Goulds Pumps 3640 - IOM User Manual

Page 93

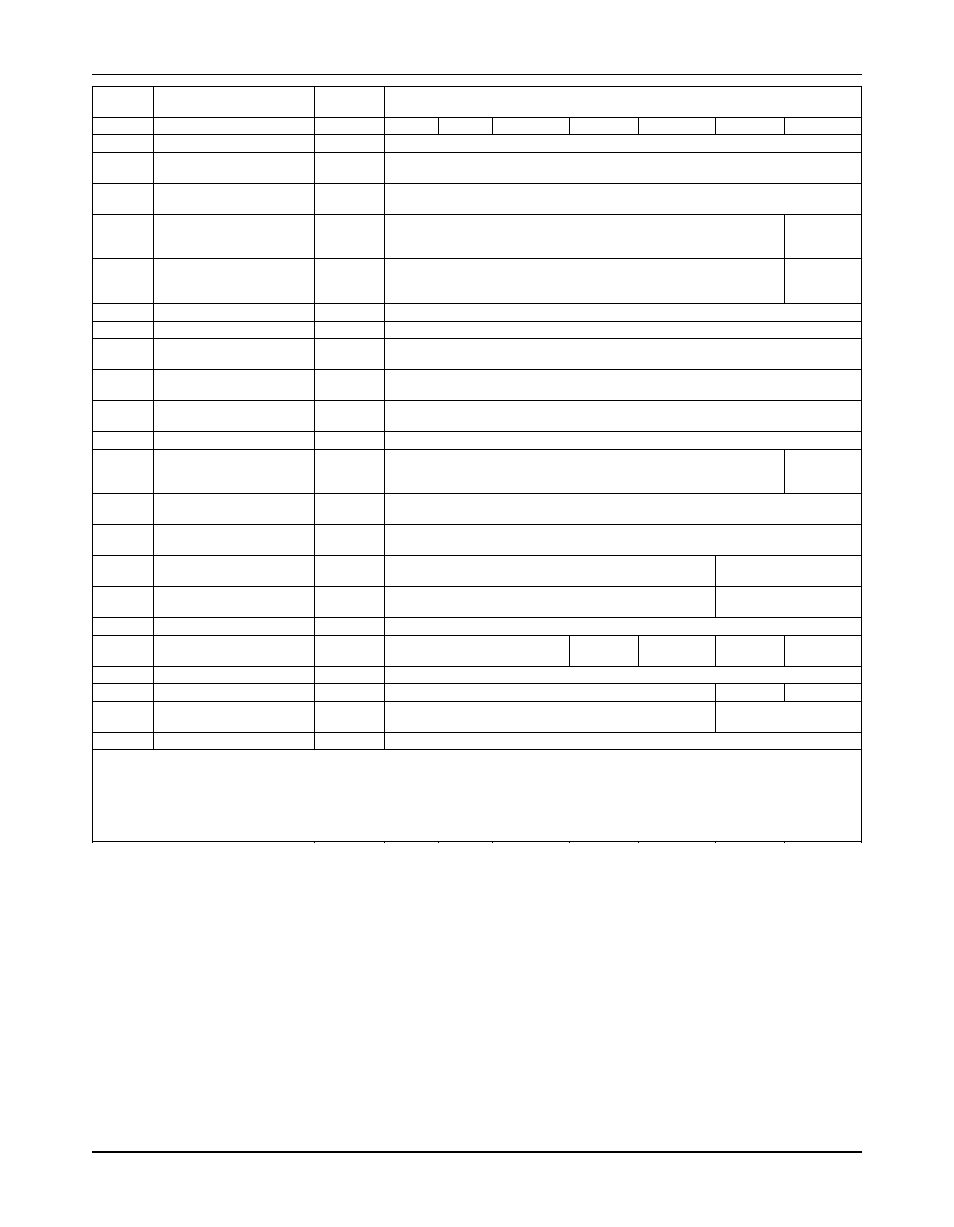

Parts Listings and Cross-Sectionals

Item

Part name

Quantity

Construction - API designation

per pump

S-4

S-5

S-6

S-8

C-6

A-8

D-1

324

Oil ring sleeve - radial end

1

Carbon steel

332A

Labyrinth seal, radial out-

1

Bronze

board

333A

Labyrinth seal, radial and

2

Bronze

thrust inboard

351

Gasket, casing

1

Spiral wound stainless steel

Spiral

wound du-

plex

351C

Gasket, head - inner

1

Spiral wound stainless steel

Spiral

wound du-

plex

353

Stud, gland

8

4140

355

Nut, gland stud

8

4140

356A,

Stud and nut, casing

Varies

4140

425

360A

Gasket, bearing end cov-

9

Vellumoid

er - radial and thrust

360S

Gasket, cooling jacket -

1

Sheet packing - graphite fiber

inner

4

360U

Gasket, cooling jacket

4

1

Sheet packing - graphite fiber

360W

Gasket, casing spacer

1

Spiral wound stainless steel

Spiral

wound du-

plex

371T/

Stud and nut, bearing

8

Carbon steel

427J

housing to casing/head

371C

Capscrew, bearing hous-

Varies

Carbon steel

ing end cover

388G

Socket head capscrew,

8

Carbon steel

316 SS

jacket - outer

4

388K

Socket head capscrew,

4

Carbon steel

316 SS

jacket - inner

4

400

Coupling key

1

Carbon steel

443A

Impeller sleeve

1

Nitronic 60

H.F. 316L Nitronic 60 H.F. 316L

H.F. du-

SS

1

SS

1

plex

1

443B

Thrust collar

1

Carbon steel

443D

Casing spacer

1

12% chrome

316 SS

Duplex

2

490/

Cover, water jacket

1

Carbon steel

304 SS

490A

520

Shaft nut

1

Carbon steel

1

Hardface with Colmonoy #6

2

ASTM A890 Grade 3A Duplex material will be supplied unless otherwise specified.

3

Standard material is 4140 steel. API requires material be upgraded on boiler feed service or when operating temperature

exceeds 350°F (180°C). ITT standard material will be 17-4PH (ASTM A564 Gr630) in lieu of the API recommended 12% chrome

steel.

4

Provided only with seal chamber cooling.

Model 3640 Installation, Operation, and Maintenance Manual

91