Dual – Rivera Primo Common Plenum Dual 42mm Mikuni Carburetor Kit (DMK) User Manual

Page 7

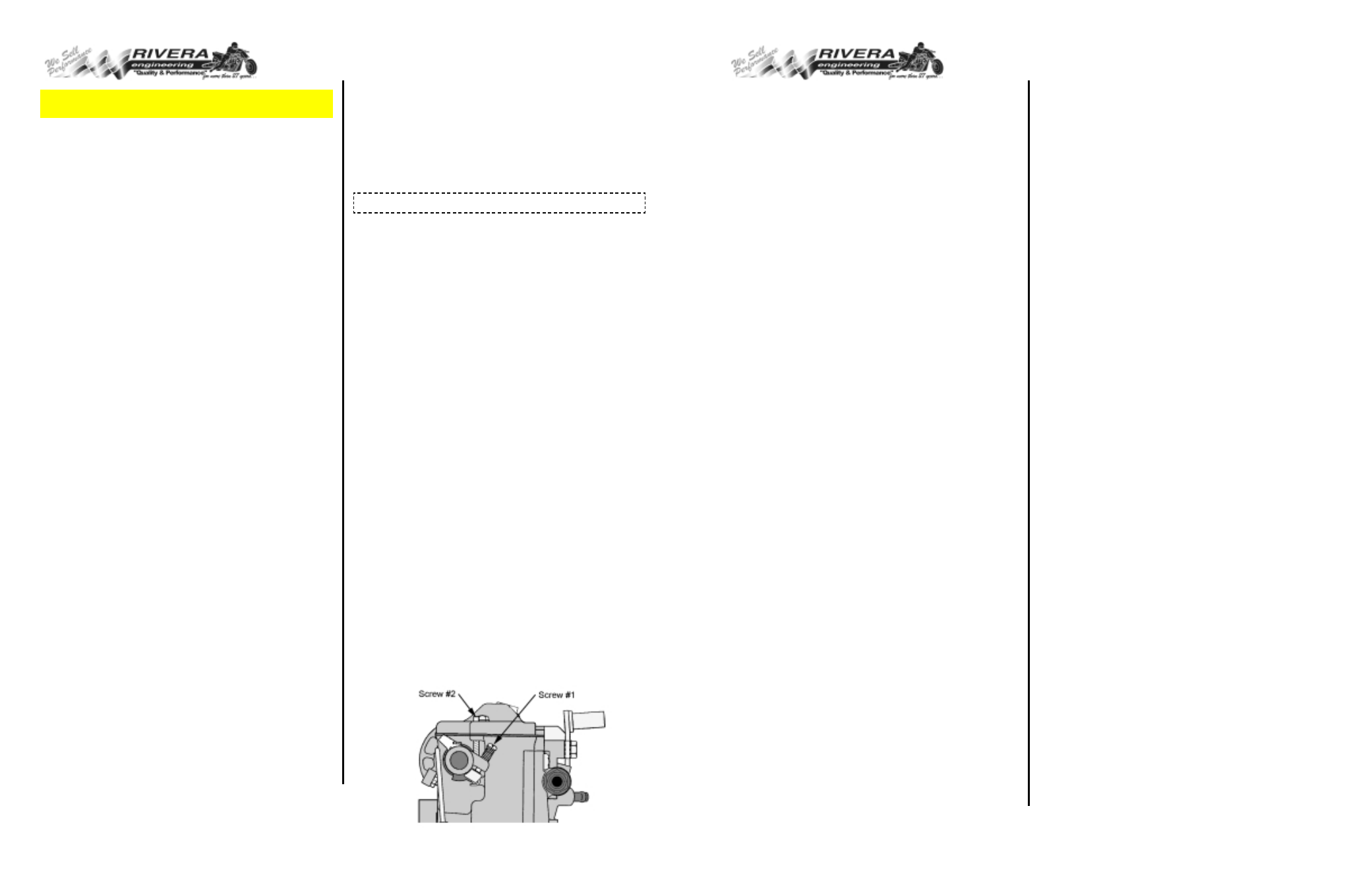

The beginning point of the pump stroke is adjust-

ed with the adjusting screw #1 on the white plas-

tic pump lever. To start the pump sooner, back the

screw out. Turn the screw in to make the pump

start its stroke at a larger throttle opening. Dual

carburetors perform best if the pump begins its

stroke as soon as the throttle is moved from the

idle position.

The end of the accelerator pump stroke is adjust-

ed by the adjusting screw #2 located on the top

of the carburetor just behind the pump lever. Best

performance is generally achieved when the

pump stroke ends before 1/2 throttle.

As a test to see if the accelerator pump is open-

ing at the correct time, screw in the #1 screw

(delaying opening) until there is a noticeable

engine hesitation as the throttle is opened. Then,

back the screw out until the hesitation disap-

pears, this should be the correct opening adjust-

ment.

To set the correct stopping point, screw in the #2

adjuster until the engine hesitates when the throt-

tle is opened. Then, back the screw out until the

hesitation disappears.

MAIN SYSTEM

TUNING THE JET NEEDLE

(Initial straight portion)

It is unlikely that you will need to change the jet

needle from the one supplied in your HSR42.

However, in case you do, you should be aware of

how it works and how to tell if the one you have

is too large (leaner) or too small (richer) for your

particular engine set up.

The initial straight portion of the jet needle affects

the mixture from idle to approximately 1/4 throttle,

at which point the needle's tapered portion takes

over.

LEAN CONDITION

If the jet needle is too lean (large), part throttle

acceleration will be flat. There may also be some

detonation during part throttle acceleration,

although this can also be caused by other fac-

tors. A lean jet needle will also result in a slow

warm-up.

If part throttle acceleration is flat, install a one

size smaller jet needle and compare the perform-

ance. If acceleration is improved, leave the small-

er jet needle in and take a ride at steady speeds

to give the spark plugs time to color evenly

Take a spark plug wrench with you and after a

few miles, stop and remove a plug for inspection.

Be careful as you stop not to operate the throttle.

The extra fuel from the accelerator pump can

cause a false plug reading. The porcelain around

the electrode should be from a light gray to brown

to dark gray. If the plug body is black and has a

sooty appearance the jet needle is probably too

rich and a larger one will need to be fitted.

RICH CONDITION

While a black sooty spark plug is a sure sign of

richness, there are others that are a bit more sub-

tle. If your engine responds crisply at low throttle

when it is cold, chances are the jet needle is one

size smaller than it needs to be. Assuming, of

course, that the idle circuit is correctly tuned.

Poor fuel mileage is another sign of richness and

because of the way most of us ride our Harleys,

that richness is usually the result of a jet needle

that is too small. The color of the end of the

exhausts is a sign of mixture strength. Dark gray

with some black is normal for today's lead free

gasolines. If the exhaust color is black, chances

are you can enlarge the size of the jet needle.

A slightly over-rich condition lets a Harley accel-

erate better at very low rpm's and from very low

throttle settings. It may be that you prefer a jet

needle or accelerator pump setting that is slight-

ly on the rich side of the correct range. Be aware

that you will lose some fuel economy if you

choose to do this.

TUNING THE JET NEEDLE

(Tapered portion)

Like the idle circuit of the jet needle, the tapered

There is little point in attempting to tune carbure-

tors unless the engine is completely sound.

Valves and rings must seal properly, the ignition

timing must be correct and the spark plugs clean

and gapped. Some exhaust systems may also

make carburetor tuning difficult. For instance, it is

very difficult to get smooth responsive carbure-

tion with straight and open pipes. If you have any

doubts about the condition of your engine, tune

and test it before beginning what could be a frus-

trating and unproductive effort to fix another prob-

lem with the carburetor.

PILOT SYSTEM

TUNING THE PILOT CIRCUIT

The first step in tuning this carburetor is to get the

idle circuit correctly adjusted. And the first step in

this procedure is to adjust the air screws for the

best idle. Mikuni sets the air screw at two turns

out during assembly. This is the position we have

found to be right most of the time. If the screw

position had been altered, gently bottom it and

re-open it to two turns out from the fully closed

position. The knurled knob above the air cleaner

is the adjuster for the second carburetor. Set

both air screws to the same number of turns dur-

ing tuning.

Next, ride the bike until the engine is at its normal

operating temperature. This may require several

miles at highway speeds. If you have an oil tem-

perature gauge, ride until the oil temperature is at

or near 150 degrees.

With the machine vertical and the engine idling

near 1,000 rpm, adjust the air screws in slowly

until the idle either slows or becomes irregular,

then begin turning them out until the engine again

slows or begins an irregular idle. Count the num-

ber of turns between the too rich and too lean

positions.

Set the air screw mid-way between the too rich

and too lean positions. You may further refine the

air screw position with further riding experience,

but this will provide you with the perfect idle mix-

ture setting.

If you allow the engine to get too hot during the

air screw adjustment procedure, the resulting

adjustment will probably be on the lean side of

correct. If you have a large fan, use it while

adjusting the mixture. If you do not have one, you

may need to take time out for a short ride to cool

the engine back to normal temperature.

If the best idle is achieved with the air screw less

than 1/4 turn out, the pilot jet is too small and will

need to be changed. On the other hand, if the air

screw must be more than three turns out for best

idle, the pilot jet is too large and will need to be

changed. Once you have a good idle with the air

screw within its range, you may proceed to the

next step.

ACCELERATOR PUMP SYSTEM

TUNING THE ACCELERATOR PUMP

The purpose of the accelerator pump is to inject

a metered amount of fuel into the engine at small

throttle openings. This is the time where air veloc-

ity is the lowest and this additional amount of fuel

enables the engine to rev up smoothly and quick-

ly. Mikuni HSR's use an accelerator pump in

order to achieve maximum fuel economy during

cruise throttle settings and still create a rich

enough condition for brisk throttle response.

Your dual HSR carburetors have the accelerator

pump installed in only one carburetor, this is the

carburetor closest to the engine. The accelerator

pump is factory set and should not require adjust-

ment under normal conditions.

The HSR's accelerator pump can be adjusted to

begin and end operation in response to the fuel

requirements of your particular engine.

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

DUAL

DUAL

CARB INST

CARB INST

ALLA

ALLA

TION

TION

13

12

CAUTION

NOTE