Vollrath M202B Water Cooled User Manual

Page 17

Owner’s Manual #513666 Rev.1

11

M202B Model Machines

3.3 SANITIZING

Sanitizing must be done after the machine is cleaned and

just before the hopper is fi lled with mix. Sanitizing the night

before is not effective. However, you should always clean

the machine and parts after each use.

THE UNITED STATES DEPARTMENT OF AGRI-

CULTURE AND THE FOOD AND DRUG ADMIN-

ISTRATION REQUIRE THAT ALL CLEANING AND

SANITIZING SOLUTIONS USED WITH FOOD

PROCESSING EQUIPMENT BE CERTIFIED FOR

THIS USE.

When sanitizing the machine, refer to local sanitary regu-

lations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions to

provide a 100 parts per million strength solution. Mix sani-

tizer in quantities of no less than 2 gallons (7.5 liters) of

90° to 110°F (32° to 43°C) water. Allow sanitizer to contact

the surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the manufacturer’s

instructions.

In general, sanitizing may be conducted as follows:

A.

Prepare Stera-Sheen Green Label Sanitizer

or equivalent according to manufacturer’s

instructions to provide a 100ppm strength solution.

Mix the sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32° to 43°C) water. Any

sanitizer must be used only in accordance with

the manufacturer’s instructions.

B.

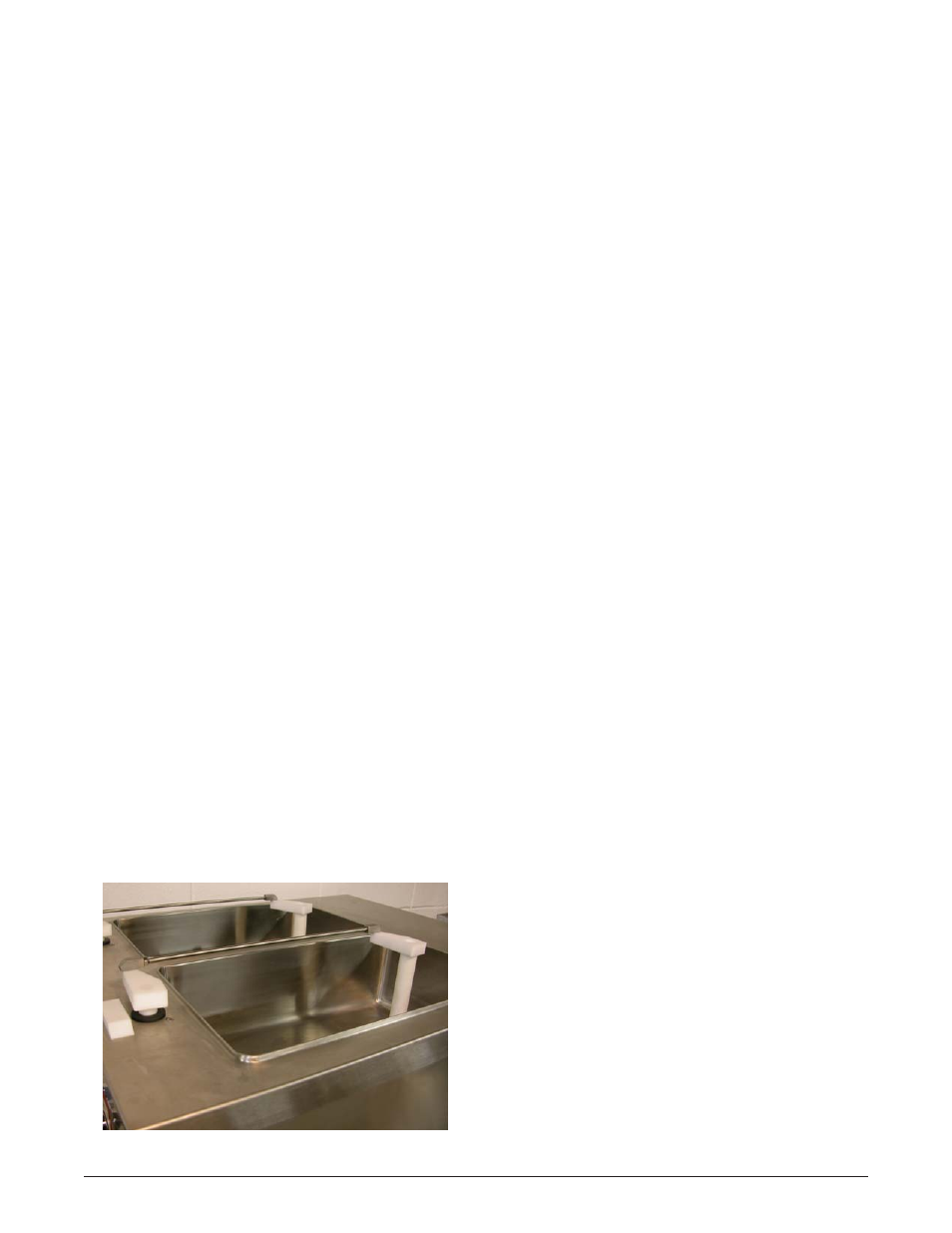

Place the tapered end of the fl ow valve into the

hopper drain hole with the arm pointing towards

the left. Connect the fl ow control rod to the fl ow

valve and the fl ow valve arm (Fig. 3-3).

C.

Make sure the fl ow control valve is shut by turning

the control knob counterclockwise to the 12:00

position.

D.

Place a bucket under the slide.

E.

Pour the sanitizer into the hopper.

NOTE

A small amount of sanitizer may drain into the

bucket with the fl ow control shut and may seep out

of the rear seal.

F.

Place the Freezing Cylinder OFF-ON switch in

the ON position and press the PURGE/CLEAN

button. The display will read PURGE.

G.

Press and hold the PURGE/CLEAN button for 3

seconds. The display will read CLEAN and a 10

minute timer will start.

H. Turn

the

fl ow control knob fully open (clockwise)

to drain the sanitizer from the freezing cylinder.

I.

Clean sides of hopper, fl ow valve and underside

of hopper cover using a sanitized soft bristle brush

dipped in the sanitizing solution.

J.

When the sanitizer has drained from the hopper,

press and hold the PURGE/CLEAN button for

3 seconds to stop the auger. Allow the freezing

cylinder to drain completely.

K. Shut

off

the

fl ow control valve by turning the

fl ow control knob counterclockwise to the 12:00

position.

3.4 FREEZE DOWN AND OPERATION

This section covers the recommended operating proce-

dures to be followed for the safe operation of the machine.

A.

Sanitize just prior to use.

NOTE

Make sure the fl ow control assembly is in place

before adding mix and that the fl ow control knob is

set to the 12:00 position.

B.

Fill the hopper with pre-chilled (40°F or 4°C) mix.

C.

Place the FREEZING CYLINDER switch in the

ON position. The display will read STANDBY

MODE.

D.

Press the PUSH TO FREEZE button. The display

will read CUSTARD and a bar on the second line

will start to fi ll. On the right cylinder the product

type can be changed by moving the Product

Selector switch to the Lemon Ice position.

NOTE

The Product Selector switch can be changed until

the READY message is displayed on the second

line.

E.

When the display reads CUSTARD READY, the

freezing cylinder is at the correct temperature

(Fig. 3-4).

F.

Open the front gate.

Figure 3-3 Flow Control Assembly