Vollrath SU412 User Manual

Page 16

10

3.8 ASSEMBLING MACHINE

To assemble the machine parts, refer to the following steps:

NOTICE

Petrol-Gel sanitary lubricant or equivalent must be

used when lubrication of machine parts is specifi ed.

NOTICE

The United States Department of Agriculture and

the Food and Drug Administration require that lubri-

cants used on food processing equipment be certi-

fi ed for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

A.

Assemble all o-rings onto parts dry, without

lubrication. Then apply a thin fi lm of sanitary

lubrication to exposed surfaces of the o-rings.

B.

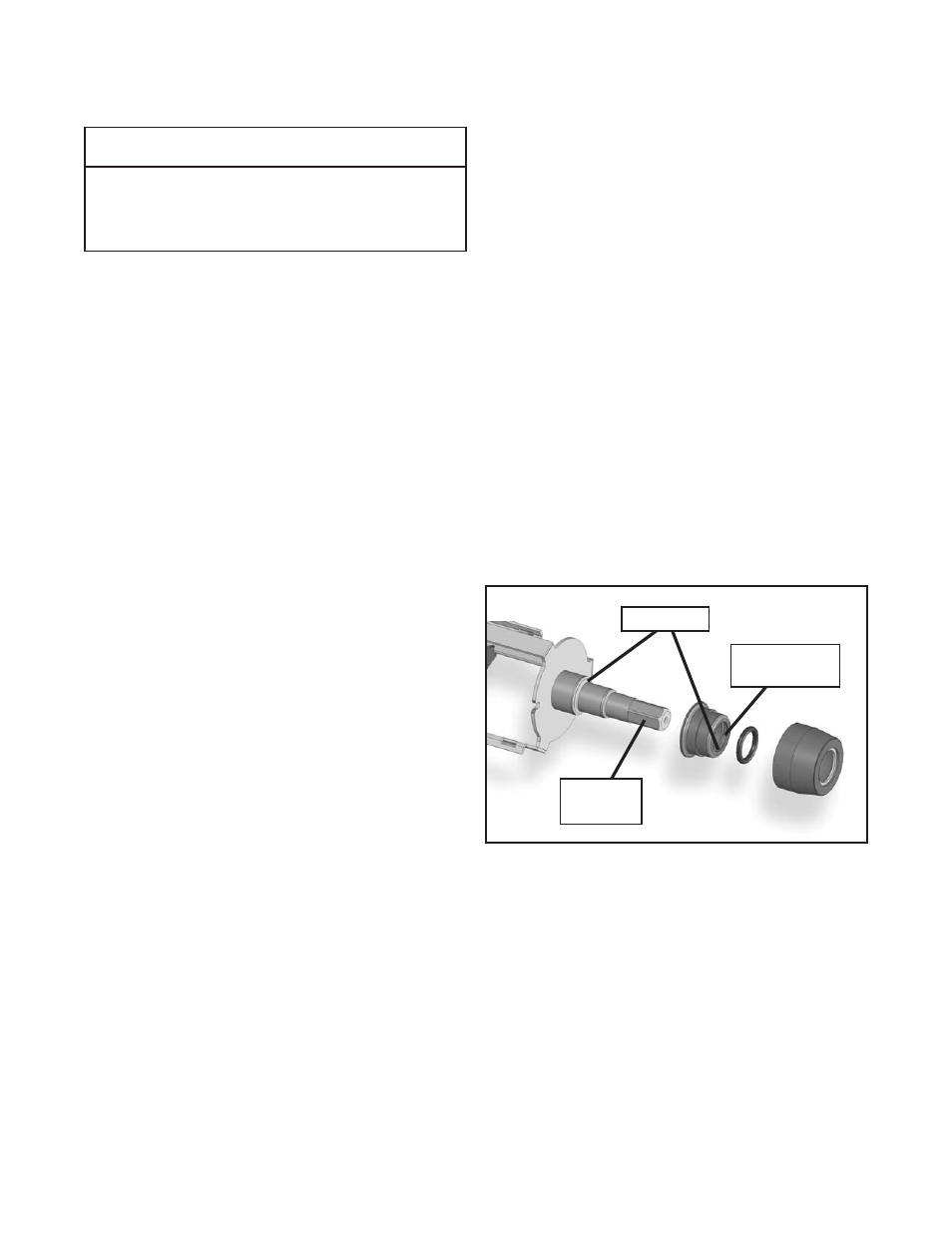

Lubricate the rear seal area on the auger shaft

with a thin layer of sanitary lubricant. Install the

rear seal o-ring. Lubricate the outside of the rear

seal o-ring with sanitary lubricant.

C.

Install the stainless steel rear seal adapter into

the rear seal dry (without lubricant). Lubricate the

inside surface of the rear seal adapter, including

the adapter o-ring, and install it onto the auger

shaft. DO NOT lubricate the outside of the rear

auger seal (Fig. 3-5).

D.

Lubricate the hex drive end of the auger with a

small amount of spline lubricant. A small container

of it is shipped with the machine.

E.

Install the two plastic scraper blades onto the

auger and insert into the freezing cylinder.

F.

Rotate the auger until it engages the drive shaft.

G.

Assemble the air bleed valve o-ring onto the air

bleed valve. Position the o-ring into the groove

close to the wide part. Apply a thin fi lm of sanitary

lubricant to the o-ring.

B.

Place all front door and auger parts in clean 90° to

110°F (32°C to 43°C) water and wash thoroughly

(four sink procedure only).

CAUTION

Blender motor can NOT be immersed in water or

sanitizer. Wash the motor and mounting bracket

with a mild detergent solution taking care not to

allow water into the motor bearings or seals.

C.

Place all parts in 90° to 110°F (32°C to 43°C) mild

detergent water and wash thoroughly.

D.

Rinse all parts with clean 90° to 110°F (32°C to

43°C) water.

E.

Sanitize all machine parts following procedures

outlined below.

3.6 SANITIZING MACHINE PARTS

A.

Use a sanitizer, mixed according to manufacturer’s

instructions, to provide a 100 parts per million

strength solution. Mix sanitizer in quantities of

no less than 2 gallons of 90° to 110°F (32°C to

43°C) water. Any sanitizer must be used only in

accordance with the manufacturer’s instructions.

B.

Place all parts in the sanitizing solution for 5

minutes, then remove and let air dry completely

before assembling in machine.

3.7 CLEANING THE MACHINE

The exterior should be kept clean at all times to preserve

the luster of the stainless steel. A high grade of stainless

steel has been used on the machine to ease cleanup. To

remove spilled or dried mix, wash the exterior with 90° to

110°F (32°C to 43°C) soapy water and wipe dry.

Do not use highly abrasive materials, as they will mar the

fi nish. A mild alkaline cleaner is recommended. Use a soft

cloth or sponge to apply the cleaner. For best results, wipe

with the grain of the steel.

A.

Clean the rear seal surface from inside of the

freezing cylinder.

B.

Using sanitizing solution and the large barrel

brush provided, sanitize the freezing cylinder by

dipping the brush in the sanitizing solution and

brushing the inside of the freezing cylinder.

C.

Remove the rear drip tray by pulling from the side

panel. Clean and replace the drip tray.

Figure 3-5 Rear Seal Assembly

Spline

Lubricant

Petrol-Gel

Place O-Ring

Inside Insert