Bryant LOW-BOY 367AAN User Manual

Page 10

IV.

LIMIT CONTROL CHECK

After furnace has been in operation for at least 15 minutes, restrict

return-air supply by blocking filters or closing return registers and

allow furnace to shut down on high limit. The burner should shut

off, and main blower should continue to run.

Remove restriction, and burner should come back on in a few

minutes.

V.

FOR YEAR-ROUND AIR CONDITIONING

This furnace is designed for use in conjunction with cooling

equipment to provide year-round air conditioning. The blower has

been sized for both heating and cooling, however, fan motor speed

may need to be changed to obtain necessary cooling airflow.

VI.

HEATING

The blower speed is factory set to deliver required airflow at

normal duct static pressure.

VII.

COOLING

The blower speed may be field adjusted to deliver required airflow

for cooling application. (See Table 7.)

VIII.

CONSTANT BLOWER SWITCH

This furnace is equipped with a constant low-speed blower option.

Whenever room thermostat is not calling for heating or cooling,

blower runs on low speed in order to provide air circulation. If

constant blower option is not desired, the rocker switch on top of

cabinet may be used to turn off constant speed.

MAINTENANCE

WARNING:

The ability to properly perform mainte-

nance on this equipment requires certain expertise, me-

chanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance

on this equipment other than those procedures recom-

mended in the User’s Manual. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN POSSIBLE

DAMAGE TO THIS EQUIPMENT, SERIOUS PER-

SONAL INJURY, OR DEATH.

WARNING:

Before performing any service functions,

unless operations specifically require power to be on,

make sure all utilities are turned off upstream of appli-

ance. Failure to comply with this warning will cause a fire

hazard and/or bodily harm.

WARNING:

To avoid personal injury, make sure elec-

trical supply power is off before servicing. Failure to

follow this warning could lead to electrical shock, fire, or

death.

I.

GENERAL

In order to keep this furnace in good operating condition and to

maintain its warranty, the furnace MUST be serviced on an annual

basis. This servicing includes a nozzle change, a burner inspection,

a visual check of tube passages through flue outlet and cleanout

ports, and a visual inspection of combustion chamber when burner

is removed.

Depending on above inspection, service could also include a

cleaning and vacuuming of heat exchanger tubes and possibly the

heat exchanger drum section.

Removal of any heat exchanger components which are sealed by

gaskets requires replacement of gasket.

WARNING:

Failure to replace any heat exchanger gas-

kets with new gaskets when any heat exchanger plates or

covers are removed could lead to heat exchanger leakage,

sooting, and/or a hazardous condition capable of causing

bodily harm.

This furnace should never be operated without an air filter.

Disposable filters should be replaced at least once a year. If

equipped to provide cooling, filters should be replaced a minimum

of twice a year. Permanent filters should be cleaned at least twice

a year.

ALWAYS KEEP MAIN OIL VALVE TURNED OFF IF

BURNER IS SHUT DOWN FOR AN EXTENDED PERIOD OF

TIME.

II.

OIL BURNER

For optimum performance, oil burner nozzle should be replaced

once a year. Contact your service technician if you are unsure of

this procedure.

The procedure for nozzle installation and/or replacement is out-

lined in oil burner instruction manual which came with furnace.

After replacement of nozzle, burner should be adjusted in accor-

dance with Combustion Check section of this instruction.

III.

HEAT EXCHANGER AND FLUE PIPE

Ordinarily, it is not necessary to clean heat exchanger or flue pipe

every year, but it is necessary to have your service technician

check unit before each heating season to determine whether

cleaning or replacement of parts is required.

If cleaning is necessary, the following steps should be performed:

→

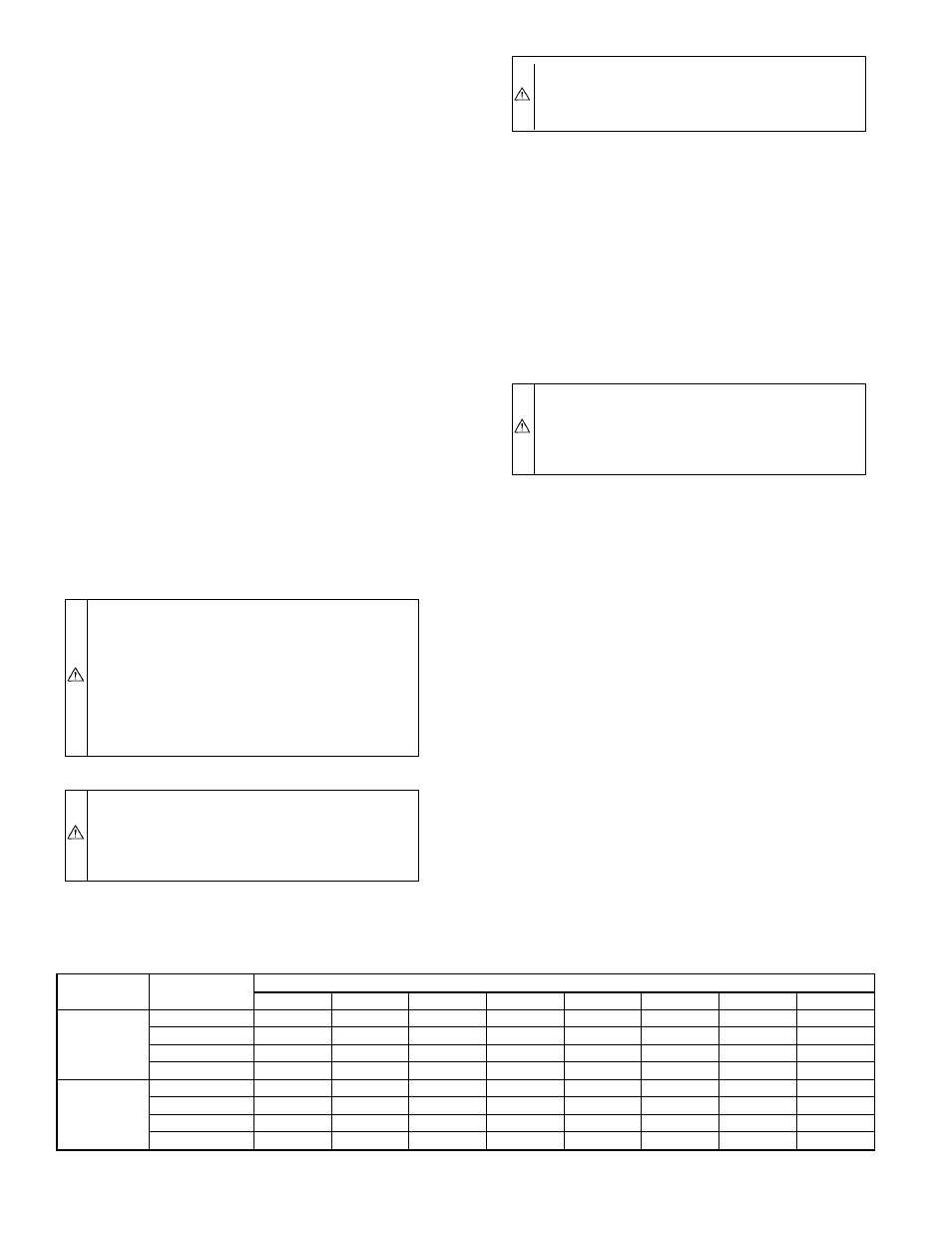

TABLE 7—AIRFLOW DATA (CFM)

UNIT

SIZE

BLOWER

SPEED

EXTERNAL STATIC PRESSURE IN. WC

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

036105

High

1425

1350

1305

1250

1170

1030

925

805

Med-High

1130

1045

1000

950

885

820

745

670

Med-Low

840

810

770

740

685

635

580

500

Low

725

730

740

745

730

715

690

665

060120

High

2080

2041

1965

1864

1702

1576

1474

1336

Med-High

1892

1859

1770

1675

1550

1449

1330

1217

Med-Low

1556

1475

1394

1318

1211

1134

1051

938

Low

1221

1164

1081

998

926

855

782

653

NOTES: 1. Airflow values in cubic ft per minute (CFM) rounded to nearest 5 CFM.

2. Data taken with filters in place.

—10—