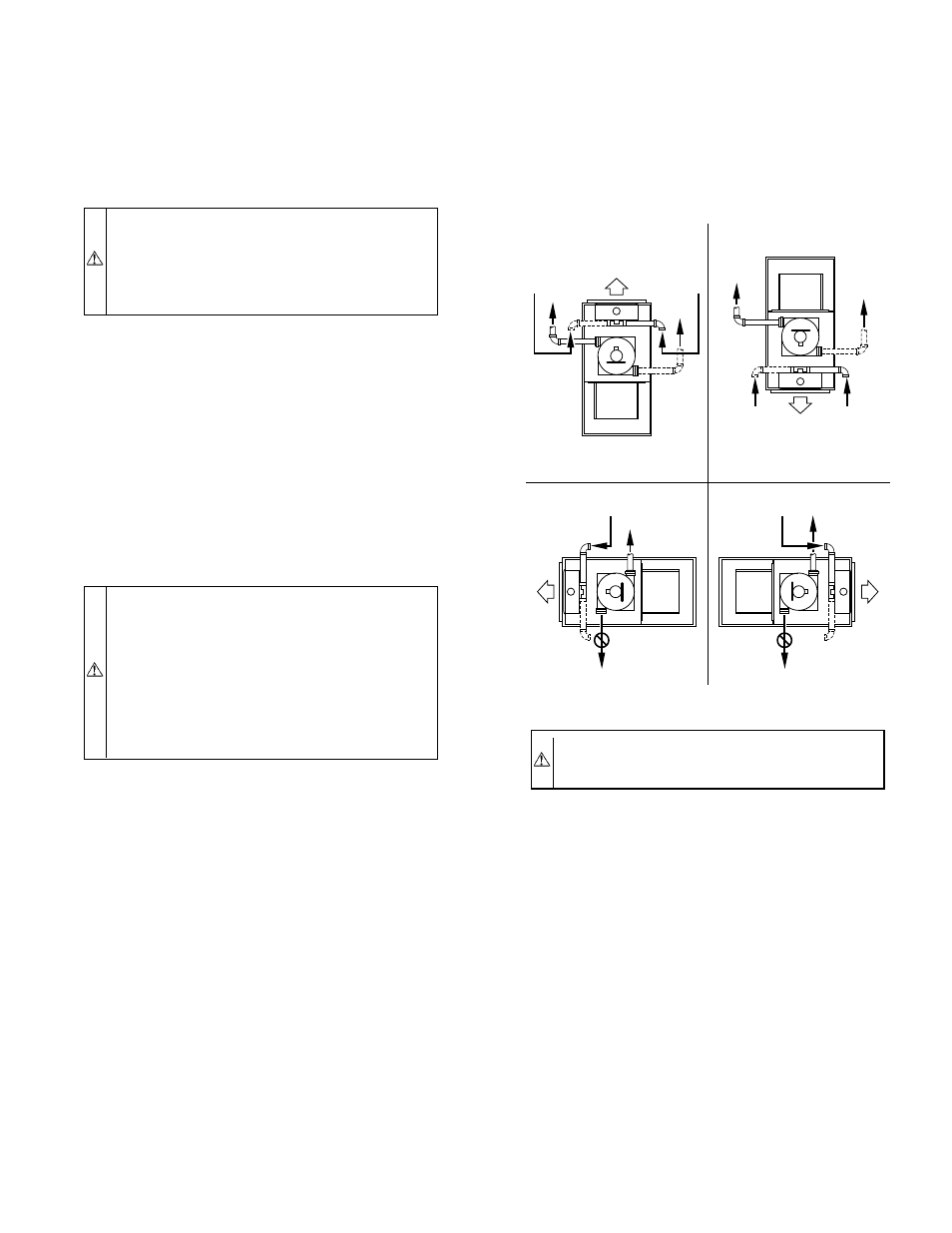

Furnace combustion-air connection must be attached as shown in

Fig. 28. Combustion-air intake housing plug may need to be

relocated in some applications.

Combustion-air pipe must terminate outside of furnace casing with

1 elbow. Orient elbow so that opening faces down for upflow or

downflow applications. Orient elbow so that it faces sideways (left

or right) for horizontal left or horizontal right applications. (See

Fig. 28.) Maintain a 3-in. minimum clearance between the opening

of the combustion-air inlet pipe and any object.

NOTE:

All pipe joints must be watertight except attachment of

combustion-air inlet pipe to inlet housing connection, since it may

be necessary to remove pipe for servicing.

Install combustion air inlet pipe as follows:

1. Assemble combustion-air inlet pipe.

a. Permanently install perforated disk assembly (factory-

supplied in loose parts bag) in combustion-air elbow

using RTV or by cementing. (See Fig. 29.)

For 120,000 Btuh size units only: Separate the 2 halves

of perforated disk assembly and use only the shouldered

disk half.

b. Determine length of straight portion of combustion-air

inlet pipe from table in Fig. 29.

c. Cut field-supplied 2-in diameter PVC pipe to determined

length.

d. Permanently attach elbow/perforated disk assembly to

straight portion of pipe using RTV or by cementing. (See

Fig. 29.)

2. Attach combustion-air inlet pipe.

a. Determine location of combustion-air intake pipe con-

nection to combustion-air intake housing as shown in

Fig. 28 for application.

b. Reposition combustion-air intake housing plug fitting in

appropriate unused intake housing connection.

c. Install pipe support (factory-supplied in loose parts bag)

into selected furnace casing combustion-air pipe hole.

Pipe support should be positioned at bottom of casing

hole.

d. Insert assembled combustion-air inlet pipe into intake

housing.

e. Make sure elbow is oriented in an acceptable direction

and that the minimum clearance of 3 in. is observed. (See

Fig. 28.)

f. Drill a 1/8-in. hole in 2-in. combustion-air inlet pipe

using hole in intake housing as a guide.

g. Install a field-supplied No. 6 or No. 8 sheet metal screw

into combustion-air pipe.

Fig. 28—Combustion-Air and Vent Pipe Connections

CAUTION:

Make sure there is adequate clearance (3-in.

minimum) to any fixed or loose objects in order to ensure

an adequate combustion-air supply.

A96188

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW

DOWNFLOW

HORIZONTAL-LEFT DISCHARGE

HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

NOTE:

Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

VENT

VENT

VENT

—23—

→