Standard – Norgren PRA/862000/M IVAC Industrial cylinder User Manual

Page 12

PRA/862000/M

N/us 1.5.250.012

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

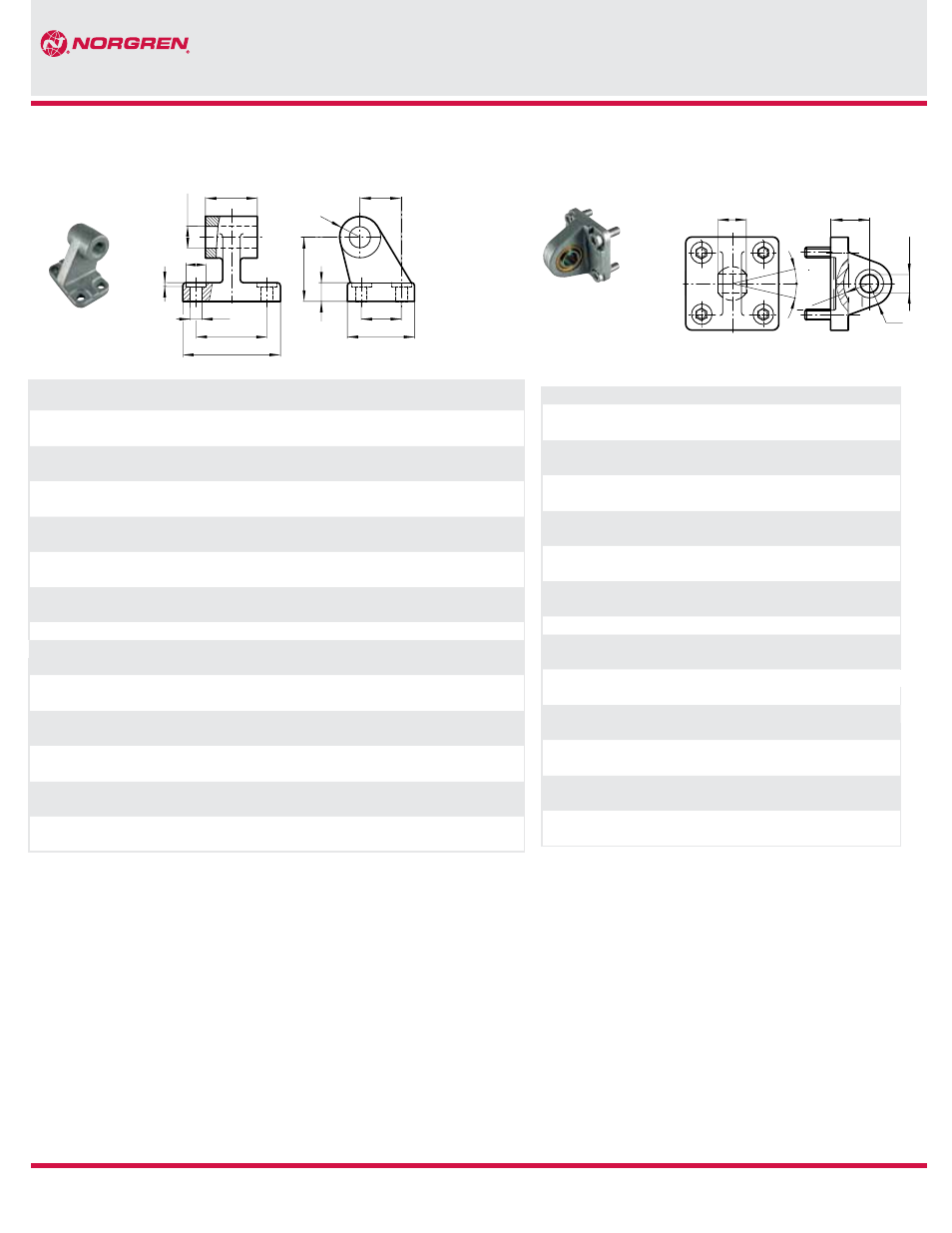

Wide hinge SW

Conforms to ISO 15552, type AB7

EM

K 1

K 2

ø S

ø D

L

1

ø

CK

H

9

G 2

G 3

G 1

R

CA

H

2

Ø

CA

Ø

CK

H9

Ø

D

H2

EM

G1

G2

G3

K1

K2

L1

R

Ø

S

lb.

(kg)

Model

(SW)

32

1.26

0.39

0.43

0.28

1.00

0.83

0.71

1.22

1.50

1.97

0.06

0.39

0.26

0.11

M/P19493

(32)

(10)

(11)

(7)

(25.5)

(21)

(18)

(31)

(38)

(50)

(1.6)

(10)

(6.6)

(0.05)

40

1.42

0.47

0.43

0.35

1.08

0.94

0.87

1.38

1.61

2.13

0.06

0.43

0.26

0.15

M/P19494

(36)

(12)

(11)

(9)

(27.5)

(24)

(22)

(35)

(41)

(54)

(1.6)

(11)

(6.6)

(0.07)

50

1.77

0.47

0.59

0.43

1.24

1.30

1.18

1.77

1.97

2.56

0.06

0.51

0.35

0.31

M/P19495

(45)

(12)

(15)

(11)

(31.5)

(33)

(30)

(45)

(50)

(65)

(1.6)

(13)

(9)

(0.14)

63

1.97

0.63

0.59

0.47

1.56

1.46

1.38

1.97

2.05

2.64

0.06

0.59

0.35

0.40

M/P19496

(50)

(16)

(15)

(12)

(39.5)

(37)

(35)

(50)

(52)

(67)

(1.6)

(15)

(9)

(0.18)

80

2.48

0.63

0.71

0.55

1.95

1.85

1.57

2.36

2.60

3.31

0.10

0.59

0.43

0.62

M/P19497

(63)

(16)

(18)

(14)

(49.5)

(47)

(40)

(60)

(66)

(84)

(2.5)

(15)

(11)

(0.28)

100

2.80

0.79

0.71

0.59

2.34

2.17

1.97

2.76

2.99

3.70

0.10

0.75

0.43

0.92

M/P19498

(71)

(20)

(18)

(15)

(59.5)

(55)

(50)

(70)

(76)

(94)

(2.5)

(19)

(11)

(0.42)

Corrosion protected mounts

32

1.26

0.39

0.43

0.31

1.04

0.83

0.71

1.22

1.50

2.01

0.06

0.39

0.26

0.11

M/P40459

(32)

(10)

(11)

(8)

(26.5)

(21)

(18)

(31)

(38)

(51)

(1.6)

(10)

(6.6)

(0.05)

40

1.42

0.47

0.43

0.39

1.12

0.94

0.87

1.38

1.61

2.13

0.06

0.43

0.26

0.15

M/P40460

(36)

(12)

(11)

(10)

(28.5)

(24)

(22)

(35)

(41)

(54)

(1.6)

(11)

(6.6)

(0.07)

50

1.77

0.47

0.59

0.47

1.28

1.30

1.18

1.77

1.97

2.56

0.06

0.51

0.35

0.31

M/P40461

(45)

(12)

(15)

(12)

(32.5)

(33)

(30)

(45)

(50)

(65)

(1.6)

(13)

(9)

(0.14)

63

1.97

0.63

0.59

0.47

1.59

1.46

1.38

1.97

2.05

2.64

0.06

0.59

0.35

0.40

M/P40462

(50)

(16)

(15)

(12)

(40.5)

(37)

(35)

(50)

(52)

(67)

(1.6)

(15)

(9)

(0.18)

80

2.48

0.63

0.71

0.55

1.99

1.85

1.57

2.36

2.60

3.39

0.10

0.59

0.43

0.62

M/P40463

(63)

(16)

(18)

(14)

(50.5)

(47)

(40)

(60)

(66)

(86)

(2.5)

(15)

(11)

(0.28)

100

2.80

0.79

0.71

0.59

2.38

2.17

1.97

2.76

2.99

3.78

0.10

0.75

0.43

0.92

M/P40464

(71)

(20)

(18)

(15)

(60.5)

(55)

(50)

(70)

(76)

(96)

(2.5)

(19)

(11)

(0.42)

Standard

Universal rear eye UR

Conforms to ISO 15552, type MP6

EN

Z

Z

FL

ER

R

CN

H

7

Ш

Ш CN

H7

EN

ER

FL

R

Z

lb. (kg) Model (UR)

32

0.39

0.55

0.63

0.87

0.57

0.33

QA/8032/33

(10)

(14)

(16)

(22)

(14.5)

13°

(0.15)

40

0.47

0.63

0.71

0.98

0.71

0.55

QA/8040/33

(12)

(16)

(18)

(25)

(18)

13°

(0.25)

50

0.63

0.83

0.83

1.06

0.75

0.88

QA/8050/33

(16)

(21)

(21)

(27)

(19)

15°

(0.4)

63

0.63

0.83

0.91

1.26

0.94

1.21

QA/8063/33

(16)

(21)

(23)

(32)

(24)

15°

(0.55)

80

0.79

0.98

1.10

1.42

0.94

1.98

QA/8080/33

(20)

(25)

(28)

(36)

(24)

15°

(0.9)

100

0.79

0.98

1.18

1.61

1.14

3.30

QA/8100/33

(20)

(25)

(30)

(41)

(29)

15°

(1.5)

Corrosion protected mounts

32

0.39

0.55

0.63

0.87

0.57

0.33

PVQA/8032/33

(10)

(14)

(16)

(22)

(14.5)

13°

(0.15)

40

0.47

0.63

0.75

0.98

0.71

0.55

PVQA/8040/33

(12)

(16)

(19)

(25)

(18)

13°

(0.25)

50

0.63

0.83

0.83

1.06

0.75

0.88

PVQA/8050/33

(16)

(21)

(21)

(27)

(19)

13°

(0.4)

63

0.63

0.83

0.94

1.26

0.94

1.21

PVQA/8063/33

(16)

(21)

(24)

(32)

(24)

15°

(0.55)

80

0.79

0.98

1.10

1.42

0.94

1.98

PVQA/8080/33

(20)

(25)

(28)

(36)

(24)

15°

(0.9)

100

0.79

0.98

1.18

1.61

1.14

3.30

PVQA/8100/33

(20)

(25)

(30)

(41)

(29)

15°

(1.5)

Standard