Bryant 548J*14D User Manual

Page 15

15

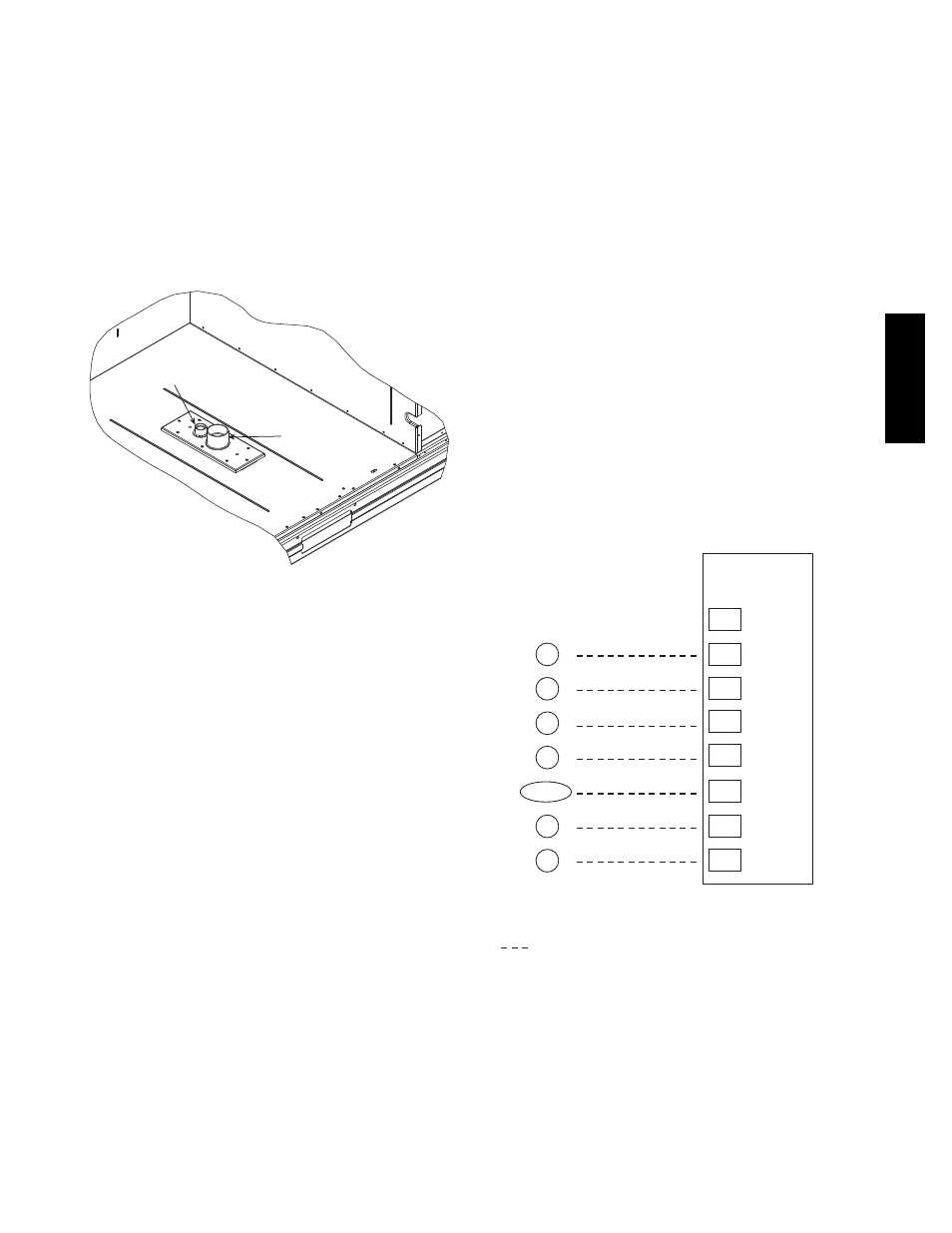

Factory--Option Thru--Base Connections —

This service connection kit consists of a

1

/

2

--in electrical

bulkhead connector and a 1

1

/

2

--in electrical bulkhead

connector, all factory--installed to the basepan cover plate.

Remove the cover plate from the shipping bracket and

attach to basepan with 8 screws provided. The

1

/

2

--in

bulkhead connector enables the low--voltage control wires

to pass through the basepan. The 1

1

/

2

--in electrical

bulkhead connector allows the high--voltage power wires

to pass through the basepan. See Fig. 26.

Check tightness of connector lock nuts before connecting

electrical conduits.

LOW VOLTAGE

CONDUIT

CONNECTOR

HIGH VOLTAGE

CONDUIT

CONNECTOR

C10017

Fig. 26 -- Thru--Base Connection Fittings

Field--supplied and field--installed liquidtight conduit

connectors and conduit may be attached to the connectors

on the basepan. Pull correctly rated high voltage and low

voltage wires through appropriate conduits. Connect the

power conduit to the internal disconnect (if unit is so

equipped) or to the external disconnect (through unit side

panel). Remove one of the two knockouts located on the

bottom left side of the unit control box. Use this hole for

the control conduit.

Units without Thru--Base Connections —

1. Install power wiring conduit through side panel open-

ings. Install conduit between disconnect and control

box.

2. Install power lines to terminal connections as shown

in Fig. 22.

Field Control Wiring —

The 548J*14D unit requires an external temperature

control device. This device can be a thermostat emulation

device provided as part of a third--party Building

Management System.

Thermostat —

Install

a

Bryant--approved

accessory

2

stage

Cooling/Heating thermostat according to installation

instructions included with the accessory. The 548J*14D

models do not require a thermostat with an O function to

control the reversing valve operation. If using an

electronic thermostat, configure it for “non--heat pump”

operation. Locate the thermostat accessory on a solid wall

in the conditioned space to sense average temperature in

accordance with the thermostat installation instructions.

If the thermostat contains a logic circuit requiring 24--v

power, use a thermostat cable or equivalent single leads of

different colors with minimum of seven leads. If the

thermostat does not require a 24--v source (no “C”

connection required), use a thermostat cable or equivalent

with minimum of six leads. Check the thermostat

installation instructions for additional features which

might require additional conductors in the cable.

For wire runs up to 50 ft. (15 m), use no. 18 AWG

(American Wire Gage) insulated wire (35_C minimum).

For 50 to 75 ft. (15 to 23 m), use no. 16 AWG insulated

wire (35_C minimum). For over 75 ft. (23 m), use no. 14

AWG insulated wire (35_C minimum). All wire sizes

larger than no. 18 AWG cannot be directly connected to

the thermostat and will require a junction box and splice

at the thermostat.

X

C

G

W2

C

W2

G

W1

O/B/Y2

Y2

R

W1

R

Y1

Y1

T

H

E

R

M

O

S

T

A

T

(Note 1)

(Note 2)

Note 1: Typical multi-function marking. Follow manufacturer’s configuration

instructions to select Y2. Do not configure for O output.

Note 2: W2 connection not required on units without electric heating.

Field Wiring

Central

Terminal

Board

Typical

Thermostat

Connections

C09012

Fig. 27 -- Typical Low--Voltage Control Connections

548J

*14D