Bearings inspection – Goulds Pumps 3640 - IOM User Manual

Page 71

Maintenance

Rotor

Allowable runouts of the fully assembled rotor are listed in the Shaft and rotor runout

requirements table.

Table 2: Shaft and rotor runout requirements

Characteristic

Requirement

Flexibility factor, L

4

/D

2

>1.9x10

9

mm

(3.0x10

6

in.)

Allowable shaft runout, TIR

40 µm

(0.0015 in.)

Component fit to shaft

Clearance

Allowable rotor radial runout, TIR*

90 µm

(0.0035 in.)

*Total indicated runout of impeller hubs and sleeves

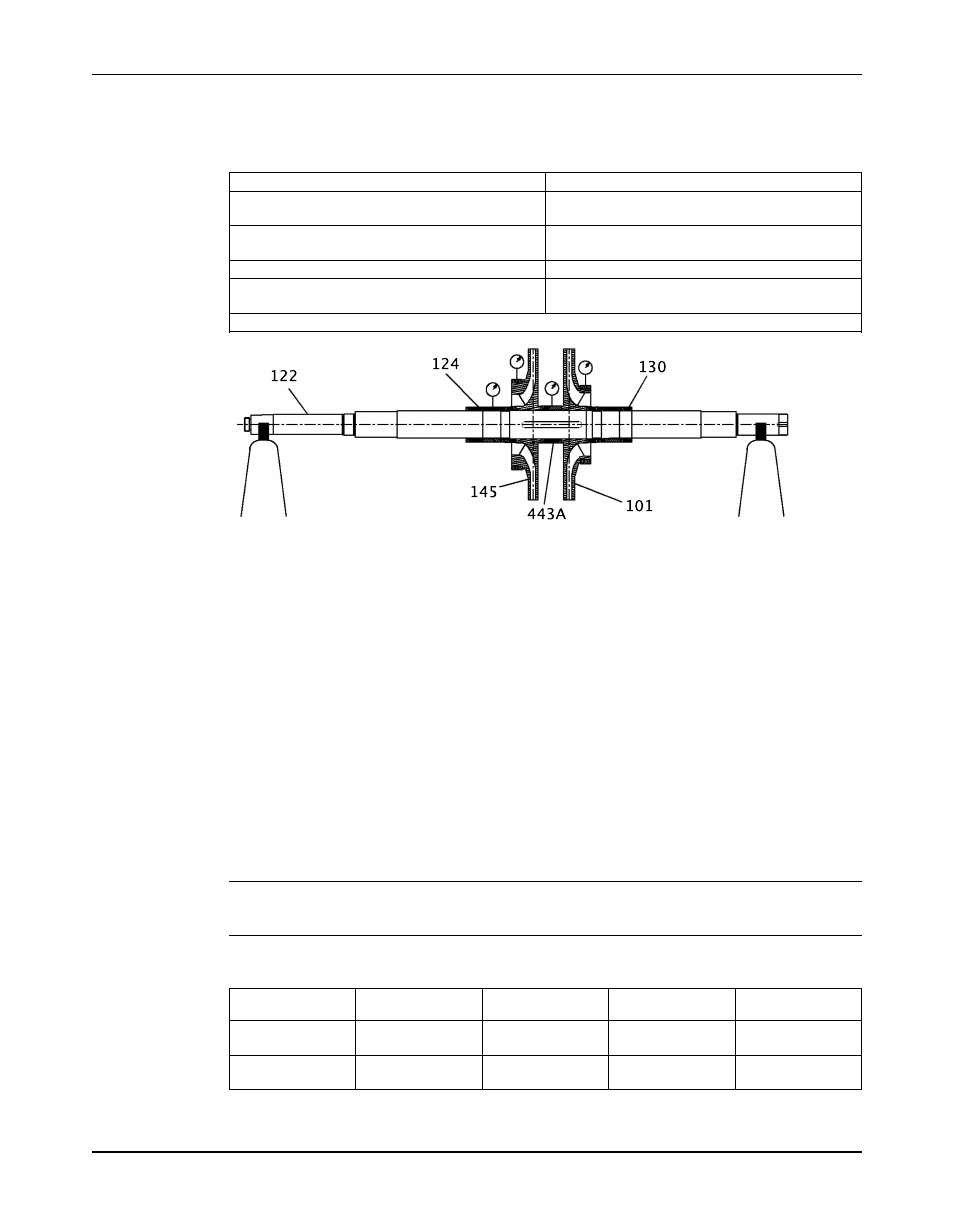

Figure 11: Fully assembled rotor

Bearings inspection

Condition of bearings

Do not reuse bearings. The condition of the bearings provides useful information on operating

conditions in the bearing frame.

Checklist

Perform these checks when you inspect the bearings:

• Inspect the bearings for contamination and damage.

• Note any lubricant condition and residue.

• Inspect the ball bearings to see if they are loose, rough, or noisy when you rotate them.

• Investigate any bearing damage to determine the cause. If the cause is not normal wear,

correct the issue before you return the pump to service.

Replacement bearings

Replacement bearings must be the same as, or equivalent to, those listed in this table.

NOTICE:

Thrust bearings must have machined bronze cages (retainers).

Table 3: Model 3640 ball bearing fits

Bearing numbers are based on SKF/MRC designations.

Frame group

Nameplate radial

Nameplate thrust

Bearing housing

Shaft turn

bearing

bearing

bore

S

6407

7407/BECBM

3.9379 (100.022)

1.3785 (35.013)

3.9370 (100.000)

1.3780 (35.002)

M

6309

7309/BECBM

3.9379 (100.022)

1.7722 (45.013)

3.9370 (100.000)

1.7717 (45.002)

Model 3640 Installation, Operation, and Maintenance Manual

69