Bryant Gas 340MAV User Manual

Page 18

VI.

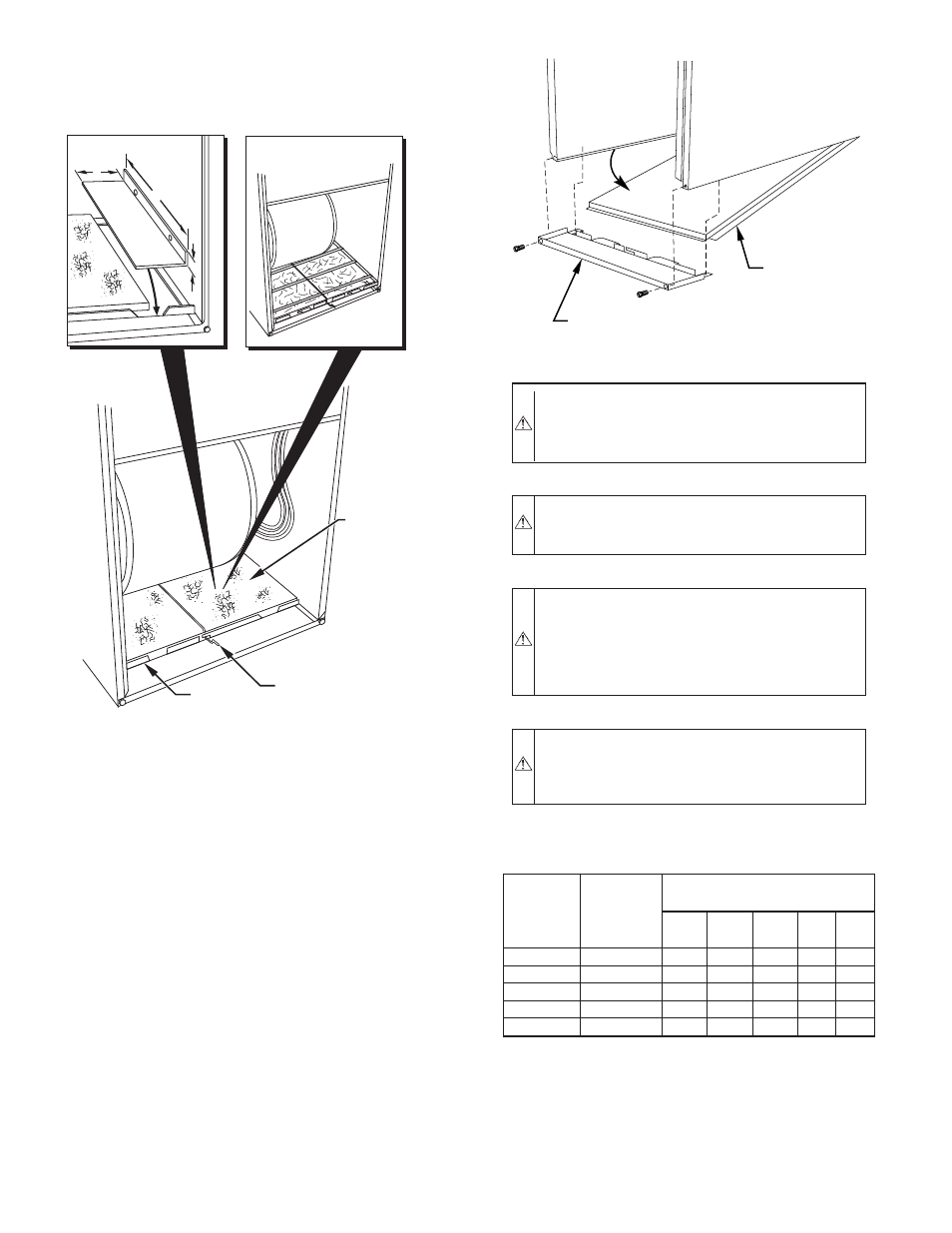

BOTTOM CLOSURE PANEL

These furnaces are shipped with bottom enclosure panel installed

in bottom return-air opening. This panel MUST be in place when

side return air is used.

To remove bottom closure panel, perform following:

1. Tilt or raise furnace and remove 2 screws holding front

filler panel. (See Fig. 25.)

2. Rotate front filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall front filler panel and screws.

VII.

GAS PIPING

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFGC in the United States.

Canadian installations must be made in accordance with NSCNG-

PIC and all authorities having jurisdiction. Gas supply line should

be a separate line running directly from meter to furnace, if

possible. Refer to Table 3 for recommended gas pipe sizing. Risers

must be used to connect to furnace and to meter. Support all gas

piping with appropriate straps, hangers, etc. Use a minimum of 1

hanger every 6 ft. Joint compound (pipe dope) should be applied

sparingly and only to male threads of joints. Pipe dope must be

resistant to propane gas.

CAUTION:

Connect gas pipe to furnace using a backup

wrench to avoid damaging gas controls. Failure to follow

this caution will result in intermittent unit operation or

performance satisfaction.

WARNING:

Gas valve shutoff switch MUST be facing

forward or tilted upward. Failure to follow this warning

could result in property damage or death.

WARNING:

Never purge a gas line into a combustion

chamber. Never test for gas leaks with an open flame. Use

a commercially available soap solution made specifically

for the detection of leaks to check all connections. A

failure to follow this warning could result in fire, explo-

sion, personal injury, or death.

WARNING:

Use proper length of pipe to avoid stress on

gas control manifold. Failure to follow this warning could

result in a gas leak resulting in fire, explosion, personal

injury, or death.

Install a sediment trap in riser leading to furnace. Trap can be

installed by connecting a tee to riser leading to furnace so

straight-through section of tee is vertical. Then connect a capped

nipple into lower end of tee. Capped nipple should extend below

level of gas controls. Place a ground joint union between gas

control manifold and manual gas shutoff valve. (See Fig. 26.)

Fig. 24—Bottom Filter Arrangement

A00290

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

17

1

⁄

2

-IN. WIDE

CASINGS ONLY:

INSTALL FIELD-SUPPLIED

FILTER FILLER STRIP

UNDER FILTER.

1

″

24

1

/

2

″

3

″

21-IN. WIDE

CASINGS ONLY:

SUPPORT RODS (3)

EXTEND 1/4" ON EACH

SIDE OF FILTER AND

REST ON CASING FLANGE

Fig. 25—Removing Bottom Closure Panel

A93047

BOTTOM

CLOSURE

PANEL

FRONT FILLER

PANEL

TABLE 3—MAXIMUM CAPACITY OF PIPE*

NOMINAL

IRON

PIPE

SIZE

(IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE (FT)

10

20

30

40

50

1/2

0.622

175

120

97

82

73

3/4

0.824

360

250

200

170

151

1

1.049

680

465

375

320

285

1-1/4

1.380

1400

950

770

660

580

1-1/2

1.610

2100

1460

1180

990

900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14-in. wc) or less, and

a pressure drop of 0.5-in. wc (based on a 0.60 specific gravity gas). Ref:

Table 12.2 NFPA 54-2002.

—18—

→