Dual – Rivera Primo Common Plenum Dual 42mm Mikuni Carburetor Kit (DMK) User Manual

Page 8

The jet that gives the shortest time is the correct

jet. This method is simple but effective.

FUNCTIONAL TUNING RANGE OF

COMPONENT PARTS

For best results, the accelerator pump nozzle

should be pointed directly at the jet needle. The

nozzle is held in place by the friction of an O-ring

and can be turned easily with a pair of long nosed

pliers. Nozzle adjustment should be made with a

minimum of pump strokes to avoid flooding the

engine.

SERVICING

There are very few moving parts in the HSR

series carburetor so it will not require much serv-

icing. There are a few items to be mentioned to

assure good performance season after season.

If it is ever necessary to disassembly your dual

carburetors, be certain to assembly all of the

parts back into the carburetor they were removed

from as some parts are not interchangeable

because of the custom nature of these carbure-

tors.

A. If the motorcycle is to be stored for any length

of time drain the floatbowl.

B. The float drain plug (main jet access) should

be removed periodically and cleaned of any sed-

iment that may have settled during long periods

of use.

C. DO NOT drill or modify any part of these car-

buretors for any reason as the result will surely

be more problems. Refer to this Tuning Section

to correct any problems that you may have.

D. If a jet or passage does become plugged, use

only carburetor cleaner and compressed air. DO

NOT push a drill or any other object through the

jet or passage to clean them.

E. Typical air filter service is done after about

2,000 miles of use. If the air filter is dirty (50% dirt

coverage) and requires servicing, follow these

steps.

1. PRE-CLEANING: Tap the element to dislodge

any large embedded dirt, then gently brush with a

soft bristle brush.

2. PAN CLEANING: Soak or roll element in a

large shallow pan of K&N air filter cleaner (1/4 the

depth of 1 pleat). Remove immediately and let sit

for approximately 10 minutes.

3. RINSE OFF: Rinse off the element with low

pressure water, tap water is OK. Always flush

from the inside of the filter out. This removes the

dirt and does not drive it into the filter. IMPOR-

TANT: Air dry only.

4. OILING: After the filter has dried always re-oil

before using. Apply K&N air filter oil with one

pass per pleat. Wait 10 minutes and re-oil any

white spots still showing. IMPORTANT: Do not

use gasoline or cleaning solvent to service the fil-

ter element as this will damage the filter.

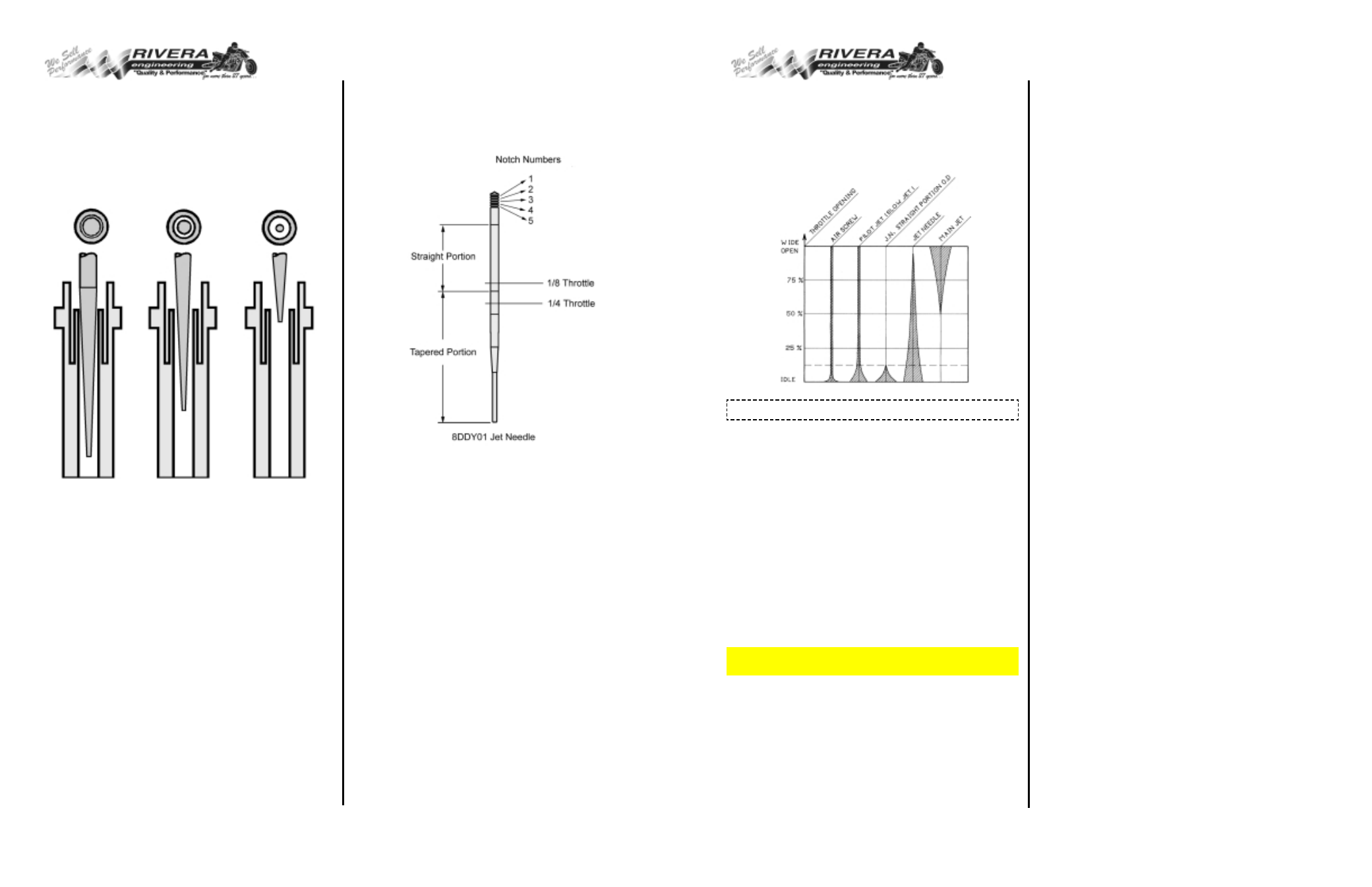

portion has its range of operation. The tapered

portion has an increasing effect on fuel mixture

from about 1/4 throttle opening as the tapered

section leaves the opening of the needle jet.

Between 1/2 and 3/4 throttle the influence of the

jet needle is the greatest and it controls most of

the fuel flow.

ll jet needle and main jet testing should be done

with the engine near the middle of its rpm range.

Start your acceleration tests at about 50 mph.

The best jet needle position will give the

strongest acceleration.

With the engine at operating temperature, accel-

erate at 1/2 to 3/4 throttle, in top gear from 50

mph or so. If acceleration seems soft or flat and

the engine is slow to respond when the throttle is

quickly opened from 1/2 to 3/4 throttle position,

the mixture is too lean. Raise the jet needle one

notch and repeat the test.

On the other hand, if acceleration is crisp but the

engines hesitates or staggers as the throttle is

suddenly shut down from 3/4 to 1/2 throttle, the

mixture is too rich. Lower the jet needle one

notch and repeat the test.

The jet needle position will be near correct when

acceleration is crisp at mid rpm yet the engine

does not load up during throttle shut down.

TUNING THE MAIN JET

You could in fact remove the main jet from your

Mikuni HSR and the engine would run fine until

the throttle was near the 3/4 mark. The jet needle

and needle jet restrict the amount of fuel getting

into the engine until about that point. There is no

point in changing main jets if a mixture problem

exists below the 3/4 throttle position.

The main jet is the last jet you need to deal with

and is the easiest to get right. If you have the

room, the most effective method for getting the

main jet right is to measure the time required to

accelerate between two points. The start and end

markers should be spaced so that starting at

about 35 mph at the first marker will have you

going past the second at near 55 mph.

Set up markers that are far enough apart, on a

safe road, to meet the conditions mentioned

above. When you pass the first marker roll the

throttle fully open and have a friend (it's easier

with help) measure the time need to get to the

second marker.

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

15

14

CAUTION

NOTE

1/4 throttle

full throttle

1/2-3/4throttle