WIKA TW10-P User Manual

Page 7

WIKA operating instructions thermowells

11405821.06 09/2010 GB/D/F/E

7

GB

5.3 Storage

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects (for thermowells with plastic coating)

■

Mechanical vibration, mechanical shock (putting it down hard)

WARNING!

Before storing the thermowell (following operation), remove any residual media. This

is of particular importance if the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

6. Commissioning, operation

6.1 Mounting

During mounting (especially with ceramic thermowells) the thermowells should not be subjected

to thermal shocks or mechanical impacts.

Insert the thermowell into the process adapter without forcing or damaging it. The thermowell must

not be bent or altered in order to mount it.

The exception is the retrospective machining of the support ring in order that the thermowell is

supported free of play within the nozzle ("interference fit"). The retrospective adjustment of a

support ring with a loose fit is not permissible. In general, thermowells with a support ring are not

recommended within ASME PTC 19.3 TW 2010 and are outside of the scope of the standard.

It is recommended to mount the temperature measuring instrument into the thermowell using a

suitable sealing material to avoid, for example, humidity ingress.

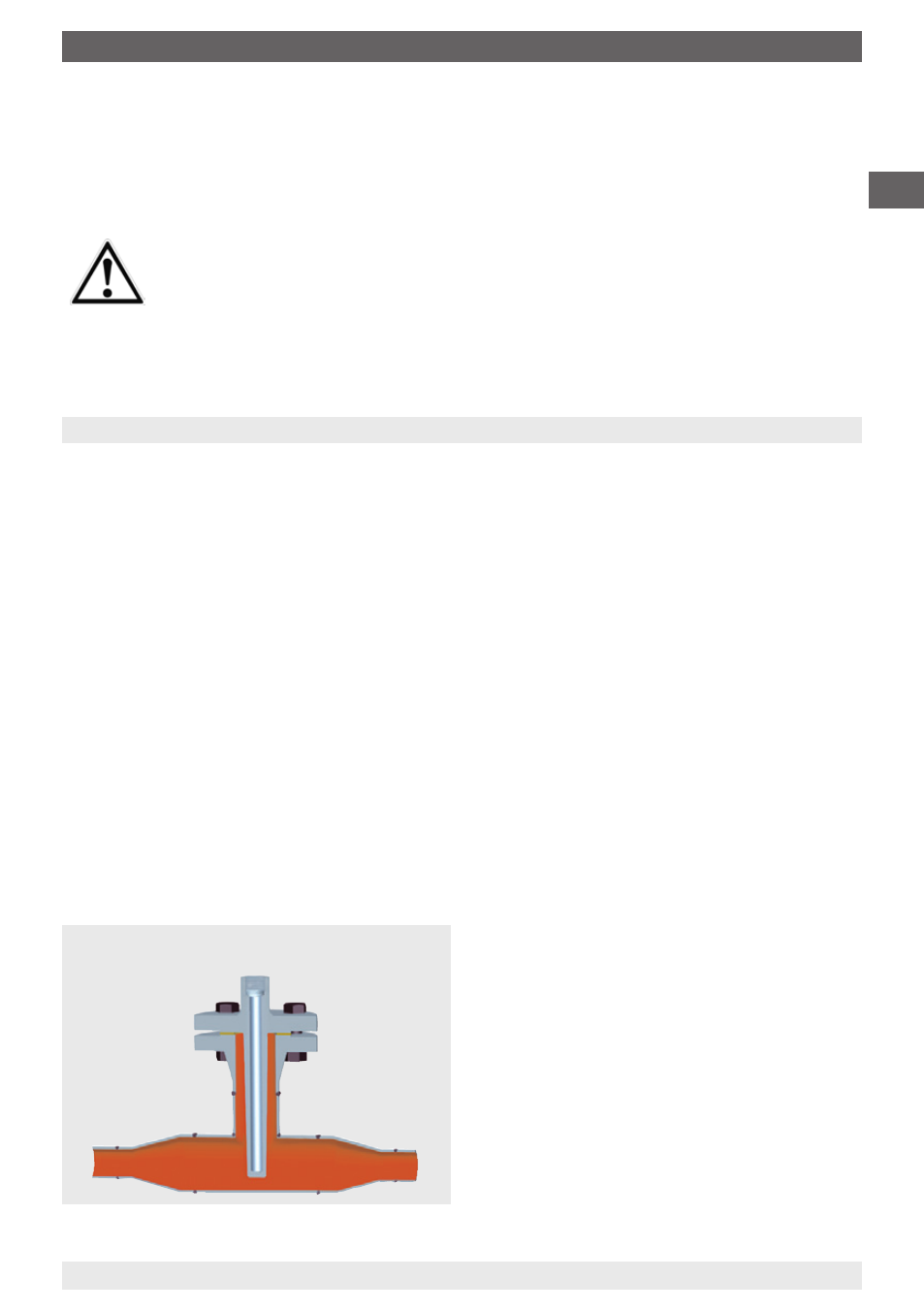

In general, the tip of the thermowell should be placed in the middle third of the pipe, though

the position may differ in special cases. It must be ensured that the measuring element (Pt100,

thermocouple, bimetal, etc.) is completely exposed to the medium and is not shielded by the

flange stubs. If, as a result of a small pipe diameter, this cannot be ensured, a pipe expansion can

be inserted around the measuring point.

Expansion of the pipe diameter

from DN 40 to DN 80

5. Transport, packaging and storage / 6. Commissioning, operation