Storage, disposal – WIKA N-11 User Manual

Page 9

2147614.07 GB/D/F/E 04/2009

16 WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

17

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

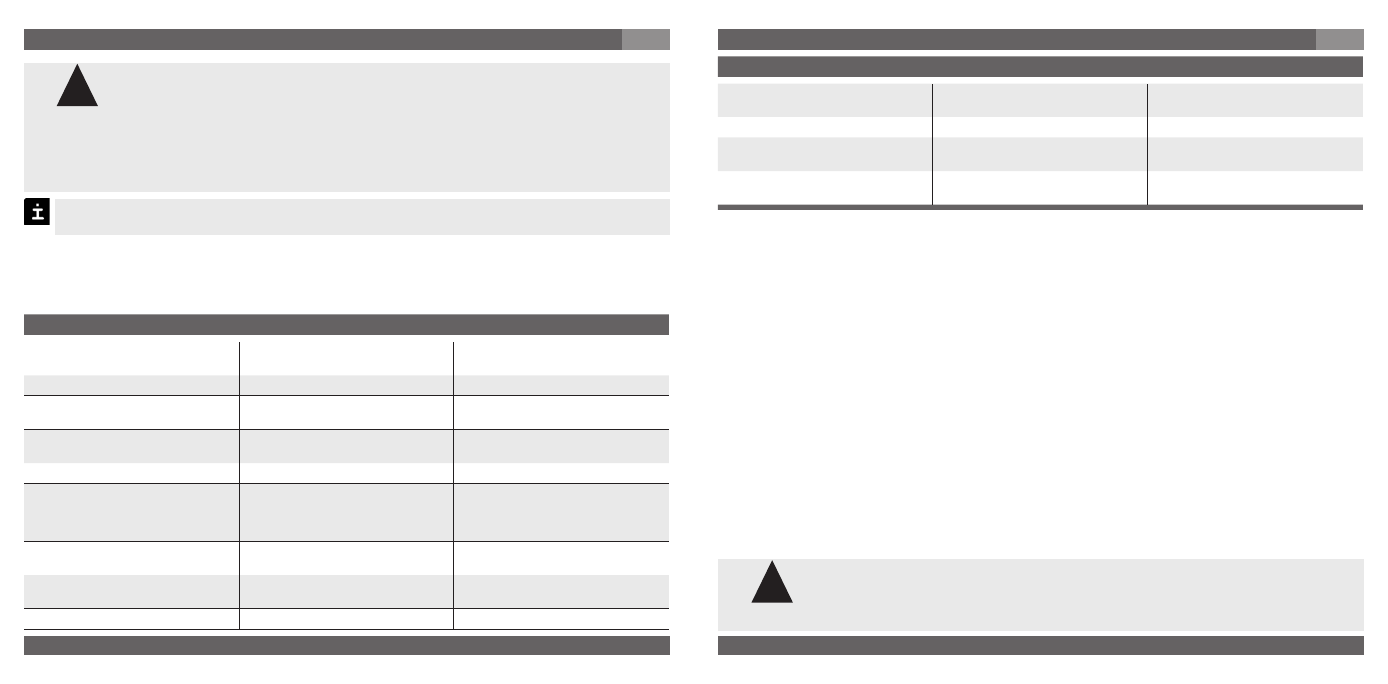

Failure

Possible cause

Procedure

No output signal

No/incorrect voltage supply or current

spike

Adjust the voltage supply to correspond

with the Operating Instructions *)

Cable break

Check connections and cable

No/False output signal

Incorrectly wired (e.g. Connected as

2-wire instead of 3-wire system)

Follow pin assignment (see Instrument

Label / Operating Instructions)

Output signal unchanged after change

in pressure

Mechanical overload through over-

pressure

Replace instrument; if failure reoccurs,

consult the manufacturer *)

Wrong supply voltage or current spike Replace instrument

Signal span dropping off/too small

Diaphragm is damaged, e.g. through

impact, abrasive/agressive media;

corrosion of diaphragm/pressure

connector; transmission fluid missing.

Contact the manufacturer and replace

the instrument

Signal span too small

Power supply too high/too low

Correct the power supply in line with

the Operating Instructions

Mechanical overload through over-

pressure

Re-calibrate the instrument *)

Signal span drops off

Moisture present (e.g. at the cable tail) Install the cable correctly

Failure

Possible cause

Procedure

Signal span erratic

Electromagnetic interference source in

the vicinity, e.g. inverter drive

Shield the device; shield the cables;

remove the interference source.

Instrument not grounded

Ground instrument

Strong fluctuations in the power supply Stabilise the power supply; smooth it

(i.e.; remove interferences)

Violent fluctuations in the process

media pressure

Damping; consult with manufacturer

9. Trouble shooting

GB

Do not insert any pointed or hard objects into the pressure port for cleaning to prevent

damage to the diaphragm of the pressure connection.

Take precautions with regard to remaining media in removed pressure trans-

mitters. Remaining media in the pressure port may be hazardous or

toxic!

Remove the pressure transmitter from service and mark it to prevent it from

being used again accidentally, if it becomes damaged or unsafe for opera-

tion.

Have repairs performed by the manufacturer only.

Please verify in advance if pressure is being applied (valves/ball valve etc. open) and if the

right voltage supply and the right type of wiring (2-wire/3-wire) has been chosen?

9. Trouble shooting / 10. Storage, disposal

GB

If the problem persists, contact our sales department.

USA, Canada

If the problem continues, contact WIKA or an authorized agent for assistance. If the pres-

sure transmitter must be returned obtain an RMA (return material authorization) number and

shipping instructions from the place of purchase. Be sure to include detailed information about

the problem. Pressure transmitters received by WIKA without a valid RMA number will not be

accepted.

Process material certificate (Contamination declaration for returned goods)

Purge / clean dismounted instruments before returning them in order to protect our employees

and the environment from any hazard caused by adherent remaining media.

Service of instruments can only take place safely when a Product Return Form has been

submitted and fully filled-in. This Return Form contains information on all materials with which

the instrument has come into contact, either through installation, test purposes, or cleaning.

You can find the Product Return Form on our internet site (www.wika.de / www.wika.com).

10. Storage, disposal

When storing or disposing of the pressure transmitter, take precautions with

regard to remaining media in removed pressure transmitters. We recom-

mend cleaning the transmitter properly and carefully. Remaining media in

the pressure port may be hazardous or toxic!

In case of unjustified reclamation we charge the reclamation handling expenses.

*) Make sure that after the setting the unit is working properly. In case the error continues to exist send in the instrument for reparation (or

replace the unit).

!

Warning

!

Warning