Bryant 373LAV User Manual

Page 9

IX.

GAS PIPING

Gas piping must be installed in accordance with national and local

codes. Refer to the current edition of the NFGC.

Canadian installations must be installed in accordance with NSC-

NGPIC and all authorities having jurisdiction.

Refer to Table 5 for recommended gas pipe sizing. Risers should

be used to connect to the furnace and to the meter.

CAUTION:

If a flexible connector is required or al-

lowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and extend a

minimum of 2 in. outside the furnace casing.

WARNING:

Use the proper length of pipes to avoid

stress on the gas control manifold. Failure to follow this

warning could result in a gas leak, causing fire, explosion,

personal injury, or death.

CAUTION:

Connect the gas pipe to the furnace using a

backup wrench to avoid damaging gas controls.

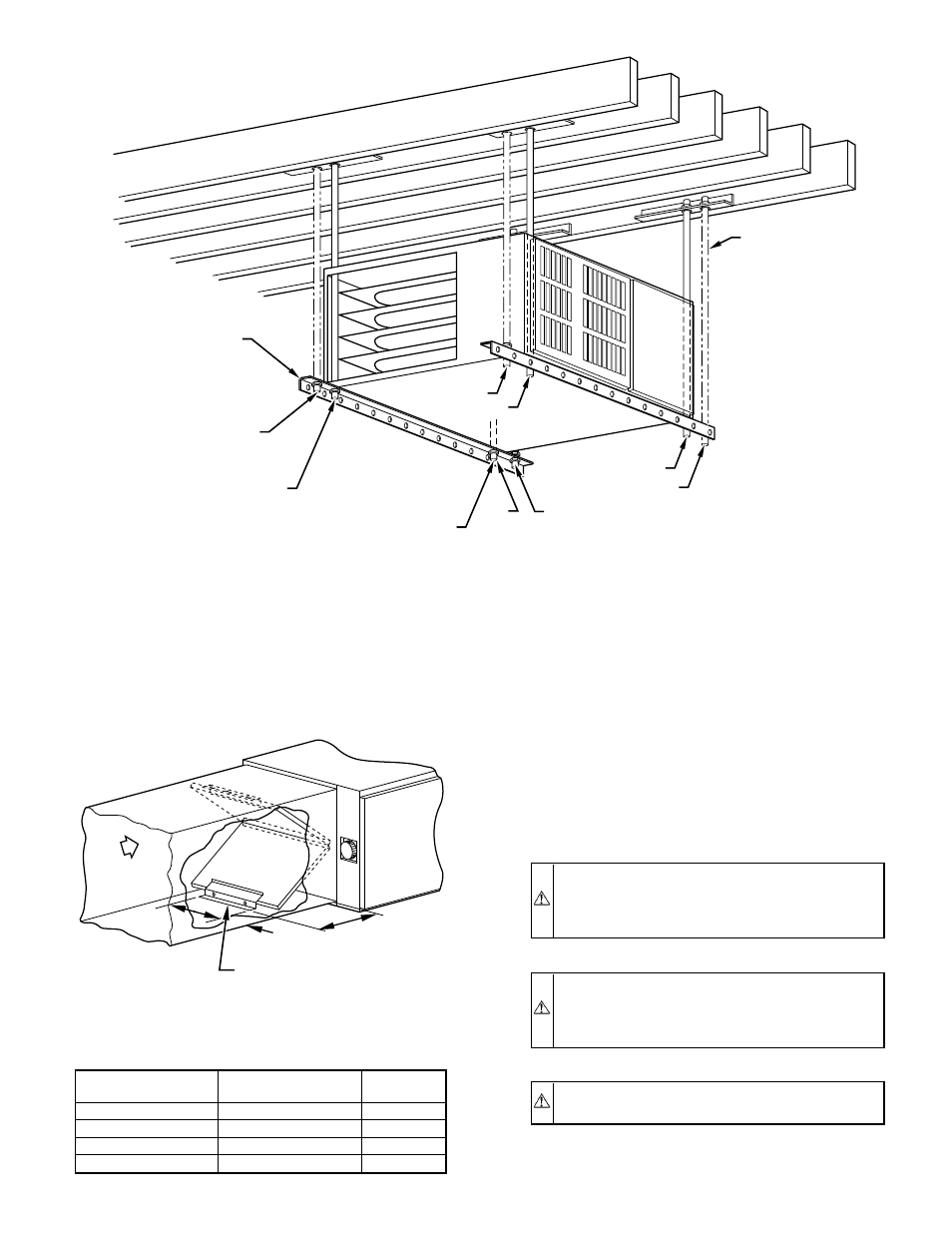

Fig. 10—Horizontal Crawlspace Installation on Hanger Rods

A96633

NOTES:

ANGLE

IRON OR

EQUIVALENT

ROD LOCATION

USING DIMPLE

LOCATORS

(SEE DIMENSIONAL

DWG FOR

LOCATIONS)

3

⁄

8

-IN. ROD

1. A 1 In. clearance minimum between top of

furnace and combustible material.

2. The entire length of furnace must be

supported when furnace is used in horizontal

position.

3

/

8

-IN. HEX NUT

& WASHER (4)

REQD PER ROD

(A) PREFERRED ROD LOCATION

(B) ALTERNATE ROD LOCATION

(A)

(B)

(A)

(B)

(B)

(A)

(A)

(B)

TABLE 4—FILTER RETAINER (IN.)

FURNACE

CASING WIDTH

FILTER SIZE

AND QUANTITY

D

14-3/16

(2) 14 X 20 X 1

14-3/8

17-1/2

(2) 14 X 20 X 1

13-3/8

21

(2) 16 X 20 X 1

11-5/8

24-1/2

(2) 16 X 20 X 1

10-1/4

Fig. 11—Horizontal Filter Arrangement

A82173

FIELD-SUPPLIED

FILTER RETAINERS

AIRFLOW

D

12

″

4

″

—9—