Goulds Pumps 3640 - IOM User Manual

Page 92

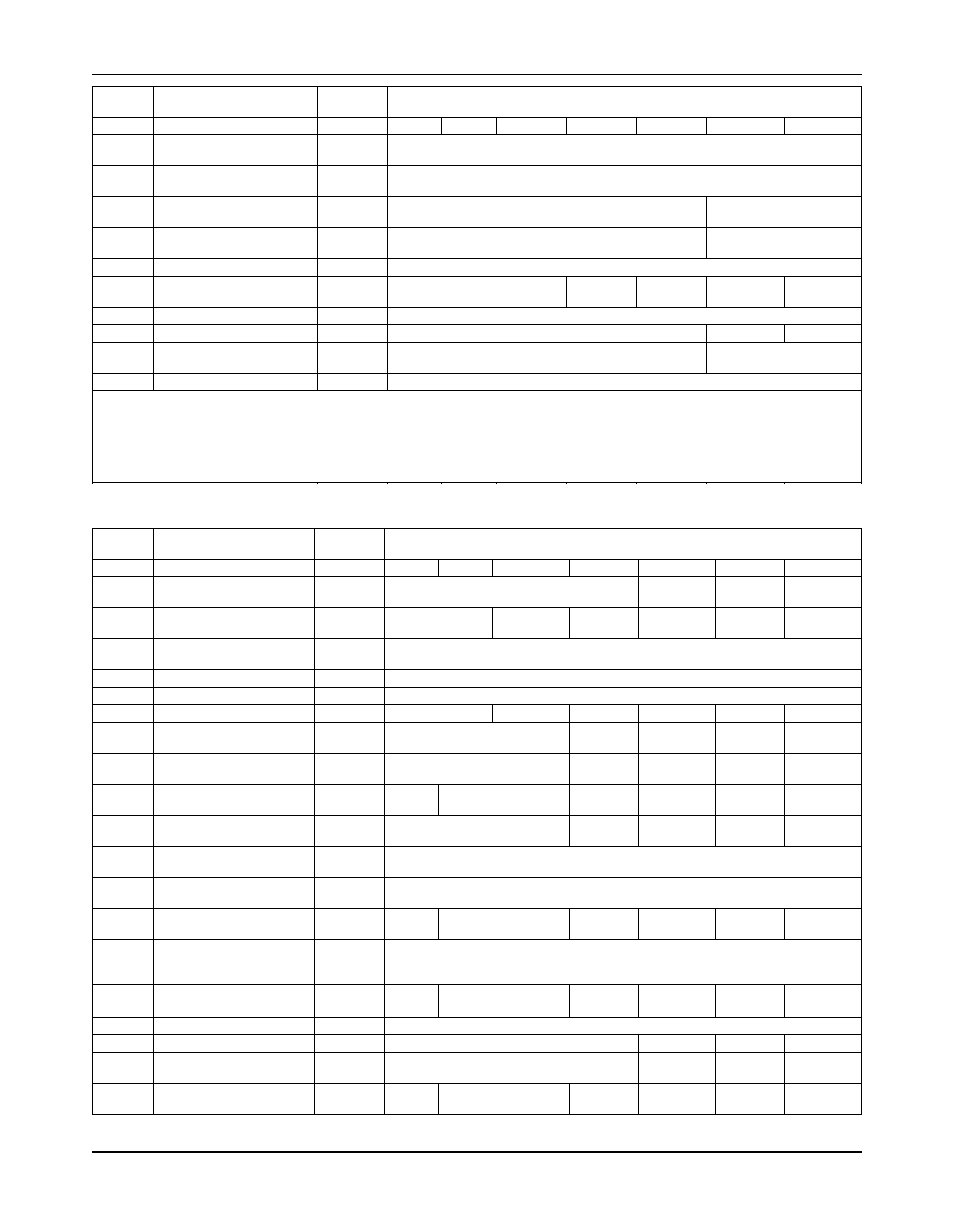

Parts Listings and Cross-Sectionals

Item

Part name

Quantity

Construction - API designation

per pump

S-4

S-5

S-6

S-8

C-6

A-8

D-1

371T/

Stud and nut, bearing

8

Carbon steel

427J

housing to casing

371C

Capscrew, bearing hous-

Varies

Carbon steel

ing end cover

388G

Socket head capscrew,

8

Carbon steel

316 SS

jacket - outer

4

388K

Socket head capscrew,

4

Carbon steel

316 SS

jacket - inner

4

400

Coupling key

1

Carbon steel

443A

Impeller sleeve

1

Nitronic 60

H.F. 316L Nitronic 60 H.F. 316L H.F. duplex

1

SS

1

SS

1

443B

Thrust collar

1

Carbon steel

443D

Casing spacer

1

12% chrome

316 SS

Duplex

2

490/

Cover, water jacket

1

Carbon steel

304 SS

490A

520

Shaft nut

1

Carbon steel

1

Hardface with Colmonoy #6

2

ASTM A890 Grade 3A Duplex material will be supplied unless otherwise specified.

3

Standard material is 4140 steel. API requires material be upgraded on boiler feed service or when operating temperature

exceeds 350°F (180°C). ITT standard material will be 17-4PH (ASTM A564 Gr630) in lieu of the API recommended 12% chrome

steel.

4

Provided only with seal chamber cooling.

Table 5: Parts list with materials of construction for ball bearing arrangement

The materials in this table are typical. Refer to the order documentation for the actual materials furnished.

Item

Part name

Quantity

Construction - API designation

per pump

S-4

S-5

S-6

S-8

C-6

A-8

D-1

100

Casing

1

Carbon steel

12%

316L SS

Duplex

2

chrome

101/145 Impeller

1 each

Carbon steel

12%

316L SS

12%

316L SS

Duplex

2

chrome

chrome

109A

Thrust bearing end cover,

1

Carbon steel

outboard

112A

Ball bearing, thrust

1 pair

Steel

114

Oil ring, thrust bearing

1

Brass

122

Shaft

1

4140

4140

3

Nitronic 50

17-4PH

Nitronic 50

Duplex

124

Impeller nut, radial end

1

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

SS

1

hardened

SS

1

plex

1

125/

Throat bushings

1 each

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

125B

SS

1

hardened

SS

1

plex

1

129

Throttle bushing

1

Cast

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

iron

SS

1

hardened

SS

1

plex

1

130

Impeller nut, thrust end

1

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

SS

1

hardened

SS

1

plex

1

134

Housing, bearing - radial

2

Carbon steel

and thrust

136/382 Bearing locknut and lock-

1

Steel

washer

142/ 144 Wear rings, impeller

1 each

Cast

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

iron

SS

1

hardened

SS

1

plex

1

160

Bearing end cover, radial

3

Carbon steel

(inboard and outboard)

and thrust (inboard)

164/

Wear rings, casing

2

Cast

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

164A

iron

SS

1

SS

1

plex

1

1 each

168

Bearing, radial

1

Steel

178

Key, impeller

1

303 SS

410 SS

303 SS

Duplex

184

Head

1

Carbon steel

12%

316L SS

Duplex

2

chrome

206

Spacer bushing

1

Cast

410 SS hardened

H.F. 316L

410 SS

H.F. 316L

H.F. du-

iron

SS

1

hardened

SS

1

plex

1

90

Model 3640 Installation, Operation, and Maintenance Manual