Auxiliary-piping checklist, Final piping checklist, Auxiliary-piping checklist final piping checklist – Goulds Pumps 3640 - IOM User Manual

Page 32

Installation

When to install a minimum-flow orifice

You can size and install a minimum-flow orifice in a bypass line in order to prevent bypassing

excessive flows. Consult your ITT representative for assistance in sizing a minimum-flow

orifice.

When a minimum-flow orifice is unavailable

Consider an automatic recirculation control valve or solenoid-operated valve if a constant

bypass (minimum-flow orifice) is not possible.

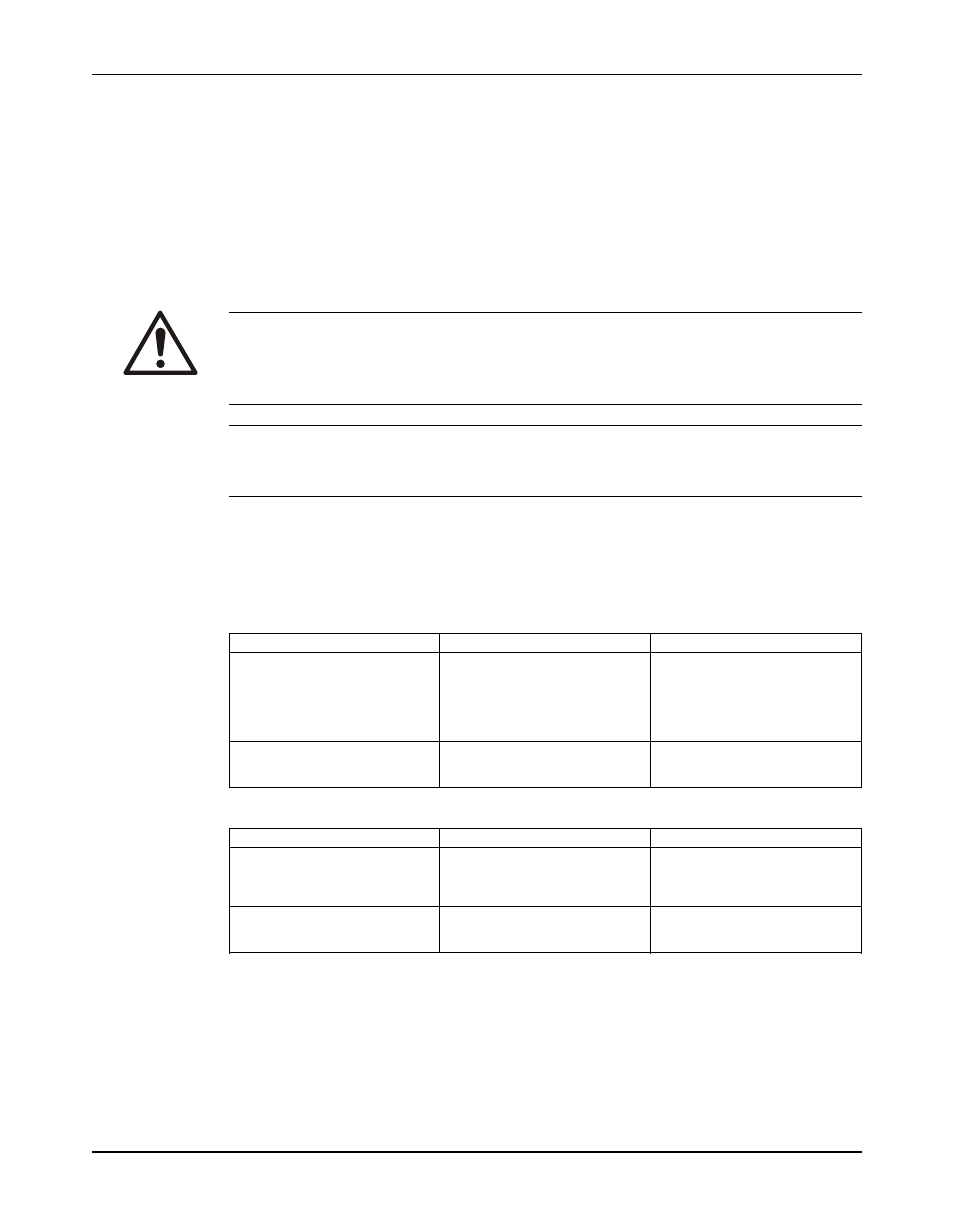

Auxiliary-piping checklist

Precautions

WARNING:

• Cooling systems such as those for bearing lubrication and mechanical-seal systems must be

operating properly to prevent excess heat generation, sparks, and premature failure.

• Sealing systems that are not self-purging or self-venting, such as plan 23, require manual venting

prior to operation. Failure to do so will result in excess heat generation and seal failure.

NOTICE:

The mechanical seal must have an appropriate seal-flush system. Otherwise, excess heat

generation and seal failure can occur.

When to install

You may need to install auxiliary piping for bearing cooling, seal-chamber cover cooling,

mechanical seal flush, or other special features supplied with the pump. Consult the pump data

sheet for specific auxiliary piping recommendations.

Checklist

Check

Explanation/comment

Checked

Check that the minimum flow for

–

each component is 1 gpm (4 lpm).

If the bearing and seal chamber

cover cooling are provided, then

the auxiliary piping must flow at 2

gpm (8 lpm).

Check that the cooling water pres- –

sure does not exceed 100 psig

(7.0 kg/cm

2

).

Final piping checklist

Check

Explanation/comment

Checked

Check that the shaft rotates

Rotate the shaft by hand. Make

smoothly.

sure there is no rubbing that can

lead to excess heat generation or

sparks.

Re-check the alignment to make

If pipe strain exists, then correct

sure that pipe strain has not

the piping.

caused any misalignment.

30

Model 3640 Installation, Operation, and Maintenance Manual