WIKA 732.15.160 User Manual

Page 9

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions differential pressure gauge models 712.15.160, 732.15.160

9

GB

6. Application note ... 8. Transmitter for level measurement

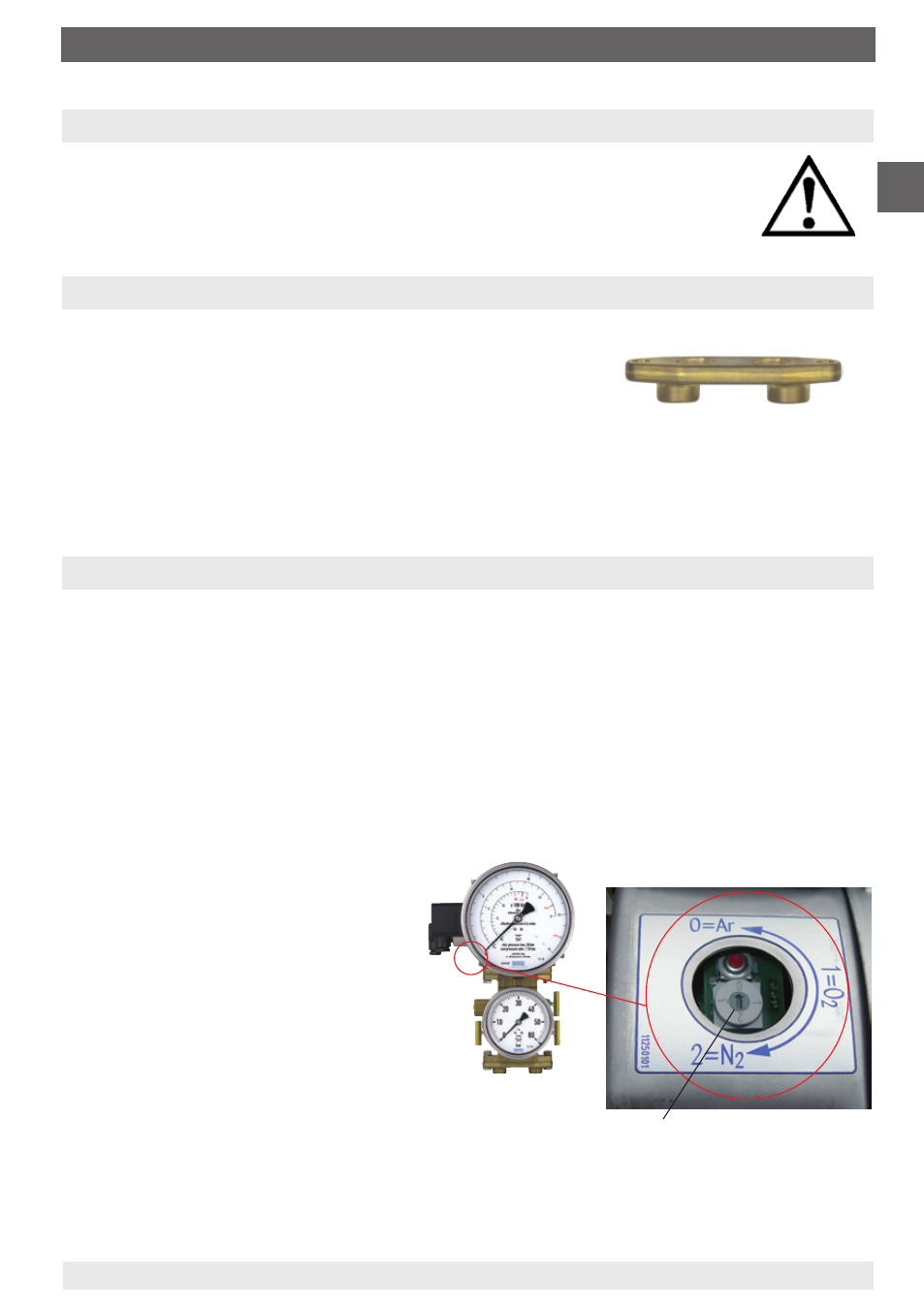

BCD switch (scale selection switch) and

zero point button (cover cap removed)

6. Application note

For dangerous media such as, for example, oxygen, acetylene,

combustible or acidic media, as well as for pressure vessels,

the general directives, and also the prevailing directives/guidelines

must also be adhered to.

7. Adapter for process connection (optional)

The adapters can be flange-connected either directly to

the differential pressure gauge or to the valve manifold.

5 different process connections are available:

2 x G 1/4, female, connection distance 31 mm or 54 mm

2 x 1/4 NPT, female, connection distance 31 mm, 37 mm or 54 mm

With a single order, all parts necessary for fitting to the differential pressure gauge or to the

valve manifold are included in the scope of supply:

2 x hexagon screw M8 x 16, 2 x hexagon screw M8 x 28, 2 x nut M8 and 2 x O-Ring seal

8. Transmitter for level measurement (optional)

Standard version model 891.44

Ex version model 892.44

WIKA differential pressure gauges with an integrated Model 89x.44 transmitter combines all

the advantages of an on-site mechanical display with the demands modern industry makes

for electrical signal transmission for the acquisition of measured values.

The transmitter is integrated into the housing of the level display. The measurement span

(electrical output signal) is set automatically by the mechanical display, i.e. the scale over a

swept angle of 270 degrees corresponds to 4 …20 mA (see section 4. Differential pressure

gauge).

With multiple scales or interchangeable

dials (optional) the output signal of

4 ... 20 mA corresponding to each,

can be stored in a microprocessor.

The output signal can be changed over

to the desired fluid type by rotating the

optional BCD switch (accessible through

a cover cap on the left side of the case)

using a screwdriver.

Electrical zero point (with option BCD switch)

If a zero point compensation is required (e.g. after mechanical zero point correction), press

the zero point button for approx. 1 sec. within 30 sec. with the voltage disconnected (remove

plug)

and with the pressure compensation valve open.