Mountings – Norgren PRA/862000/M IVAC Industrial cylinder User Manual

Page 4

PRA/862000/M

N/us 1.5.250.04

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

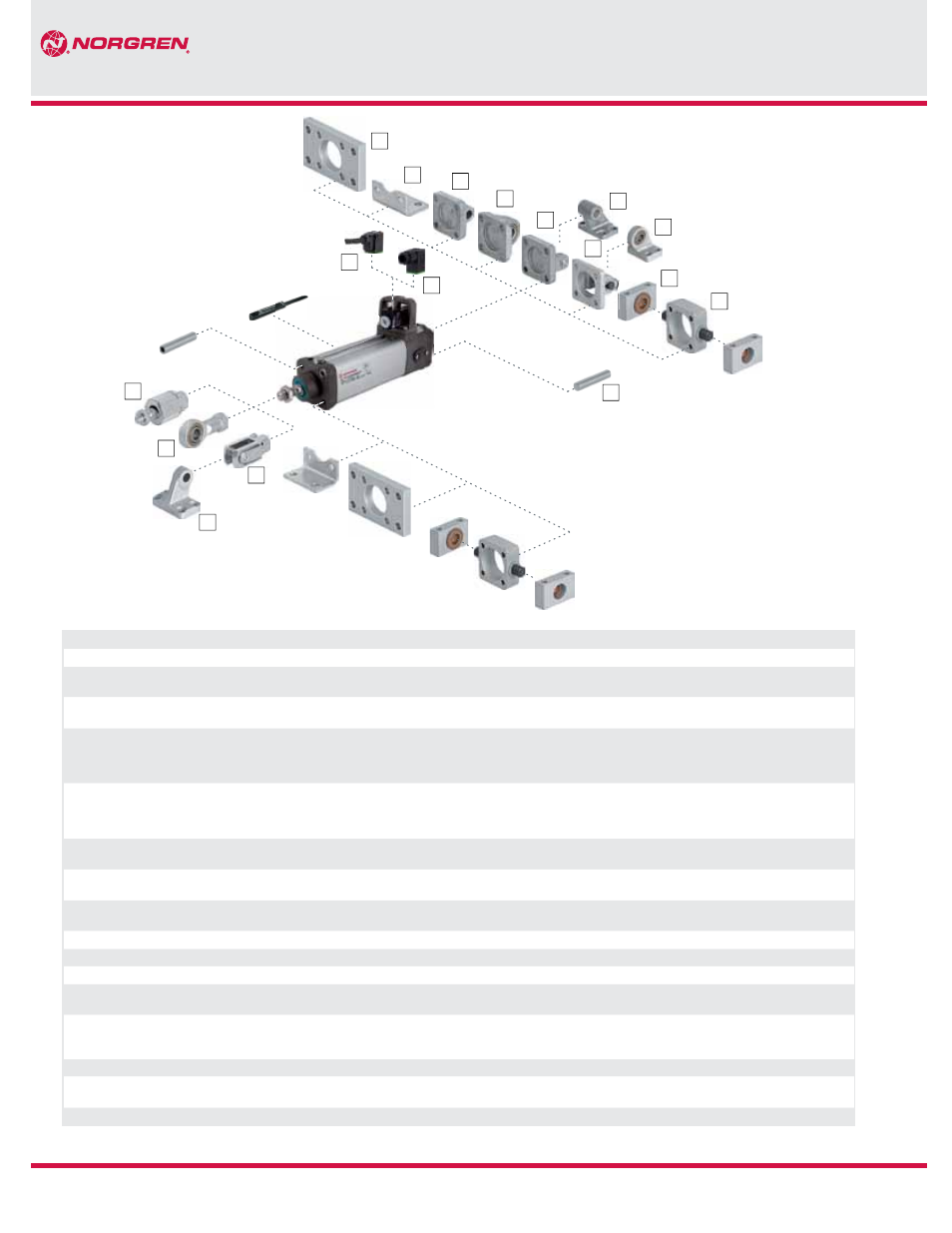

Mountings

Position

Style

Standard

Corrosion protected

1

B, G

Clear anodized aluminum

Clear anodised aluminium. Screws: A2

2

C

Galvanized steel (ø 32 ... 63 mm)

Painted steel (ø 80 & 100 mm)

—

3

R

Diecast aluminum

Black corrosion protected diecast aluminium. Certified

for the food industry. Screws: A2

4

UR

Galvanized aluminum

Inner ring: steel

Outer ring: brass

Black corrosion protected diecast alumin um

Certified for the food industry

Inner ring: stainless Steel (austenitic)

Outer ring: nickel plated hardened steel

5

D

Diecast aluminum

Bolt: galvanized steel (martensitic)

Circlip: galvanized steel

Black corrosion protected diecast aluminum

Certified for the food industry

Bolt: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

Circlip: Stainless steel (martensitic). Screws: A2

6

SW

Diecast aluminum

Black corrosion protected diecast aluminum

Certified for the food industry

7

US

Galvanized aluminium. Inner ring: steel

Outer ring: brass

—

8

D2

Painted cast iron. Bolt: stainless steel (martensitic)

Circlip: galvanized steel

—

9

FH

Cast iron

—

10

A

Galvanized steel

—

11

Screw

—

—

12

S

Clear anodised aluminum

Bearing: brass

15

F

Galvanized steel

Bolt: galvanized steel

Circlip: Galvanized steel

Nickel plated steel

Circlip: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

Bolt: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

16

SS

Painted cast iron

—

17

UF

Galvanized steel. Inner ring: steel

Outer ring: brass

Nickel plated steel. Inner ring: stainless steel (austenitic)

Outer ring: nickel plated hardened steel.

18

AK

Galvanized steel

—

1

15

16

17

18

10

21

22

2

3

4

5

7

6

9

12

8