Vollrath O231 Water Cooled User Manual

Page 12

6

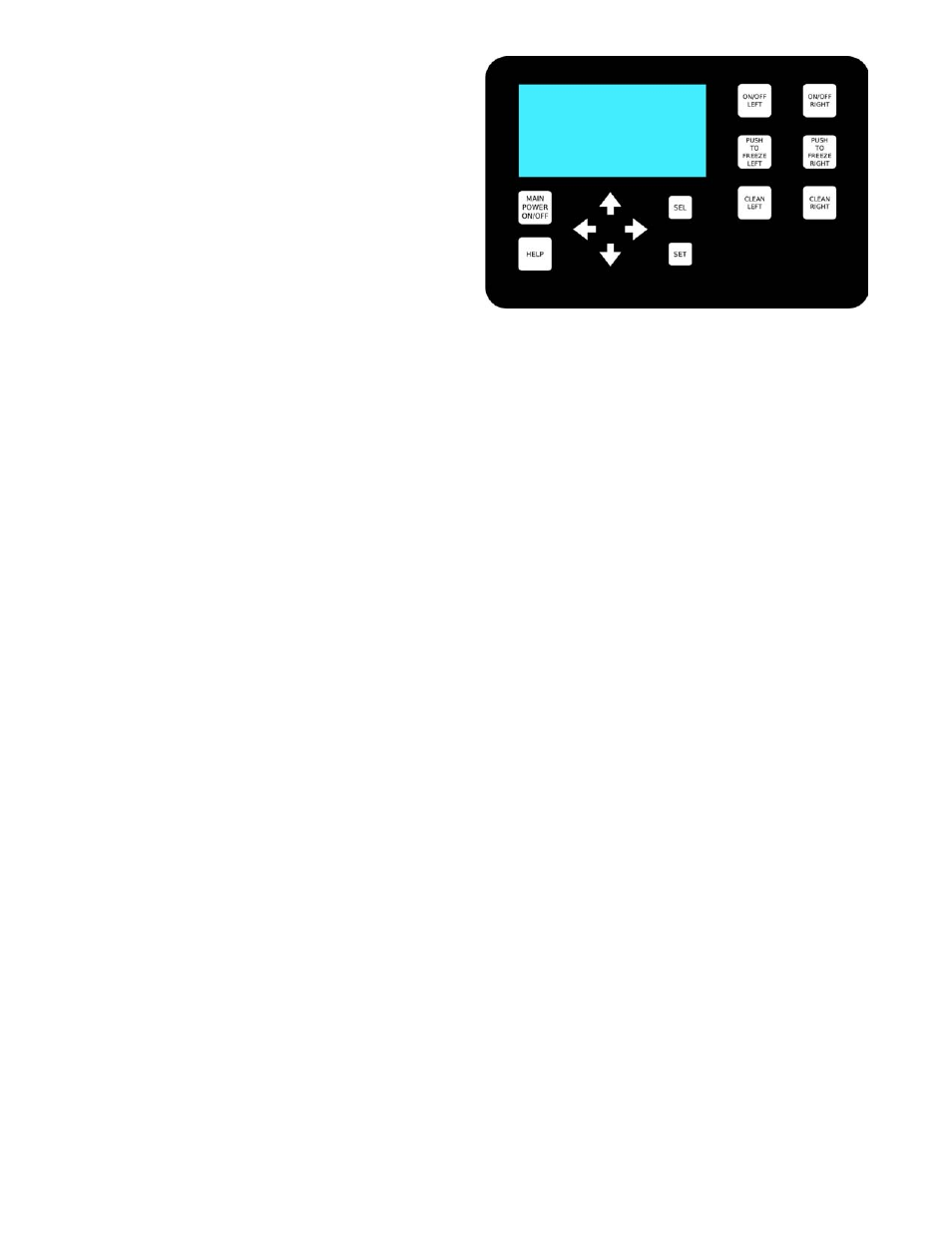

A. INTELLITEC2 TOUCHPAD

Main Power On/Off

The Main Power button is used to supply power to the

IntelliTec2 control, the freezing cylinder circuits and the

storage refrigeration system. When the machine is first

plugged in, the control defaults to the On status with power

to the hopper only. If the Main Power On/Off button is

pressed when the machine is on, the machine will turn off

and a status message will be displayed on the screen.

Help

Pressing the Help button will display help information

dependant on the cursor's location. Pressing the Help

button again will exit the help screen.

Selection Button (SEL)

The SEL button is used to select menu options. For details

of the menu options, refer to Section 4.

Set Button (SET)

The SET button is used to save changes when modifying

control settings. Refer to Section 4 for details.

On/Off Button

Power to the freezing cylinders can then be controlled with

the On/Off Left and On/Off Right switches.

Push to Freeze Button

Pressing the PUSH TO FREEZE button initiates "Serve

Mode".

Clean Button

The CLEAN button initiates "Clean Mode".

Arrow Buttons (

⇐, ⇑, ⇒, ⇓

⇐, ⇑, ⇒, ⇓

⇐, ⇑, ⇒, ⇓

⇐, ⇑, ⇒, ⇓

⇐, ⇑, ⇒, ⇓)

The arrow buttons are used to navigate through the control

readings and settings. Section 2 contains details on all the

readings and settings.

B. SPIGOT SWITCH

The spigot switch is mounted to the spigot cam assembly

behind the header panel. When the spigot is opened to

dispense product, the spigot switch opens and the "Serve

Mode" begins.

C. DISPENSE RATE ADJUSTOR

The dispense rate adjustor is located under the header

panel, to the immediate right of the spigot handles. Turn-

ing the knob counterclockwise will decrease the dispense

rate.

3.3 IMPORTANT INFORMATION REGARDING

CLEANING AND SANITIZING

Soft serve machines require special consideration when it

comes to food safety and proper cleaning and sanitizing.

The following information specifically covers issues for

cleaning and sanitizing frozen dessert machines. This

information is meant to supplement a comprehensive food

safety program.

SOIL MATERIALS ASSOCIATED WITH FROZEN

DESSERT MACHINES

MILKFAT/BUTTERFAT – As components of ice-cream/

frozen custard mix, these soils will accumulate on the

interior surfaces of the machine and its parts. Fats are

difficult to remove and help attribute to milkstone buildup.

MILKSTONE – Is a white/gray film that forms on equip-

ment and utensils that are exposed to dairy products.

These films will accumulate slowly on surfaces because of

ineffective cleaning, use of hard water, or both. Milkstone is

usually a porous deposit, which will harbor microbial

contaminants and eventually defy sanitizing efforts.

Once milkstone has formed, it is very difficult to remove.

Without using the correct product and procedure, it is

nearly impossible to remove a thick layer of milkstone.

(NOTE: general-purpose cleaners DO NOT remove

milkstone.) This can lead to high bacteria counts and a

food safety dilemma.

IT IS BEST TO CONTROL MILKSTONE ON A DAILY

BASIS BEFORE IT CAN BECOME A SIGNIFICANT FOOD

SAFETY PROBLEM.

In addition to food safety, milkstone can cause premature

wear to machine parts, which can add to costs for replace-

ment parts or possibly more expensive repairs if worn

machine parts are not replaced once they have become

excessively worn.

IMPORTANT DIFFERENCES BETWEEN CLEANING AND

SANITIZING

CLEANING vs. SANITIZING

It is important to distinguish between cleaning and sanitiz-

ing. Although these terms may sound synonymous, they

are not. BOTH are required for adequate food safety and

proper machine maintenance.

Figure 3-2 IntelliTec2 Control