Bryant Series B 345MAV User Manual

Page 17

D.

Return Air Connections

1. Upflow Furnaces

The return-air duct must be connected to bottom, sides (left or

right), or a combination of bottom and side(s) of main furnace

casing as shown in Fig. 1. Bypass humidifier may be attached into

unused side return air portion of the furnace casing. DO NOT

connect any portion of return-air duct to back of furnace casing.

2. Downflow and Horizontal Furnaces

The return-air duct must be connected to return-air opening

provided as shown in Fig. 1. DO NOT cut into casing sides or back

to attach any portion of return-air duct. Bypass humidifier connec-

tions should be made at ductwork or coil casing sides exterior to

furnace.

VI.

FILTER ARRANGEMENT

CAUTION:

Never operate unit without a filter or with

blower access panel removed.

Factory-supplied washable framed filters are shipped in blower

compartment. Determine location for filter and relocate filter

retaining wire if necessary. See Table 1 to determine correct filter

size for desired filter location. Table 1 indicates filter size,

location, and quantity shipped with this furnace. See Fig. 2 for

location and size of bottom and side return-air openings.

CAUTION:

Air delivery above 1800 CFM requires that

both sides, a combination of 1 side and bottom, or bottom

only of furnace be used for return air.

NOTE:

Side return-air openings can ONLY be used in UPFLOW

configurations. Install filter(s) as shown in Fig. 20.

Bottom return-air opening may be used with all 4 orientations.

Filter may need to be cut to fit some furnace widths. Install filter

as shown in Fig. 21.

NOTE:

Remove and discard bottom closure panel when bottom

inlet is used.

VII.

BOTTOM CLOSURE PANEL

These furnaces are shipped with bottom enclosure panel installed

in bottom return-air opening. This panel MUST be in place when

side return air is used.

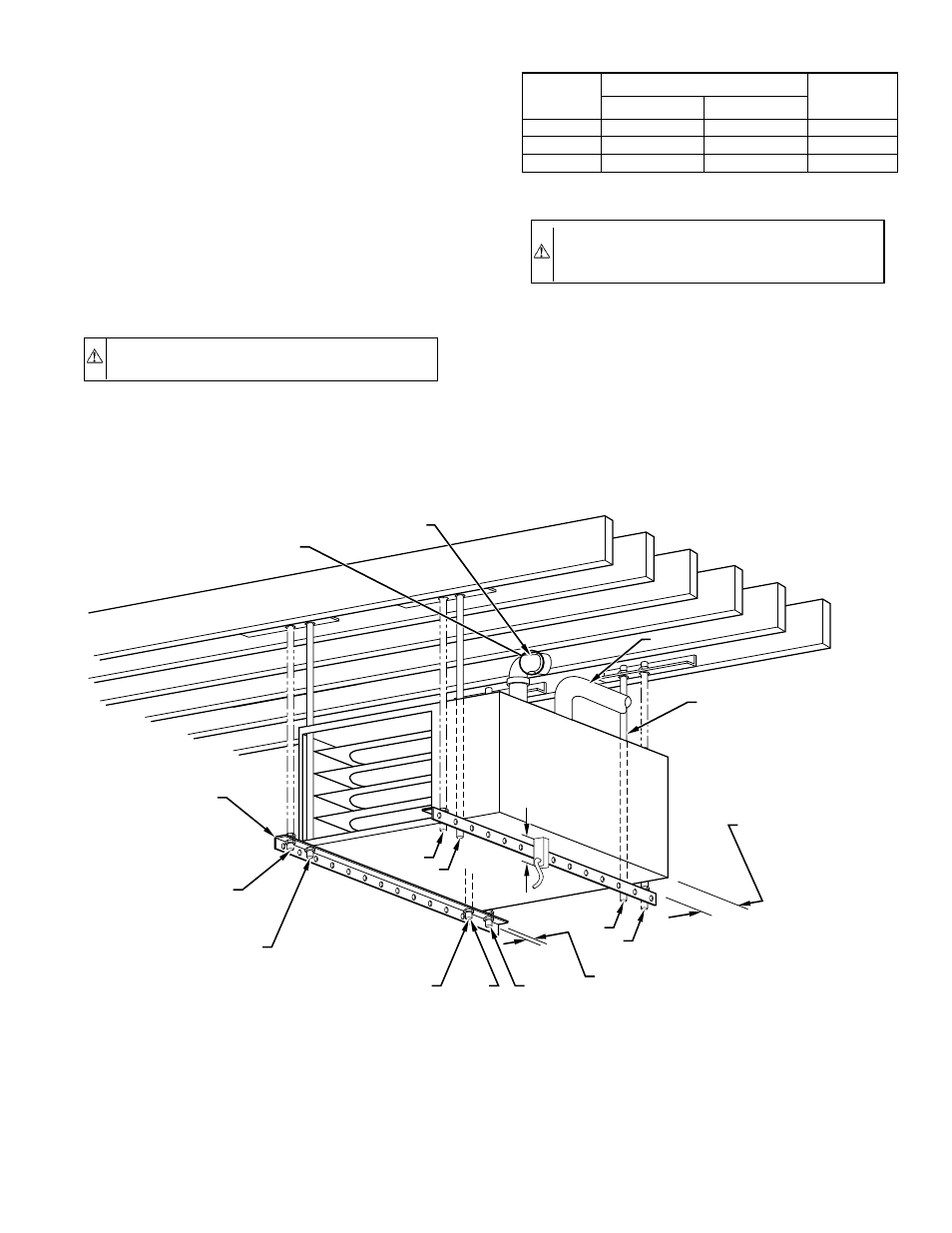

Fig. 19—Crawlspace Horizontal Application

A96209

NOTES:

ANGLE

IRON OR

EQUIVALENT

(B)

(A) ROD LOCATION

USING DIMPLE

LOCATORS

(SEE DIMENSIONAL

DWG FOR

LOCATIONS)

13

/

16

-IN. MAX

ALTERNATE SUPPORT

LOCATION FROM BACK

ALTERNATE SUPPORT

LOCATION 4-IN. MIN

8-IN. MAX

A 3-IN. MINIMUM

CLEARANCE TO

COMBUSTION-AIR INTAKE

IS REQUIRED.

3

⁄

8

-IN. ROD

(A)

(B)

(A)

(B)

(B)

(A)

1. A 1 In. clearance minimum between top of

furnace and combustible material.

2. The entire length of furnace must be

supported when furnace is used in

horizontal position to ensure proper

drainage.

3. Bottom side combustion-air entry cannot

be used when furnace is installed with

hangers as shown.

(A) PREFERRED ROD LOCATION

(B) ALTERNATE ROD LOCATION

DRAIN

5

3

⁄

4

″

3

/

8

-IN. HEX NUT

& WASHER (4)

REQD PER ROD

VENT

COMBUSTION-AIR

INTAKE

TABLE 1—FILTER INFORMATION

FURNACE

CASING

WIDTH (IN.)

FILTER SIZE (IN.)*

FILTER TYPE

FRAMED

Side Return

Bottom Return

17-1/2

(1) 16 X 25 X 1†

(1) 16 X 25 X 1

Cleanable

21

(1) 16 X 25 X 1

(1) 20 X 25 X 1†

Cleanable

24-1/2

(2) 16 X 25 X 1†

(1) 24 X 25 X 1

Cleanable

* Filters can be field modified by cutting frame as marked and folding to

desired size. Alternate sizes can be ordered from your distributor or dealer.

† Factory-provided with furnace.

—17—