Pfannenberg PAI User Manual

Page 11

11 / 46

685 408 005

CAUTION!

Chips may damage the switch cabinet.

If the required cutouts are only made in the switch cabinet

just before mounting of the air/air heat exchanger, make

sure that swarf is not allowed to enter the device hood by

using a cover sheet, for example.

Hint

To facilitate installation with heavy units, M8 lifting eyes can be

screwed into the upper fixing on the equipment housing. Simple

„one man installation“ is thereby possible.

8.2 Installation of side-mounted, bolt-on air/air heat

exchanger PAS

The mounting surface of the switch cabinet is to be provided with

cutout(s) and holes for air ventilation openings and for securing

the unit according to the accompanying sheet.

The drawing on the accompanying sheet also shows the location

of the electrical connections and ventilation openings.

1) Make cutout(s) and drillings for the air/air heat exchanger, if not

already provided in the switch cabinet (see drawing on

accompanying sheet).Remove burrs from the cut edges.

2) Position the profile seal around the rim of the cutout(s). Position

the seal so that the impact ends are facing downwards.

1)

Screw the two threaded studs included in the component

pack into the upper fixing point of the air/air heat exchanger.

Suspend the unit from outside onto the switch cabinet using

the threaded studs.

4) Use the screws, nuts and washers included in the component

pack to secure the air/air heat exchanger on the inner side of the

switch cabinet. Tighten up fixings so that the seal is compressed

to a thickness of 2 mm.

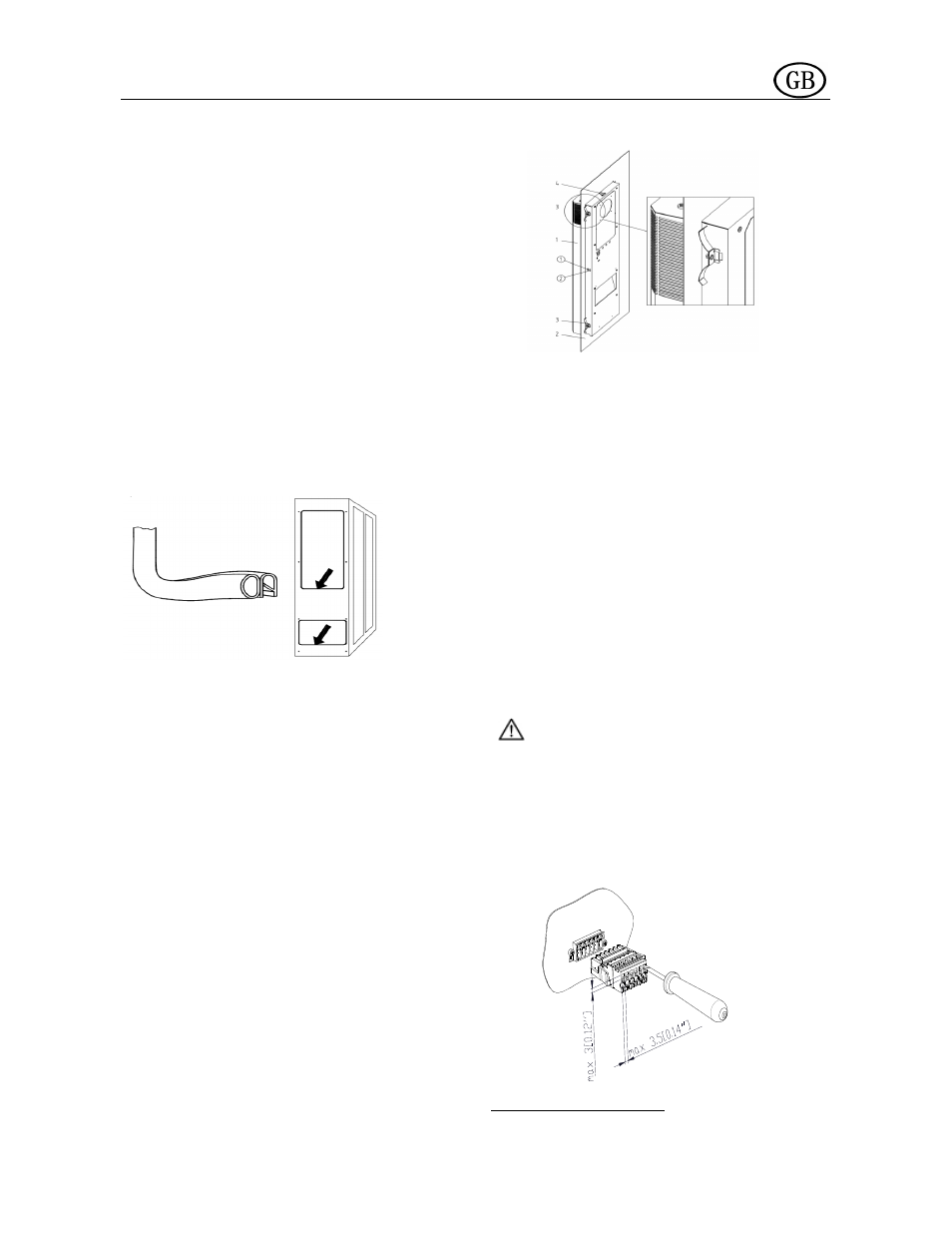

5) Clamp the cable as shown in the connection diagram (see back

of unit) to the plug (component pack) and connect to the unit.

- conductor size: 0,5 – 2,5mm² or AWG20 - AWG14 (In the

selection of cable size, the relevant regulations must be

observed!)

6) Connect the unit to the electrical supply (see section 8.4).

8.3 Installation of built-in air/air heat exchanger PAI

The mounting surface of the switch cabinet is to be provided with

a rectangular cutout as shown on the accompanying sheet. The

drawing on the accompanying sheet shows the location of the

ventilation openings after mounting the unit as seen from the

inside of the switch cabinet.

1) Make cutout for the air/air heat exchanger, if not already

provided in the switch cabinet (see drawing on accompanying

sheet).Remove burrs from the cut edges:

2) From the outside, insert the air/air heat exchanger (Pos. 1) into

the cutout and push through until the unit seal engages with the

switch cabinet (Pos. 2). Close the snap-fasteners (Pos.4) with

an audible click from the unit or upper side and secure the unit

against falling out.

1 air/air heat exchanger

2 Switch cabinet wall or door

3 Securing spring

4 Snap fastener

3) On the inside of switch cabinet, make sure that the securing

springs (Pos.3) supplied in the component pack rest in their

locations. To do this, compress the springs by hand so that

the securing bracket can be secured in the housing cutout.

In switch cabinets with reinforcing frames, insert the securing

springs in the housing cutouts.

4) Clamp cables in accordance with the connection diagram (see

rear of unit) to the plug-in connectors (enclosed package) and

connect to the unit.

- lead cross-section: 0.5 – 2.5 mm², and/or AWG20 –

AWG14 (for the selection of the cable cross-section

the relevant provisions are to be taken into account).

5) Connect the air/air heat exchanger to the power source (see

section8.4)

8.4 Power connection

CAUTION!

The air/air heat exchanger must be connected to the mains by

means of a disconnecting device with a contact gap of at least 3

mm when switched off.

No temperature control must be series-connected to the cooling

unit feed.

The fuse as indicated on the ID plate must be series-connected as

line protection.

Power connection and repairs, if applicable, may only be carried

out by authorized trained electricians.

Power supply connection (mains):

Both mains voltage and frequency must correspond to the