Transmitter for level measurement – WIKA 732.15.160 User Manual

Page 10

10

11265191.07 12/2012 GB/D/F/I

8. Transmitter for level measurement

WIKA operating instructions differential pressure gauge models 712.15.160, 732.15.160

GB

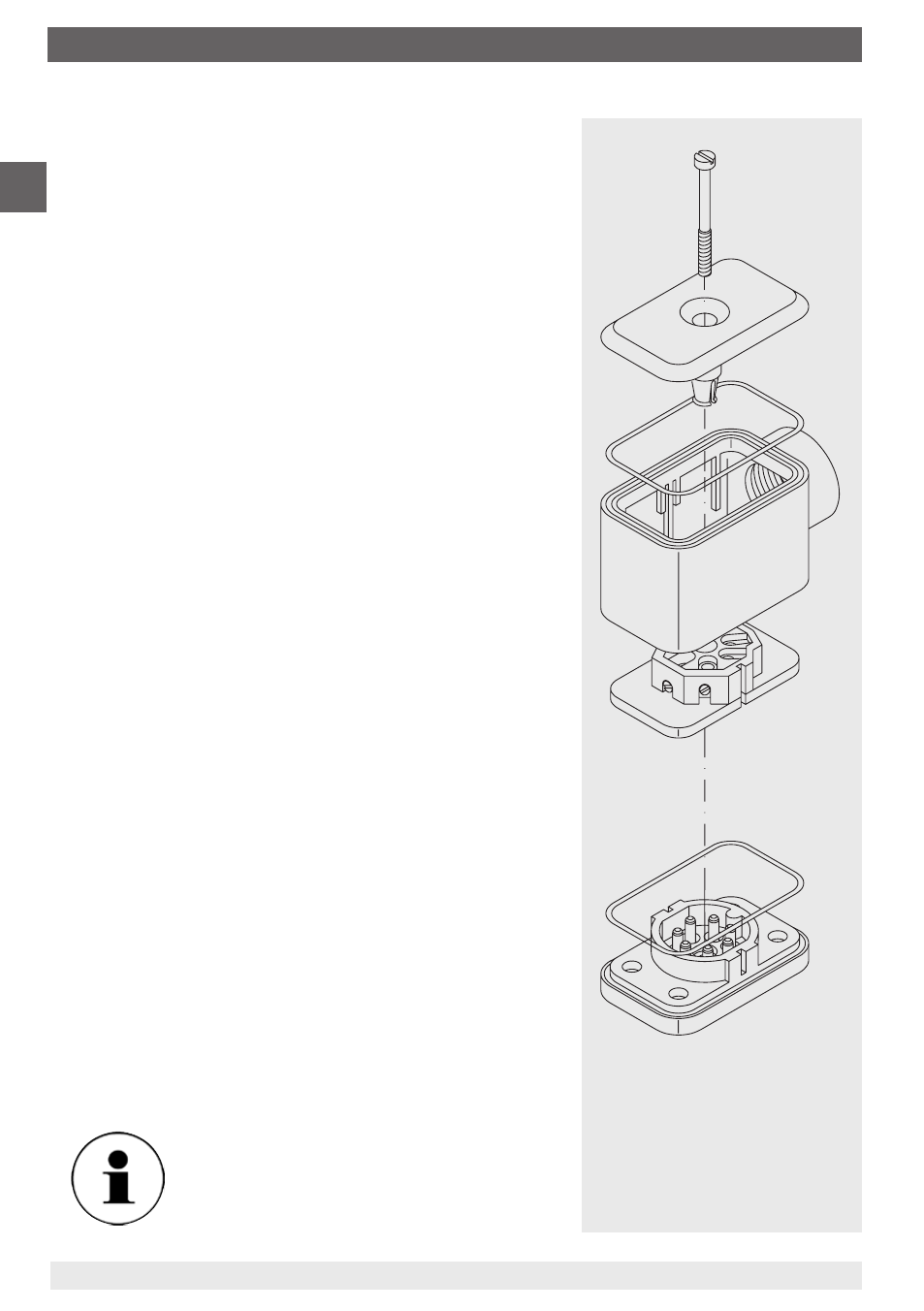

Electrical zero point (without option BCD switch)

If the mechanical zero point is changed by means of the

adjustable pointer, the electrical zero point must be reset to

the mechanical zero point.

First depressurise the pressure gauge.

Loosen the complete cable hood on the right-hand side of

the pressure gauge by completely unscrewing the screw

on the top of the cable hood cover

using an appropriate

screwdriver (0.6 x 3.5 mm).

Extract the screw. Remove the cable hood

with the

socket insert

from the cable socket base

and thus

separate the pressure gauge from the power supply.

Remove the cable hood cover

from the cable hood

and push the socket insert

out downwards through the

entire cable hood

.

Use a short stranded wire with bare points at both ends

(max. permissible resistance 30 Ω) to bridge contacts 5 and

6 on the socket insert.

Reassemble the plug in reverse order. Place the plug, with

the attached piece of stranded wire, onto the pin insert

,

and thus reestablish the power supply.

Within a max. 30 seconds the new zero point will be stored

within the electronics. During this period, the current in the

loop will increase to 9.5 mA.

The new zero point also remains stored in the case of a

power failure.

Loosen the plug again in the same sequence as descri-

bed above and remove the piece of stranded wire. After

reassembling the plug, the electrical output signal will once

more correspond to the indication of the mechanical pointer.

Ensure the seals

are properly and

securely reinstalled to maintain the

protection class.

Screw

Cable hood cover

Cable hood

Socket insert

Cable socket base

Seals