Maintenance, Inspection, Operation – COOK Power-Plume User Manual

Page 3: Wheel-to-inlet clearance, Wheel / inlet overlap 1/2” wiring installation, Use of variable frequency drives, Wheel rotation, Lubrication - motor bearings, Motor services, Motor replacement

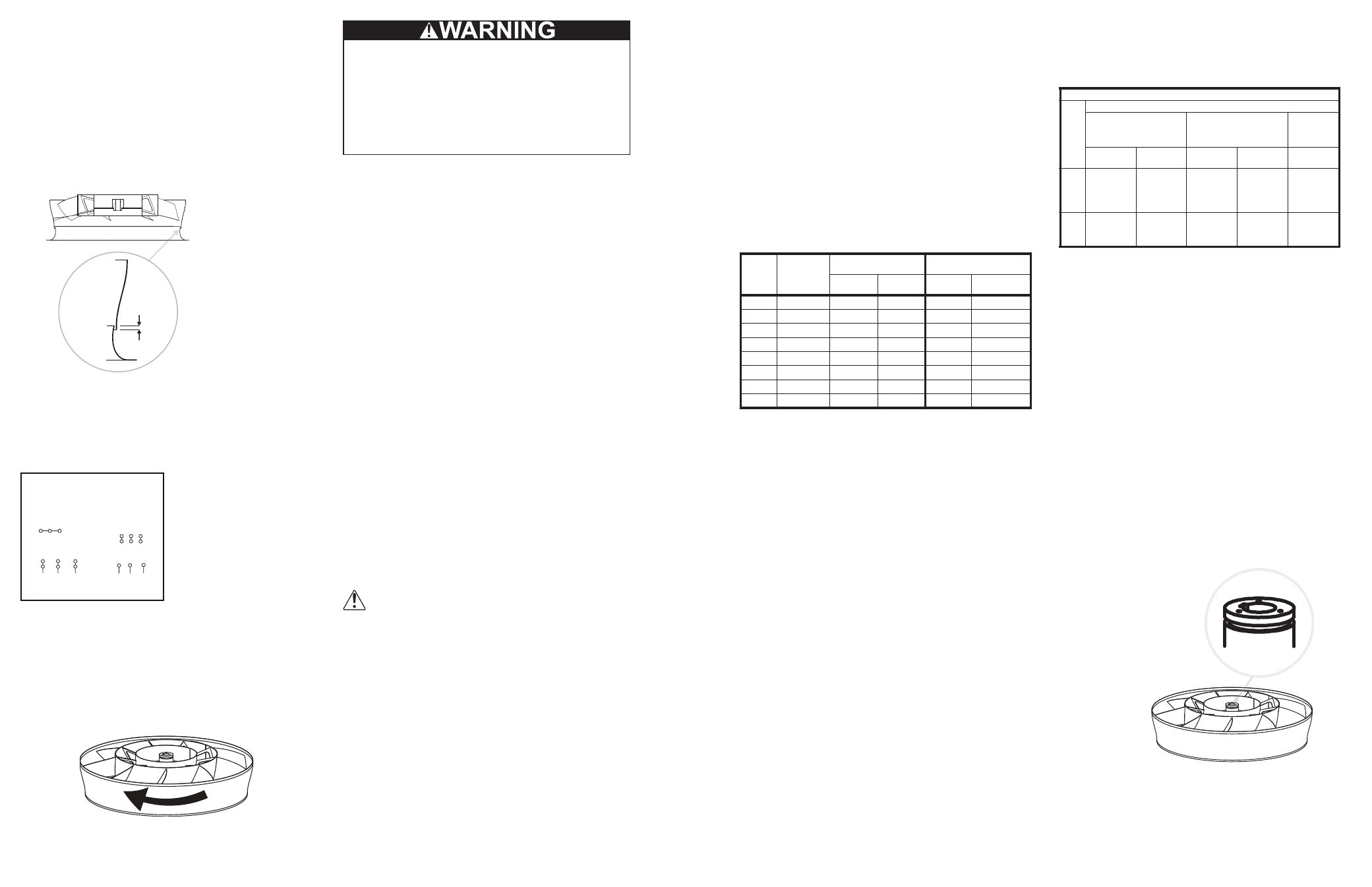

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to wheel/inlet

drawing below for correct overlap.

Adjust the overlap by loosening the wheel hub and

moving the wheel along the shaft to obtain the correct

value. Trim balance as necessary (.0785 in/sec max).

A uniform radial gap (space between the edge of the

cone and the edge of the inlet) is obtained by loosening

the inlet cone bolts and repositioning the inlet cone.

Wheel / inlet

overlap 1/2”

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor

nameplate.

* Leads for L

1

L

2

L

3

are prewired to

disconnect switch

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2 3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

*

Use of Variable Frequency Drives

The low-speed (12-pole) motor used on the Power-

Plume is not suitable for use with a Variable Frequency

Drive (VFD). Use of a VFD will potentially damage the

motor and void the motor warranty.

Wheel Rotation

Test the fan to ensure the rotation of the wheel is the

same as indicated by the arrow marked Rotation.

prevent potentially catastrophic damage.

Tight clearances between the rotor and stationary

members could “freeze over” during non-operating hours.

Therefore, the unit should always be inspected to ensure

the rotor is released and air passageways are open and

clear of all debris prior to any restart.

NOTICE! Although a certain amount of vibration

is inherent in operating fans, extreme vibration is

a serious problem that may cause structural and

mechanical failure.

Inspection

Inspection of the fan should be conducted at the first

30 minute, 8 hour and 24 hour intervals of satisfactory

operation. During the inspections, stop the fan and inspect

bolts, setscrews, and motor mounting bolts. Adjust and

tighten as necessary.

Recommended Torque for Setscrews Bolts ( in / lbs. )

Size

Key Hex

Across

Flats

Recommended

Torque

Hold Down Bolts

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2400

1/2”

1/4”

504

600

1” -8

3000

5/8”

5/16”

1104

1200

1 1/8”-7

4200

3/4”

3/8”

1440

1800

1 1/4”-7

6000

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating

conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated

air within the first month of operation. Fans exhausting

contaminated air (airborne abrasives) should be inspected

every three months.

Regular inspections are recommended for fans

exhausting non-contaminated air.

It is recommended the following inspection be

conducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel

and housing prevents imbalance and damage

Lubrication - Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below.

Motor bearings without provisions for relubrication will

operate up to 10 years under normal conditions with no

maintenance. In severe applications, high temperatures

or excessive contaminates, it is advisable to have the

maintenance department disassemble and lubricate the

bearings after 3 years of operation to prevent interruption

of service.

For motors with provisions for relubrication, follow

intervals of the table below.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with a

compatable grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

Relubrication Intervals

Service

Co

ndit

ion

s

NEMA Frame Size

Up to

and including

184T

213T-365T

404T

and larger

1800 RPM

and less

Over

1800 RPM

1800 RPM

and less

Over

1800 RPM

1800 RPM

and less

S

ta

n

d

a

rd

3 yrs.

6 months

2 yrs.

6 months

1 yr.

Severe

1 yr.

3 months

1 yr.

3 months

6 months

The above intervals should be reduced to half for

vertical shaft installations.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative

or your nearest authorized electric motor service

representative.

Motor Replacement

The motor can be removed using the following

sequence.

1. Disconnect the power to the Power-Plume®.

2. Disconnect the motor wires from the service switch

that is located on the motor housing.

3. Remove the top section of the fiberglass windband

4. Remove the cover plate from the wheel hub.

5. Loosen the set screws in the wheel and remove the

wheel from the motor shaft (see 3 steps below). The

wheel has a pre-machined shoulder on the hub for

the use of most 2 or 3 jaw mechanical pullers.

a Align center of the puller with center of the shaft.

b Ensure all setscrews in the hub, normally two,

are fully removed.

c Slowly remove the wheel from the shaft.

Pre-Machined

Shoulder

6. Remove the mounting bolts and motor lubrication

lines from the motor mounting plate.

7. Lift the motor using the supplied lifting lugs.

8. Remove the motor mounting bolts and motor

mounting plate.

To replace the motor reverse the steps used to remove.

Fire & Electrical Shock Hazard:

Do not allow the fan to run in the wrong direction. This

will overheat the motor and cause serious damage.

For 3-phase motors, if the fan is running in the wrong

direction, check the control switch. It is possible to

interchange two leads at this location so that the fan is

operating in the correct direction.

Final Installation Steps

1. Inspect fasteners and setscrews, particularly

fan mounting and bearing fasteners, and tighten

according to the recommended torque shown in the

table Recommended Torque for Setscrews/Bolts.

2. Inspect for correct voltage with voltmeter.

3. Ensure all accessories are installed.

Operation

Pre-Start Checks

1. Lock out all the primary and secondary power

sources.

2. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

3. Inspect motor wiring.

4. Ensure fan and ductwork are clean and free of

debris.

5. Inspect wheel-to-inlet clearance. The correct

wheel-to-inlet clearance is critical to proper fan

performance.

6. Close and secure all access doors.

7. Restore power to the fan.

Start Up

Turn the fan on. In variable speed units, set the fan to

its lowest speed and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for

squealing).

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. See Troubleshooting.

Winter Operation

When operating the Power-Plume in near or below

freezing weather there is always the potential for ice

buildup on any exposed surfaces, stationary or rotating.

Frequent inspection is very important for proper operation

of the unit. Under certain conditions severe ice buildup

can occur in a matter of minutes. These conditions are

not only produced by the weather but by the installation

as well. Only observation and experience will provide any

level of certainty for the safe and ice free operation of the

Power-Plume in any given location. If ice is discovered

during operation the unit should be shut down immediately

and the ice removed before operation is resumed.

A useful accessory for cold-climate operation is a

vibration cut-out switch. Should ice buildup begin, the

resulting vibration would be detected and the switch could

3

2