RMS Technologies IMDE23 INTEGRATED MOTOR+DRIVER+ENCODER User Manual

Page 9

RMS Technologies

Page 9

Version 1.17

R164 Controller Manual

09/15/2005

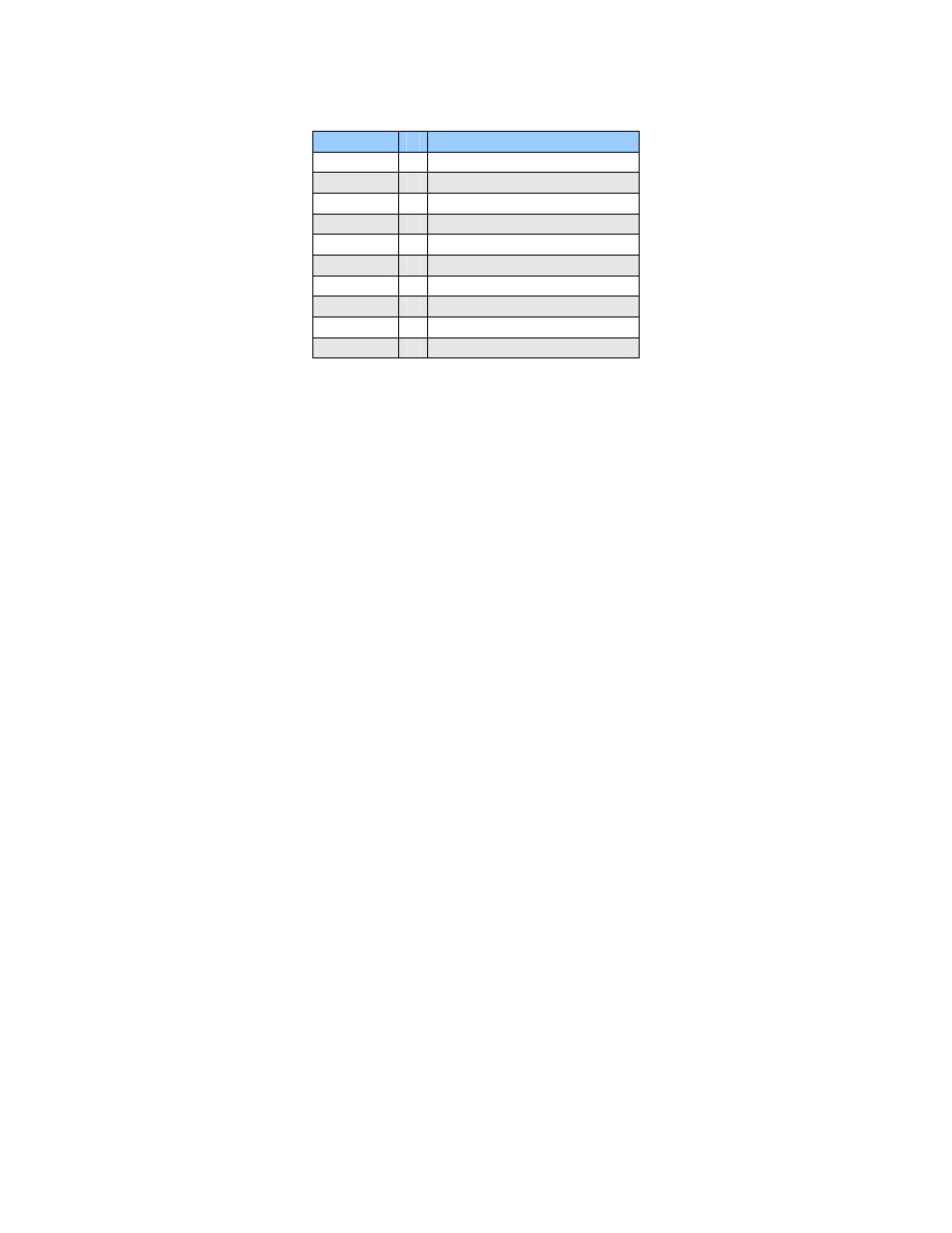

Percent

Desired Current (Amps)

10% =

0.15

20%

=

0.30

30% =

0.45

40%

=

0.60

50% =

0.75

60%

=

0.90

70% =

1.05

80%

=

1.20

90% =

1.35

100%

=

1.50

Table 3: Desired Current

To achieve the equivalent Driver Current (Amps), multiply your motor’s

rated current by 1.4. Follow these examples:

Example One:

You have a motor that is rated at 0.85 Amps, 0.85 Amps x 1.4 = ~1.2 Amps. Using

Table 3 we would see that 1.2 Amps is 80% of the driver’s maximum output current.

Assuming the R164 Controller is addressed to Number 1, this is what you’d program:

/

1l80m80R

Example Two:

You have a motor that is rated at 1.0 Amps, and your Controller is addressed to

Number 1, this is what you’d program:

/1l95m95R

This will set the controller to 1.4 Amps Peak. How did we get 1.4 Amps? Æ 1.0

Amps x 1.4 = 1.4 A

Example Three:

You have a motor that is rated at 1.0 Amps, but you would like to run it at 1.0 Amps

Peak. Using Table 3 we would see that 1.05 Amps is 70% is the correct setting.

This is what you’d program:

/1l70m70R

Example Four:

You have a motor that is rated at 0.35 Amps, here is the MAXIMUM current you are

able to use:

/1l33m33R

Programming anything higher than this will damage the motor.

WARNING!: Setting the Current to a value greater than the Motor’s rated

current will damage your motor, and may overheat the controller.