Bryant 373LAV User Manual

Page 7

A.

Construct a Working Platform

Construct working platform on location where all required

furnace clearances are met. (See Fig. 2 and 8.)

B.

Install Furnace

1. Position furnace in desired location.

2. Connect gas supply pipe. See Fig. 8 for typical piping entry.

3. Install field-supplied filter retainers as indicated in Fig. 11

and Table 4 before connecting return-air duct to furnace.

4. Connect supply- and return-air ducts.

5. Install 24- X 24-in. sheet metal shield on platform in front

of louvered control panel as shown in Fig. 8.

VII.

HORIZONTAL CRAWLSPACE INSTALLATION

The furnace can be installed horizontally with either the LH or RH

side up. In a crawlspace, the furnace can either be installed on

suitable blocks or pad (See Fig. 9.) or hung from the floor joist.

(See Fig. 10). The furnace can be suspended from each corner by

hanger bolts (4 each 3/8-in. all-thread rod) cut to desired length,

1 X 3/8-in. flat washer, 3/8-in. lockwasher, and 3/8-in. nut.

Dimples are provided for hole locations. (See Fig. 1.)

Since horizontal crawlspace installation is very similar to the attic

installation, refer to Section VI. The installation of a sheet metal

shield in front of the louvered control panel is covered in Section

VI. For a crawlspace installation, this same sheet metal shield must

be installed above the louvered control panel. Extend the sheet

metal shield over the furnace top far enough to cover the gas pipe

entry hole.

VIII.

FILTER ARRANGEMENT

WARNING:

Never operate unit without a filter or with

filter access door removed. Failure to follow this warning

could result in fire, personal injury, or death.

The 2 factory-supplied filters are shipped in the blower compart-

ment. After the return-air duct has been connected to the furnace,

install the filters in a V-formation inside the return-air plenum. See

Fig. 11 and Table 4 for horizontal applications. Horizontal filter

retainers must be field supplied. See Fig. 12 for downflow

applications.

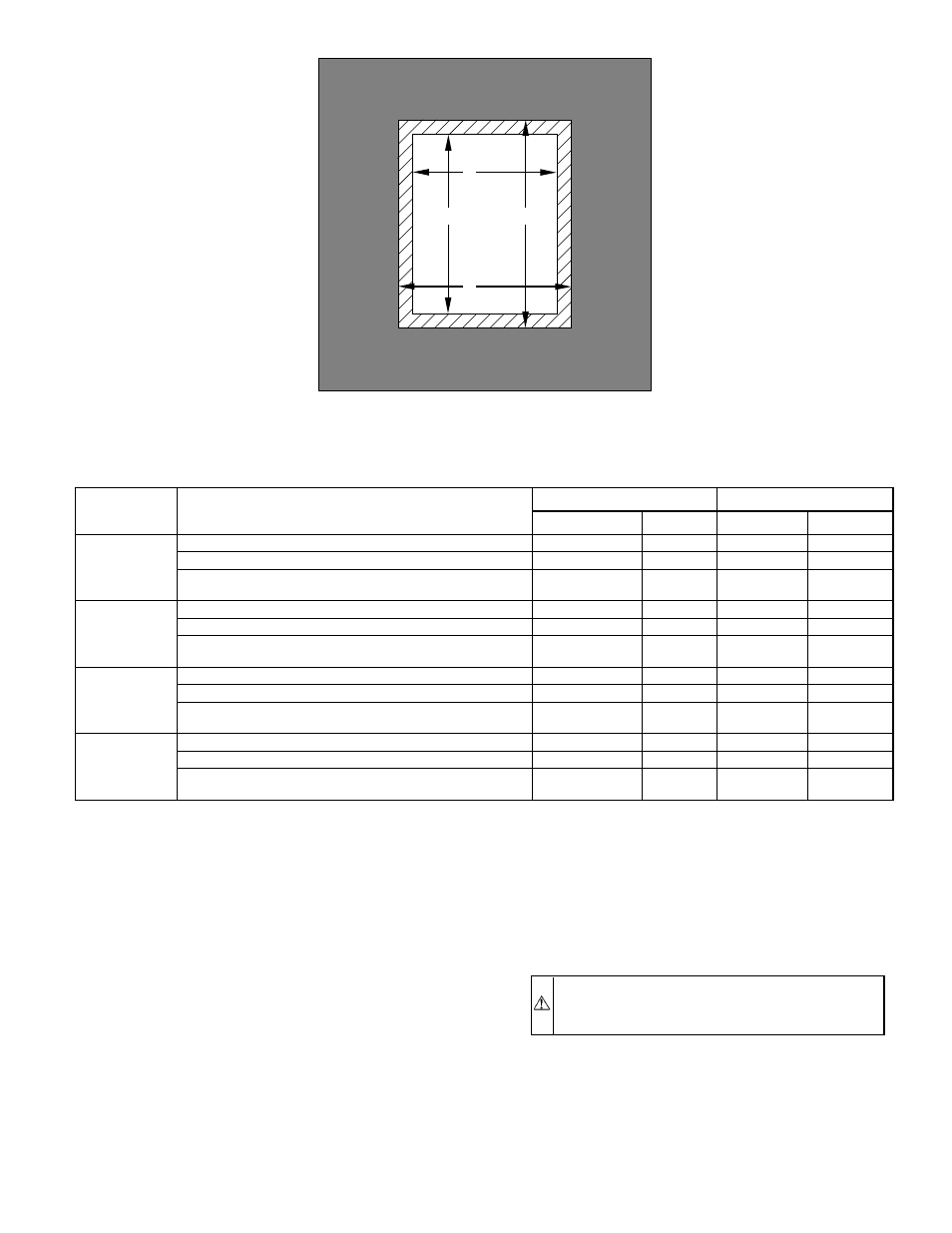

TABLE 3—OPENING DIMENSIONS (IN.)

FURNACE

CASING

WIDTH

APPLICATION

PLENUM OPENING

FLOOR OPENING

A

B

C

D

14-3/16

Non-Combustible Flooring

12-11/16

19

13-3/8

19-5/8

Combustible Flooring Using KGASB Subbase

11-13/16

19

13-7/16

20-3/8

Combustible Flooring with CD5 or CK5 Coil Assembly or

KCAKC Coil Box

12-5/16

19

13-5/16

20

17-1/2

Non-Combustible Flooring

16

19

16-5/8

19-5/8

Combustible Flooring Using KGASB Subbase

15-1/8

19

16-3/4

20-3/8

Combustible Flooring with CD5 or CK5 Coil Assembly or

KCAKC Coil Box

15-1/2

19

16-1/2

20

21

Non-Combustible Flooring

19-1/2

19

20-1/8

19-5/8

Combustible Flooring Using KGASB Subbase

18-5/8

19

20-1/4

20-3/8

Combustible Flooring with CD5 or CK5 Coil Assembly or

KCAKC Coil Box

19

19

20

20

24-1/2

Non-Combustible Flooring

23

19

23-5/8

19-5/8

Combustible Flooring Using KGASB Subbase

22-1/8

19

23-3/4

20-3/8

Combustible Flooring with CD5 or CK5 Coil Assembly or

KCAKC Coil Box

22-1/2

19

23-1/2

20

Fig. 5—Floor and Plenum Opening Dimensions

A96283

PLENUM

OPENING

C

A

B

D

FLOOR

OPENING

—7—

→