Bryant DURAPAC PLUS SERIES 542J User Manual

Page 31

—

31

—

E. DCV Minimum and Maximum Position

To check the DCV minimum and maximum position:

1. Make sure EconoMi$erIV preparation procedure has

been performed.

2. Connect a 9-v battery to AQ (positive node) and AQ1

(negative node). The DCV LED should turn on. The

actuator should drive to between 90 and 95% open.

3. Turn the DCV Maximum Position potentiometer to

midpoint. The actuator should drive to between 20

and 80% open.

4. Turn the DCV Maximum Position potentiometer to

fully CCW. The actuator should drive fully closed.

5. Turn the Minimum Position potentiometer to mid-

point. The actuator should drive to between 20 and

80% open.

6. Turn the Minimum Position Potentiometer fully CW.

The actuator should drive fully open.

7. Remove the jumper from TR and N. The actuator

should drive fully closed.

8. Return EconoMi$erIV settings and wiring to normal

after completing troubleshooting.

F. Supply-Air Input

To check supply-air input:

1. Make sure EconoMi$erIV preparation procedure has

been performed.

2. Set the Enthalpy potentiometer to A. The Free Cool

LED turns on. The actuator should drive to between

20 and 80% open.

3. Remove the 5.6 kilo-ohm resistor and jumper T to T1.

The actuator should drive fully open.

4. Remove the jumper across T and T1. The actuator

should drive fully closed.

5. Return EconoMi$erIV settings and wiring to normal

after completing troubleshooting.

G. EconoMi$erIV Troubleshooting Completion

This procedure is used to return the EconoMi$erIV to opera-

tion. No troubleshooting or testing is done by performing the

following procedure.

1. Disconnect power at TR and TR1.

2. Set enthalpy potentiometer to previous setting.

3. Set DCV maximum position potentiometer to previ-

ous setting.

4. Set minimum position, DCV set point, and exhaust

potentiometers to previous settings.

5. Remove 620-ohm resistor from terminals S

R

and +.

6. Remove 1.2 kilo-ohm checkout resistor from terminals

S

O

and +. If used, reconnect sensor from terminals S

O

and +.

7. Remove jumper from TR to N.

8. Remove jumper from TR to 1.

9. Remove 5.6 kilo-ohm resistor from T and T1. Recon-

nect wires at T and T1.

10. Remove jumper from P to P1. Reconnect device at P

and P1.

11. Apply power (24 vac) to terminals TR and TR1.

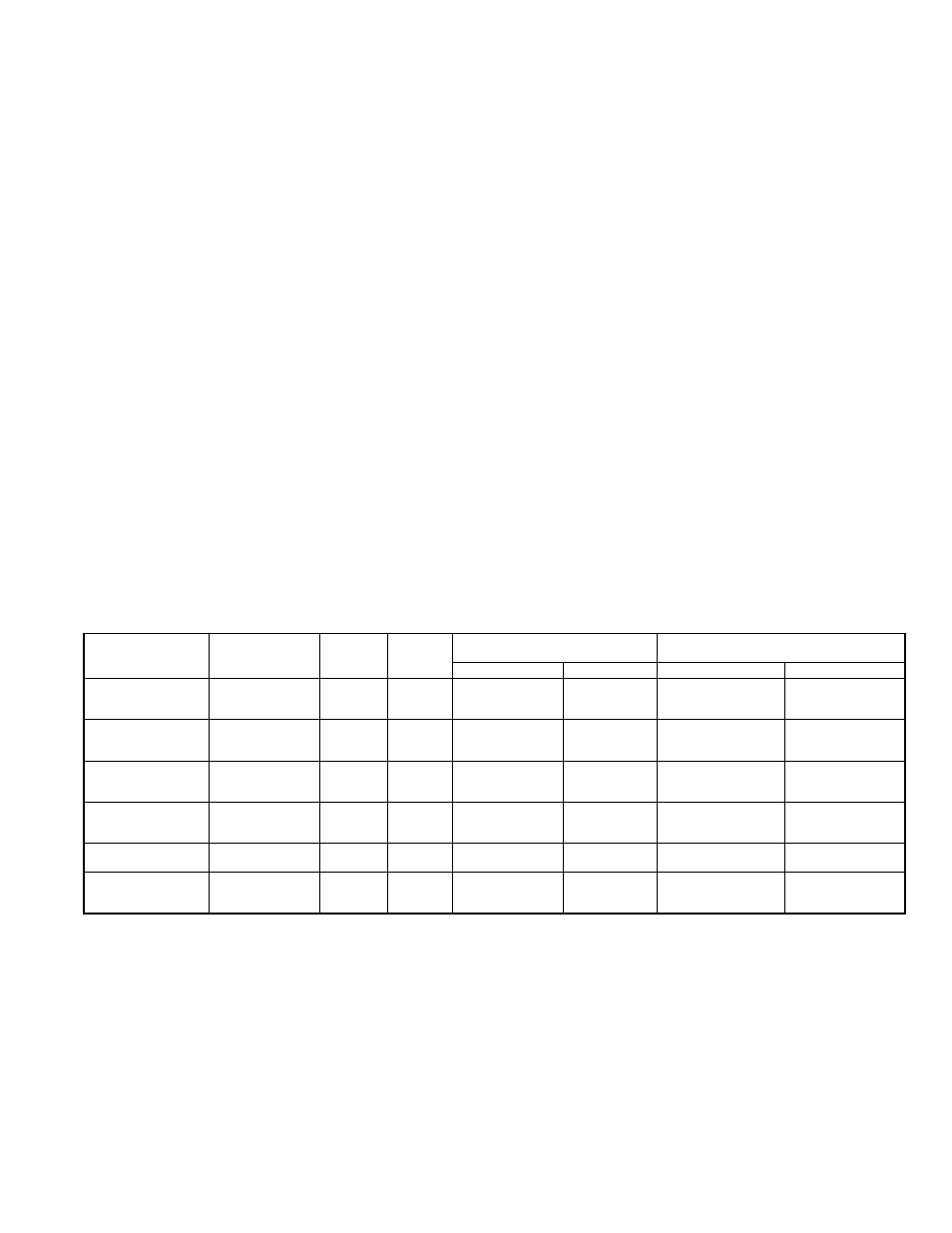

Table 15 — Check Valve Functions

CHECK VALVE

IDENTIFICATION

(See Fig. 42 and 43)

LOCATION

COOLING

CYCLE

HEATING

CYCLE

COOLING CYCLE

CHECK VALVE STUCK

HEATING CYCLE

CHECK VALVE STUCK

Open

Closed

Open

Closed

A

Outdoor coil;

Header

Closed

Open

Lose circuiting in

outdoor coil. Acts

like low charge.

Normal

Normal

Bottom 3 circuits

restricted

B

Outdoor coil;

Liquid line feeding

fixed orifice

Open

Closed

Normal

Lose some

capacity

Restricted outdoor

fixed orifice

Normal

C

Outdoor coil;

Liquid line leaving

coil

Closed

Open

Restricted

liquid line

Normal

Normal

Flooding outdoor

coil and compressor

D

Indoor coil; Liquid

line feeding fixed

orifice

Open

Closed

Normal

Restricted

indoor

fixed orifice

Lose some capacity

Normal

E

Indoor coil; Liquid

line leaving coil

Closed

Open

Bypasses coil and

floods compressor

Normal

Normal

Restricted

liquid line

F

Indoor coil;

Header

Open

Closed

Normal

Bottom circuits

of indoor coil

inactive

Lose indoor coil

circuiting — symptom

of low charge

Normal