Warning, Step 10 — make electrical connections – Bryant 548J*14D User Manual

Page 11

11

The piping for the condensate drain and external trap can

be completed after the unit is in place. See Fig. 15.

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4” (102) trap is recommended

.

MINIMUM PITCH

1” (25mm) PER

10’ (3m) OF LINE

BASE RAIL

OPEN

VENT

TO ROOF

DRAIN

DRAIN PLUG

ROOF

CURB

SEE NOTE

2˝ (51) MIN

C08022

Fig. 15 -- Condensate Drain Piping Details

All units must have an external trap for condensate

drainage. Install a trap at least 4-in. (102 mm) deep and

protect against freeze-up. If drain line is installed

downstream from the external trap, pitch the line away

from the unit at 1-in. per 10 ft (25 mm in 3 m) of run. Do

not use a pipe size smaller than the unit connection

(

3

/

4

-in.).

Step 10 — Make Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit

cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of

personal injury if an electrical fault should occur. This

ground may consist of electrical wire connected to

unit ground lug in control compartment, or conduit

approved for electrical ground when installed in

accordance with NEC (National Electrical Code);

ANSI/NFPA 70, latest edition (in Canada, Canadian

Electrical

Code

CSA

[Canadian

Standards

Association] C22.1), and local electrical codes.

!

WARNING

NOTE: Check all factory and field electrical connections

for tightness. Field--supplied wiring shall conform with

the limitations of 63_F (33_C) rise.

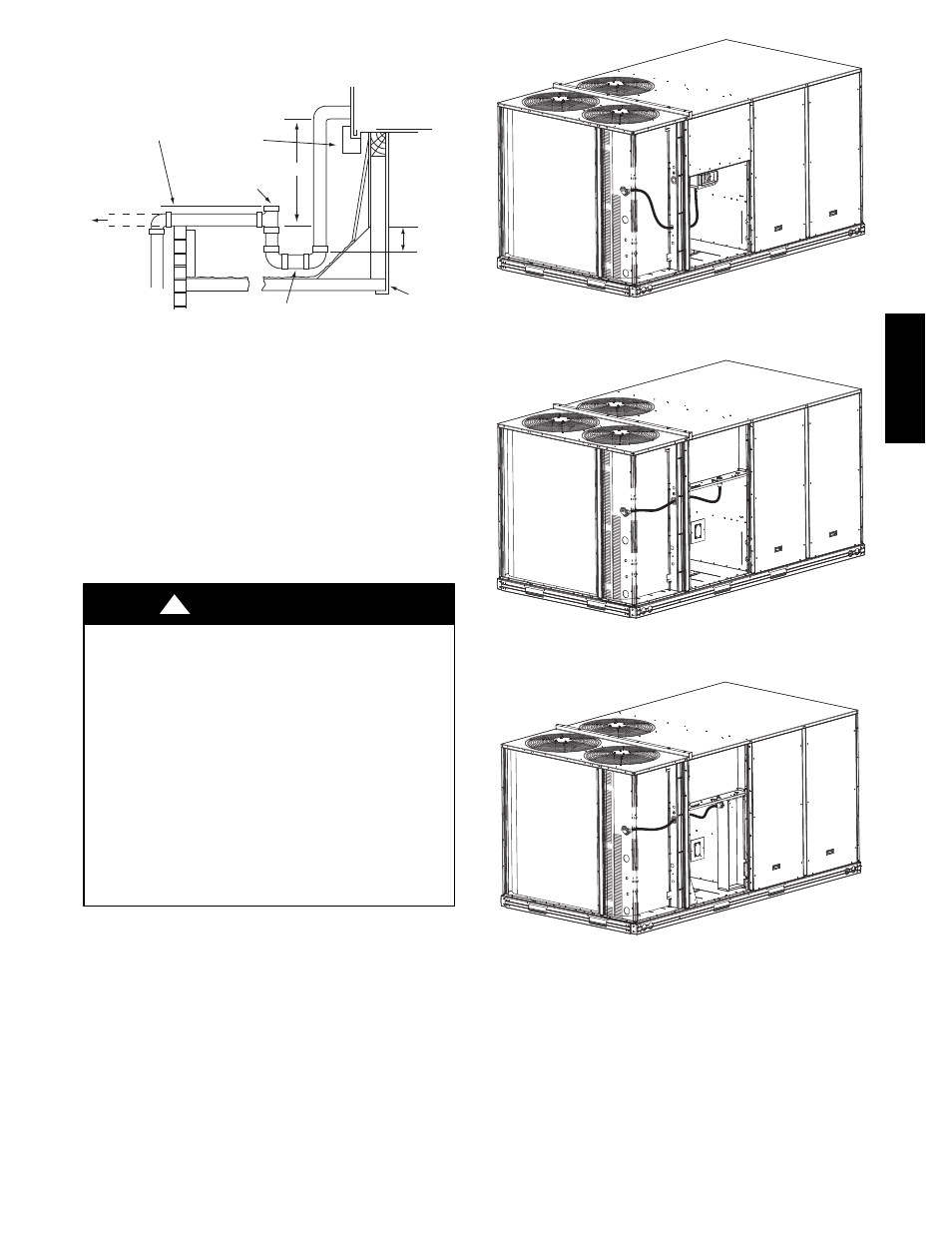

Field Power Supply —

For those units without through--the--curb power, conduit

must be used to route the main power from the condenser

end of the unit to either the factory option disconnect, the

bottom of the control box or the single point box

accessory. 1” conduit is provided behind the access panel

located under the control box. For those units that require

conduit larger than 1”, it must be field supplied. Figures

16, 17 and 18 show the various wire routings.

C10010

Fig. 16 -- Conduit into Factory Option Disconnect

C10011

Fig. 17 -- Conduit into Control Box

C10012

Fig. 18 -- Conduit into Single Point Box

If the field disconnect is larger than 100A, it must be

attached to the unit using accessory CRDISBKT001A00

(see Fig. 19). Follow the instructions provided with this

accessory. For smaller field disconnects, be sure to use

1

/

2

” screws to mount the disconnect directly to the end

panel (see Fig. 20). In either case, set the disconnect

vertical location on the unit so that a 90_ fitting can be

used to connect the conduit to the disconnect.

548J

*14D