Commissioning, operation – WIKA TW10-P User Manual

Page 8

11405821.06 09/2010 GB/D/F/E

8

WIKA operating instructions thermowells

GB

Screw-fitting thermowells

When using parallel threads, a suitable seal should be used when mounting. Tapered threads

can be sealed by suitable seals or an additional welded seam. The correct tightening torques and

suitable tools (e.g. spanner) should be used.

Weld-fitting thermowells

Weld-in thermowells can be mounted into the process directly (pipe or vessel wall) or by using

a welding socket. Make sure that the weld seam is clean and that suitable equipment is used. If

necessary, heat-treat the weld seams.

Thermowells with flange connection

The flange dimensions of the thermowell must match those of the mating flange on the process

side. The seals used must be suitable for the process and the flange geometries (consult the

delivery note). The correct tightening torques and suitable tools (e.g. spanner) should be used

for installation. For thermowells with a collar, make sure that it matches the inner diameter of the

coupling and is supported by it. In the case of an interference collar, they should be adapted to the

inner diameter of the coupling.

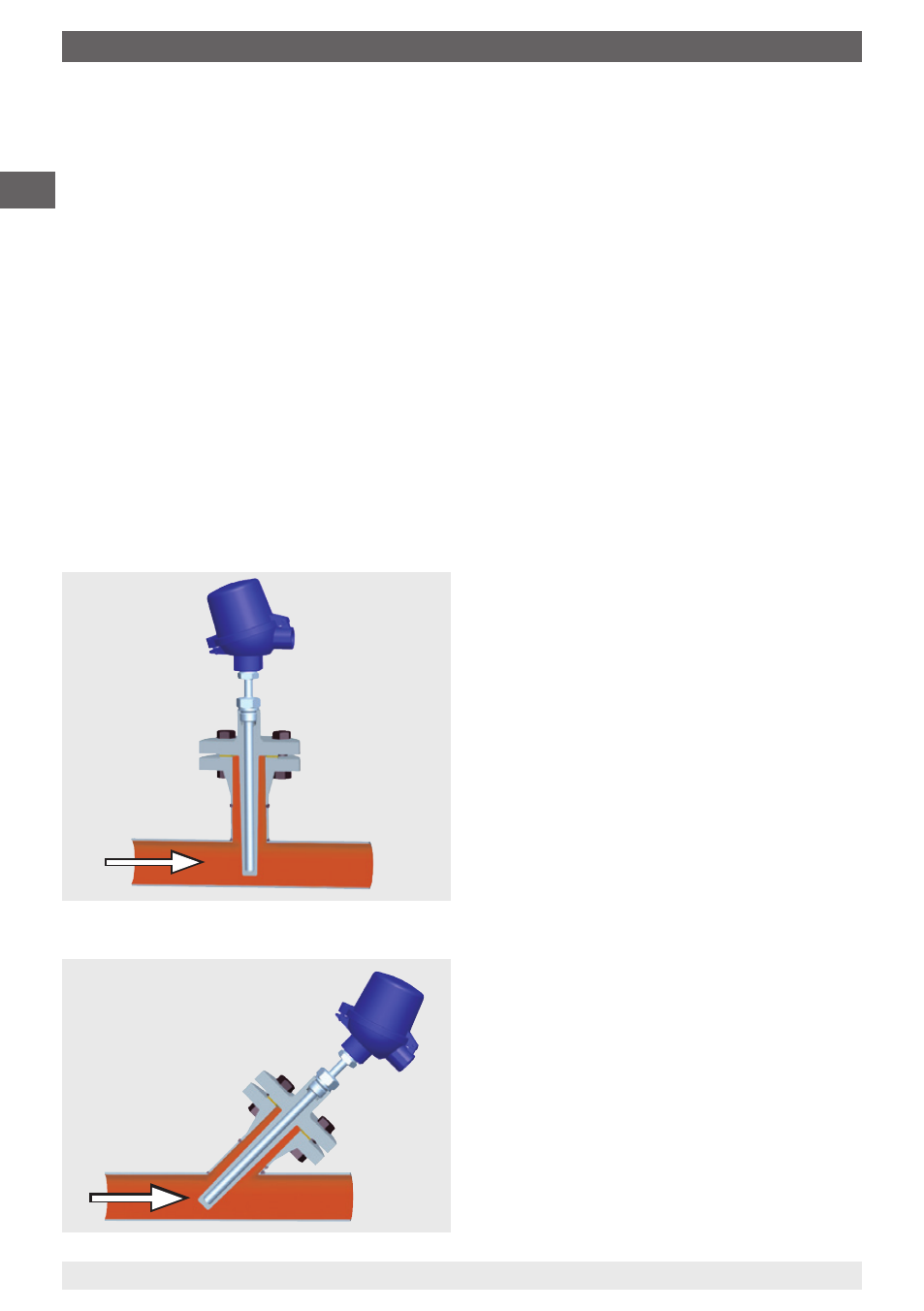

Irrespective of the process connection, 3 mounting positions of thermowells in pipes are possible:

■

Right-angled position with respect to the flow (most unfavourable position)

■

Tilted position with respect to the flow (tip inclined towards the flow direction is preferred)

6. Commissioning, operation