Dual – Rivera Primo Common Plenum Dual 42mm Mikuni Carburetor Kit (DMK) User Manual

Page 6

Main system fuel is controlled by the taper from

where it begins to lift out of the needle jet until 3/4

throttle. Raising or lowering the needle will

respectively richen or lean the mixture.

At 3/4 throttle the orifice formed by the needle jet

becomes large enough that the size of the main

jet begins to control fuel flow. Until this point the

main jet has no effect on mixture strength. At full

throttle the needle taper has no influence.

ACCELERATOR PUMP

Mikuni HSR's are fitted with an accelerator pump.

The purpose of the pump is to inject fuel into the

throat of the HSR when the throttle is opened. As

the throttle is opened, especially at low rpm, air

velocity through the carburetor drops and the

mixture naturally leans out. Fuel from the pump

maintains a more correct air-fuel mixture until air

velocity increases.

The accelerator pump can be adjusted to inject

fuel into the throat of the carburetor over a wide

range of throttle openings. The rate at which it

injects fuel can be controlled with different size

pump nozzles. Total fuel volume depends upon

the pump's beginning and end point adjustments.

For the best performance from the accelerator

pump, the nozzle spray should be directed

toward the jet needle.

STARTER SYSTEM

The HSR's starter system is actually a small aux-

iliary carburetor designed to supply a rich mixture

that is required for starting and warm-up. The

starter system works when the choke knob is

pulled out and the throttle is in the closed posi-

tion.

If the throttle is opened with the choke knob

pulled out, air will cease flowing through the

starter system and it will stop delivering a rich fuel

mixture to the engine.

If the engine begins to load up while the starter

system is engaged, it may be cleared by opening

the throttle. When the throttle is closed, the

starter system will resume operation.

GENERAL TUNING PROCEDURES:

MIKUNI HSR CARBURETORS

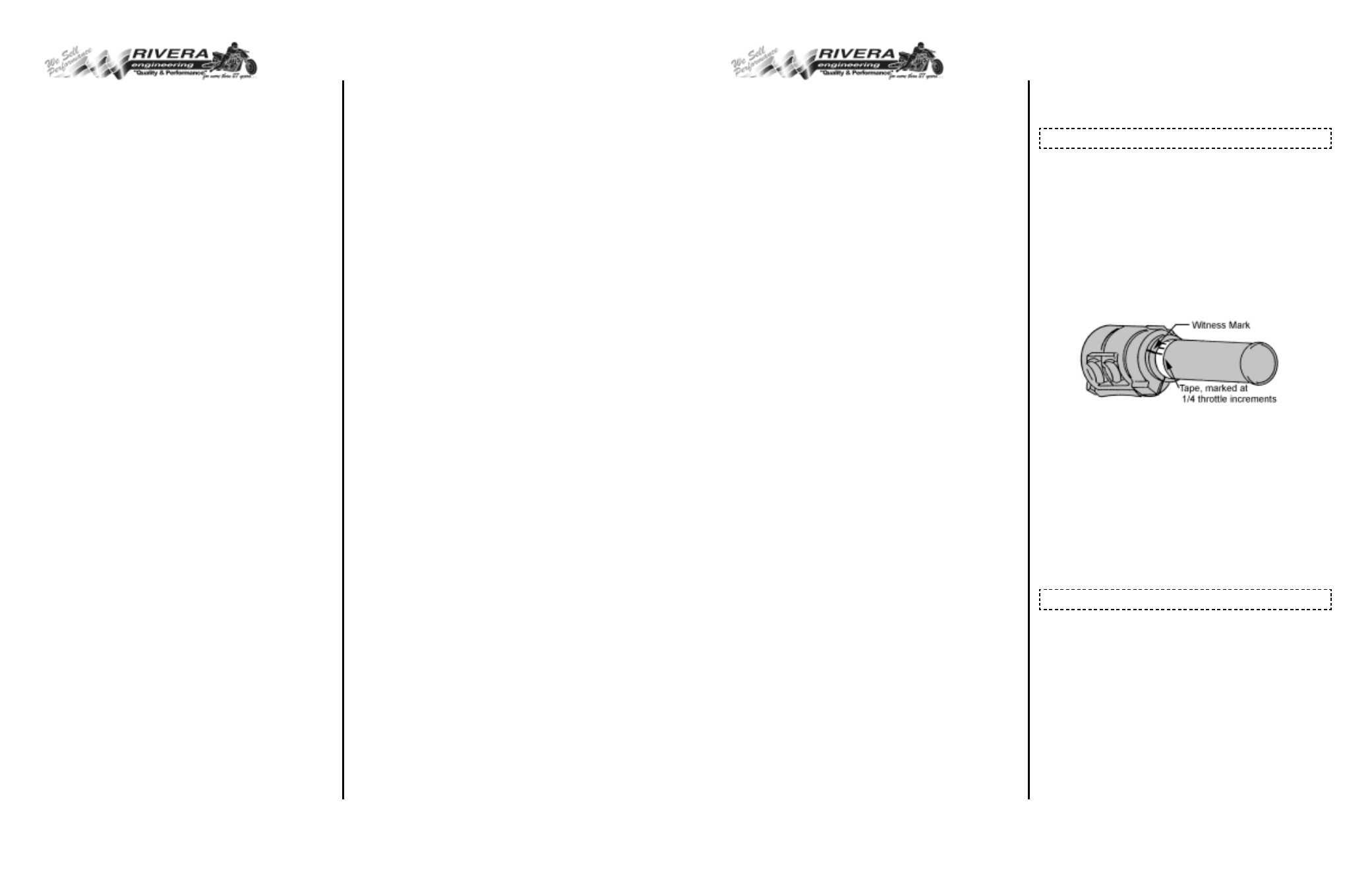

For the quickest and most accurate results fine

tuning your dual HSR's, we recommend using

"witness" marks, indicating the amount of throt-

tle opening, on the throttle grip and throttle

housing. Use masking tape on the grip and an

indicator mark on the throttle, with the grip tape

marked off in increments of 1/4 throttle open-

ings. In this way, you will be able to identify the

throttle opening where a tuning change may be

required and can adjust the correct carburetor

components.

Your Mikuni HSR is fitted with the tuning parts

we found to work with a majority of engine tun-

ing combinations. However, the tremendous

number of differing exhaust systems and cams

available for Harley engines makes it impossible

to accommodate all possible combinations with

one carburetor set-up. You will probably find that

the HSR will run perfectly on your engine with-

out exchanging any parts. But if it doesn't, you

may alter its tuning to suit your engines needs

by following this guide.

There are many more replaceable parts that

affect tuning in the HSR than in the stock Harley

carburetor. With these parts you will be able to

precisely tailor the HSR42 to your engine's

requirements throughout its rpm and throttle set-

ting range. Each tuning system is easy to modify

and diagnose, but only when you understand

what each system does and how it works. Before

making any alterations to the HSR, if any are

needed at all, read the section of this manual

describing the various tuning components and

their functional range.

BASIC PRINCIPLES OF

CARBURETOR OPERATION

As air passes through a carburetor, fuel is intro-

duced to obtain the correct air-fuel ratio. This is

accomplished with the help of a venturi. A venturi

is a restriction in the size of the carb body that air

flows through. As air flows through the venturi, its

speed increases because of the smaller area of

the passage. An increase in air speed causes a

corresponding reduction in air pressure. So, at

any given engine speed, the smaller the venturi,

the higher the air speed; the higher the air speed,

the lower the air pressure. HSR carbs use a slide

(technically, a variable venturi) to take maximum

advantage of this relationship.

The primary advantage of slide type carburetor

over a butterfly type is that as fuel is introduced

into the flow of air it is able to mix with all of the

incoming air and not just the portion of air that

passes below the butterfly throttle valve.

Additionally, the HSR incorporates 5 tunable cir-

cuits as compared to the butterfly type carburetor,

which utilizes only 3 circuits. The 5 circuits of the

HSR work progressively as the throttle is opened,

creating seamless throttle response and accel-

eration.

TUNING COMPONENTS

In this segment of the Tuning Section, each of the

HSR's tunable components is outlined and its

function described. Actual tuning procedures are

covered in the next segment: General Tuning

Procedures.

IDLE CIRCUIT (PILOT SYSTEM)

The idle circuit supplies fuel at idle speeds and

has a major influence on fuel flow up to 1/4 throt-

tle. There are two tunable parts in the idle circuit;

the pilot jet and air screw.

1.

PILOT JET-controls fuel flow through the

idle circuit.

2.

AIR SCREW-controls idle mixture. Turn

the screw out to lean the mixture, turn it in to

richen the mixture. The engine should have a

smooth, steady idle with the screw between 1

turn and 2 turns out from fully bottomed (gently!).

If the engine requires more than 3 turns out, the

pilot jet is too rich (large). If it requires less than

1/2 turn, the jet is too lean (small).

As the throttle is opened, the air screw's position

becomes less important than the sizes of the pilot

jet. A larger pilot jet richens the mixture from just

off idle to 1/4 throttle. A smaller jet leans it. After

changing the pilot jet, it will be necessary to re-

adjust the air screw for best idle.

MAIN SYSTEM

The main system delivers fuel from 1/16 to full

throttle, the idle circuit delivers the majority of

the fuel near 1/16 throttle. The main system

becomes the primary mixture control from about

1/4 throttle.

The main system has three tunable parts:

1.

NEEDLE JET-controls mixture from 1/16

to approximately 1/4 throttle (varies with needle

position).

2.

JET NEEDLE-controls mixture from 1/8 to

3/4 throttle.

3. MAIN JET-controls mixture from 3/4 to full

throttle.

The jet needle has a constant (straight) diame-

ter section and a tapered section. The outside

diameter of the jet needle and the inside diame-

ter of the needle jet form an orifice through

which all main system fuel must flow.

Until about 1/4 throttle, the constant diameter

section of the jet needle is within the needle jet

and main fuel flow is controlled by the size of

the jet needle.

Notches at the top of the jet needle allow it to be

raised or lowered. Raising or lowering the nee-

dle will determine at what throttle opening the

tapered part of the needle is raised out of the

needle jet.

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

11

10

NOTE

NOTE