Programming the brewer (cont.), Funnel detect ? no done yes – Bunn Dual TF DBC User Manual

Page 38

Page 38

PROGRAMMING THE BREWER (cont.)

EXIT TO

NEXT FUNCTION

SCREEN

EXIT TO

NEXT FUNCTION

SCREEN

PRESS AND RELEASE

® SYMBOL

PRESS AND RELEASE

® SYMBOL

NEXT COMPONENT

TO BE TESTED

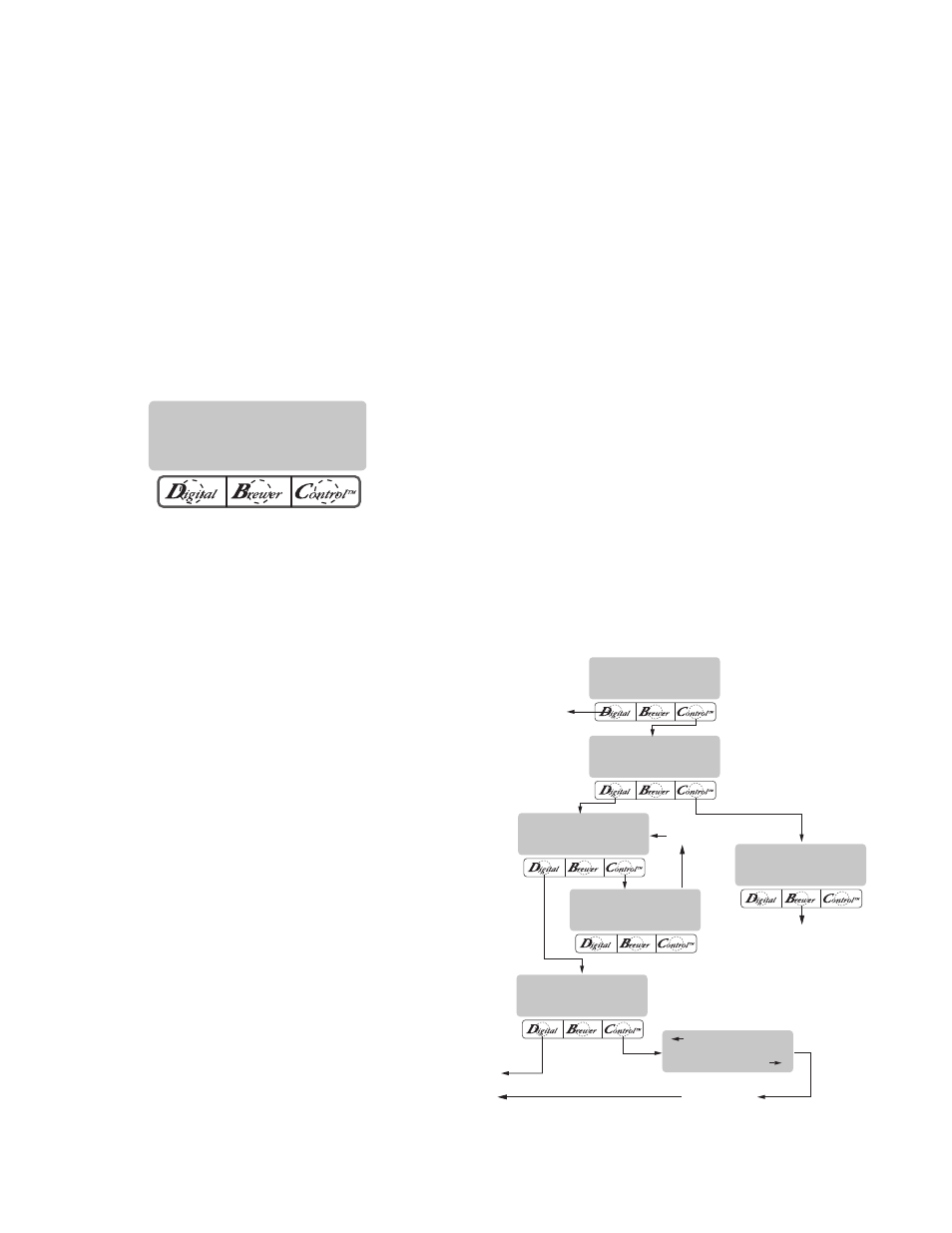

TEST OUTPUTS?

NO YES

TEST SWITCHES?

NO YES

LEFT BREW VALVE

ON NEXT OFF

125.0 KHZ. 4

4 125.0 KHZ.

NOTHING PRESSED

TEST FREQUENCY?

NO YES

SERVICE TOOLS?

NO YES

P2610

5. When fi

nished, press NEXT to advance counter

screens until the display reads BREW COUN-

TERS. Press and release NO to advance to the

next function screen, or press and release either

ON/OFF switch on the front switch panel to exit

the BREW COUNTERS function and return to the

MAIN SCREEN.

FUNNEL DETECT (optional)

This function allows the operator to prevent the

start of a brew cycle if a Smart Funnel is not positioned

correctly in the funnel rails.

Procedure to set funnel detect:

1. Press and hold the upper right hidden switch until

display reads UNITS. Release the switch. Continue

to press and release switch until display reads

FUNNEL DETECT.

2. NO or YES should be fl ashing to indicate the cur-

rent setting.

4. Select

YES to prevent brewing if a Smart Funnel is

not correctly situated in the rails. If this function

is activated and a brew cycle is attempted with the

funnel not properly situated, the display will read,

FUNNEL NOT IN PLACE, until one is in place.

5. Select

NO to allow brewing without a Smart Fun-

nel in place. This is selected when brewing with a

funnel other than a Smart Funnel (a regular brew

funnel).

6. When fi nished, press and release DONE. This will

retain the changes, exit this function screen and

advance to the next. Another alternative is to press

either ON/OFF switch located on the front switch

panel to exit the FUNNEL DETECT and return to

the MAIN SCREEN.

P2721

FUNNEL DETECT ?

NO

DONE

YES

BREW COUNTERS (cont.)

SERVICE TOOLS

This function allows the testing of individual com-

ponents and the ability to check switches for proper

function. This function also tests the Soft Heat

®

server's

status on the brewer (in place or removed), and the

funnel sensor coil's frequency (diagnostic tool for

troubleshooting purposes only).

Testing individual components (outputs):

This will allow the operator to test the operation

of individual components and outputs of the brewer.

The components that can be individually tested are as

follows:

Left Brew Valve

Left Bypass Valve

Left Funnel Lock

Left Server

Right Brew Valve

Right Bypass Valve

Right Funnel Lock

Right Server

Refi ll Valve

Tank Heaters

Heater Contactor

35058.1 071205