Operation, Maintenance – COOK ERV Evaporator Coil Supplement User Manual

Page 2

2

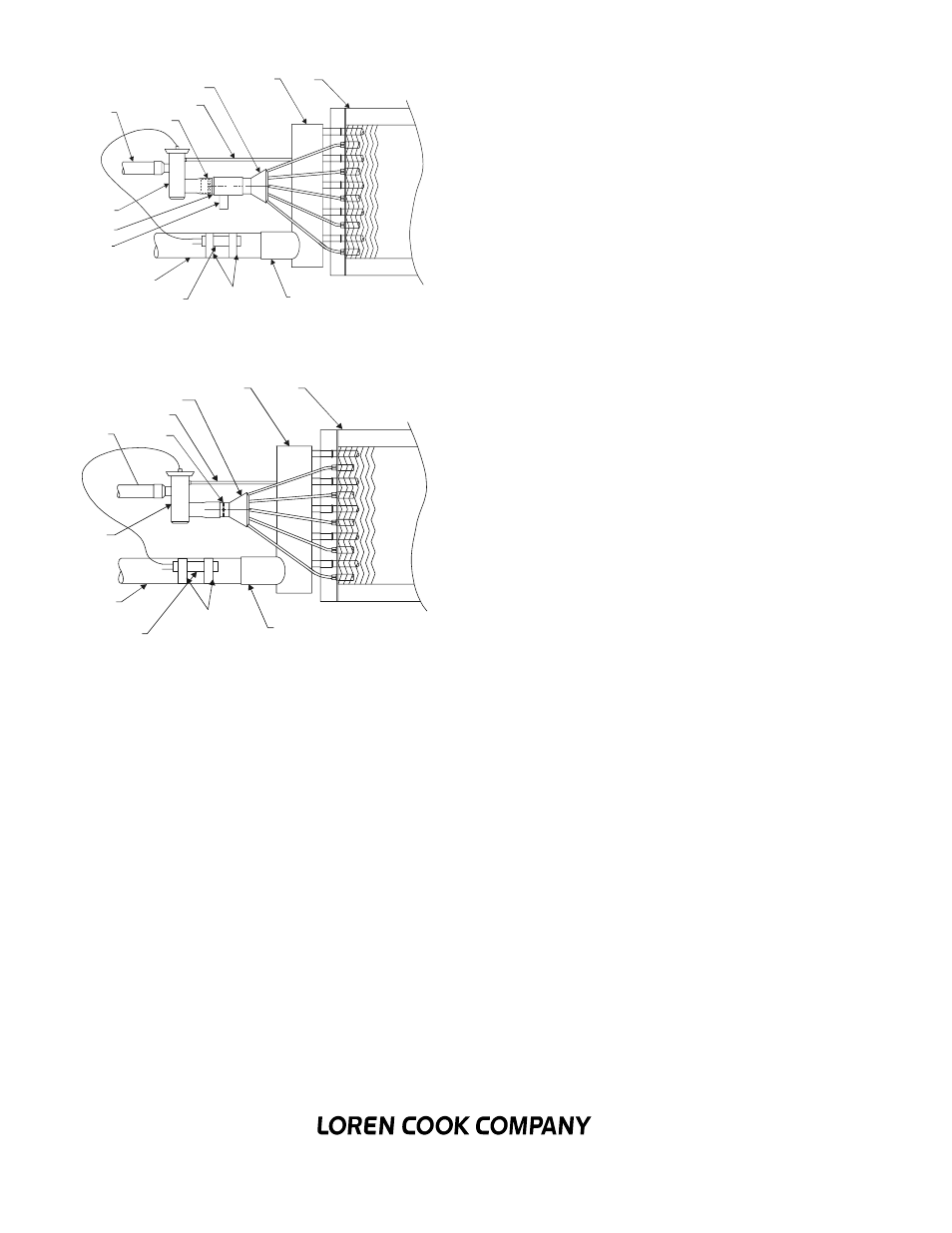

Suction Line

Expansion Valve

Remote Sensing Bulb

Straps

Suction Connection

Coil

Suction Header

Distributor

Equalizer Line

Nozzle

Liquid Line

12.

Refer to Figure 4 - Hot Gas Bypass Kit Installed and Fig-

ure 5 - General Diagram, for general piping.

Operation

1.

Proper air distribution is vital to coil performance. Air flow

anywhere on the coil face should not vary by more than 20%.

2.

Air velocities should be maintained between 200 and 550

feet per minute.

3.

The drain pan should be designed and installed such that

there is no standing water.

Maintenance

1.

Filters should be inspected on a regular basis and changed

as needed. Maintaining clean filters is a cost-effective way to help

maintain maximum coil performance and service life.

2.

Periodic inspection of the coil for signs of corrosion and for

leaks is recommended. Small leaks can be detected using a

Halide torch. Repair and replacement of the coil and the connect-

ing piping, valves, etc., should be performed as needed by a qual-

ified individual(s).

3.

Should the coil surface need cleaning, caution should be

exercised in selecting the cleaning solution as well as the cleaning

equipment. Improper selection can result in damage to the coil

and/or health hazards. Clean the coil from the leaving air-side so

that foreign material will be washed out of the coil rather than

pushed further in. Be sure to carefully read and follow the manu-

facturer’s recommendations before using any cleaning fluid.

4.

The use of filter-dryers in the system piping is recommended

along with a sight glass that has a moisture indicator. Replace the

filter dryer(s) as needed.

Note:

Refrigerant conversions are beyond the scope of this

manual and should only be performed by qualified parties.

Corporate Offices:

2015 E. Dale Street

Springfield, MO 65803 417.869.6474

lorencook.com

ERV Evaporator Coil IOM Supplement- December 2002

Remote Sensing Bulb

Suction Line

Liquid Line

Nozzle

Equalizer Line

Distributor

Suction Header

Coil

Expansion Valve

Hot Gas By-Pass

Hot Gas Side Port

Straps

Suction Connection

Figure 4 - Hot Gass Bypass Kit Installed

Figure 5 - General Diagram