Vollrath SU412 User Manual

Page 20

14

E.

Place the mix pump switch in the ON position.

F.

Place a container under the spigot and open the

spigot to allow the mix to fl ush out about 8 ounces

(0.23 liters) of sanitizing solution and liquid mix.

Close the spigot.

G.

Open the air bleed valve on the front door by

pressing and holding. Hold the valve open until

the mix level in the freezing cylinder is 1/2” from

the air bleed valve.

H.

Place the Freezing Cylinder OFF/ON switch in

the ON position. Make sure the blender power

plug is connected to the machine and place the

Blender Power Off/On switch in the ON position.

WARNING

Hazardous Moving Parts

Blender shaft and agitator can grab and cause

injury. Do not operate blender without protective

shield or swing splash shield.

I.

Press the PUSH TO FREEZE button.

NOTE

After the drive motor starts, there is a 3-second

delay before the compressor starts.

J.

When the product is at 75% consistency, the

display will read “SERVE”.

K.

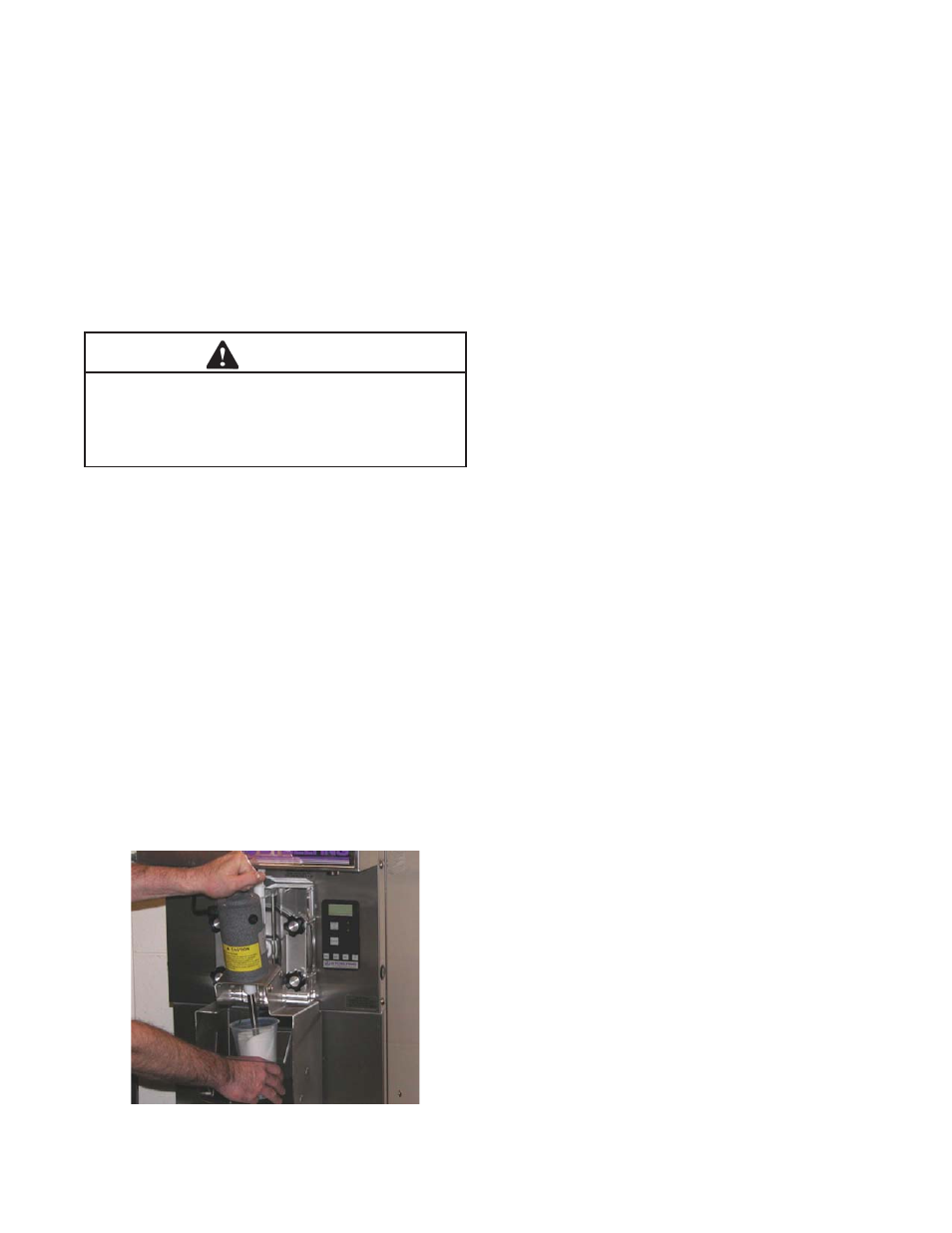

For normal dispensing, move the spigot handle

fully open (Fig. 3-9).

L.

On SU412 model, push the spigot handle to the

right to activate the blender. The blender will

operate during or after dispensing product.

M.

Do not operate the machine when the MIX LOW

message is displayed. Refi ll the mix container

immediately.

NOTE

The machine has a standby and sleep mode. After

a preset number of freezing cycles, it will enter the

standby mode (followed by sleep mode) and remain

there until someone draws product or presses the

PUSH TO FREEZE button. In the sleep mode, the

machine will keep the product below 45°F (7.2°C).

Sleep modes do not take the place of cleaning

and sanitizing. Federal, State, and local regulatory

agencies determine frequency of cleaning and

sanitizing.

3.12 MIX INFORMATION

Mix can vary considerably from one manufacturer to

another. Differences in the amount of butterfat content

and quantity and quality of other ingredients have a

direct bearing on the fi nished frozen product. A change

in machine performance that cannot be explained by a

technical problem may be related to the mix.

Proper product serving temperature varies from one

manufacturer’s mix to another. Mixes should provide a

satisfactory product in the 20°F to 24°F range. Diet and

low-carb mixes typically freeze to proper consistency at

higher temperatures.

When checking the temperature, stir the thermometer in

the frozen product to get an accurate reading.

Old mix, or mix that has been stored at too high a tempera-

ture, can result in a fi nished product that is unsatisfactory.

To retard bacteria growth in dairy based mixes, the best

storage temperature range is between 33° to 38°F (0.5°

to 3.3° C).

3.13 OPERATION OF MIX PUMP

The mix pump switch is located at the front of the machine.

When a pump switch is placed in the ON position, the

mix pump motor will start pumping mix into the freezing

cylinder. When the set pressure is reached, the mix pump

will shut off automatically. When the switch is placed in

the OFF position, the mix pump will not operate.

NOTE

The mix pump motor is equipped with an internal

overload that will “trip”, disabling the pump when

the motor is overloaded. Consult the trouble shoot-

ing section for corrective information. The internal

overload will automatically reset after cooling. If

the condition continues, contact a qualifi ed service

person.

Figure 3-9 Dispensing Product