Assemble the optional water jacket cover, Post-assembly checks – Goulds Pumps 3640 - IOM User Manual

Page 86

Maintenance

NOTICE:

Make sure that the expulsion port is at the 6 o'clock position and is properly seated.

9. Install the upper half of the bearing housing (134).

10. Position the dowel pins between the upper and lower halves of the bearing housing.

Tighten the bearing-housing hex screws.

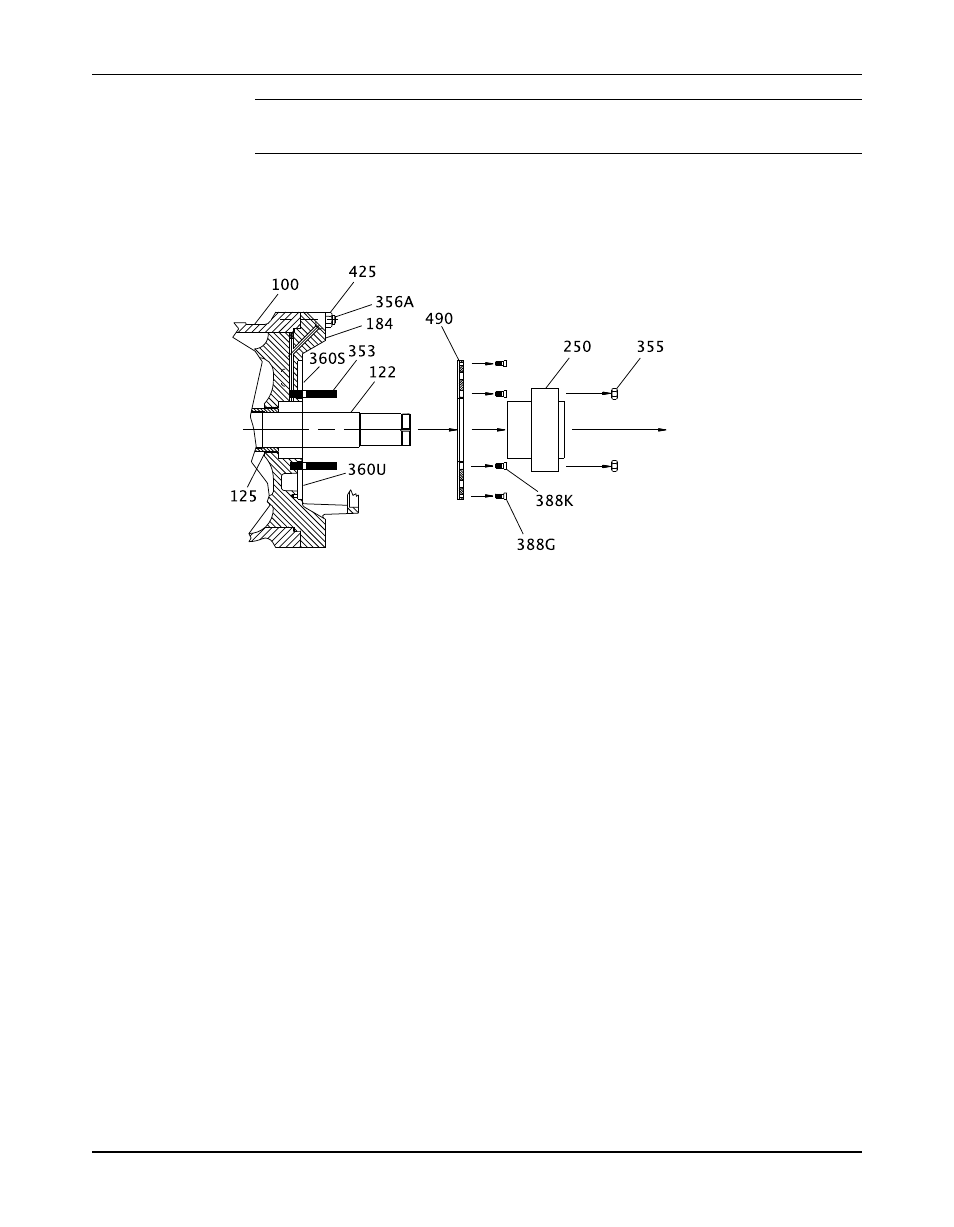

Assemble the optional water jacket cover

1. Install the water jacket cover gaskets (360S and 360U) on the case (100) and the head

(184).

2. Position the water jacket cover (490) on the case (100) and the water jacket cover (490A)

on the head (184).

3. Install the water jacket socket head capscrews (388G and 388K) and tighten evenly using

an alternating pattern. Torque the studs to the values given in the Maximum torque values

for fasteners table.

Assembly of the sleeve/Kingsbury bearing arrangement

If your pump is equipped with the rarely-supplied sleeve/Kingsbury bearing arrangement, refer

to the topics Assemble the radial end (sleeve/ball bearing pumps) and Assemble the thrust end

(sleeve/ball bearing pumps) for sleeve bearing reassembly.

Also see the instructions provided by Kingsbury for specific information regarding this tilting-

pad hydrodynamic bearing.

Post-assembly checks

Perform these checks after you assemble the pump, then continue with pump startup:

• Rotate the shaft by hand in order to make sure that it rotates easily and smoothly and that

there is no rubbing.

• Open the isolation valves and check the pump for leaks.

84

Model 3640 Installation, Operation, and Maintenance Manual