Operation, Real time pressure, Motor output percentage – COOK Constant Pressure Control System User Manual

Page 2: Set point, Status, Hour meter, Electrical interferences hazard, Wiring diagram

The controller comes pre-programmed from the

factory. At initial power-up, the controller initiates and

the target pressure will be set at 0.00” w.g. and the

display will show the main screen as shown below.

Real Time Pressure

The actual real time pressure reading is displayed in

the field labeled RealT and is given in inches of water

gage.

Motor Output Percentage

The current motor output percentage is displayed

under the field labeled Motor%. This is the measure of

the motor speed that is currently being called for by the

controller. The value varies from 20 to 100 percent. The

motor will shut down when the value called for drops

below 20 percent.

Set Point

The current set point value is displayed in the field

labeled SetPt and is given in inches of water gage.

The set point can be changed using the third and fourth

buttons from the left edge of the controller. The button

with the symbol below it will increase the set point

value and the button with the symbol will decrease the

set point value.

Status

The display will also give the user feedback as to what

state the controller is operating.

• Normal:

If the pressure is within the acceptable range of the

set point and the motor speed is stabilized, the status

will be given as Normal.

• Max:

If the controller is calling for more fan output but the

motor is at the maximum rpm, the status will be given

as Max.

• Min:

If the controller is calling for less fan output but the

motor is at the minimum rpm, the status will be given

as Min.

Hour Meter

During normal operating mode, push the button with

the below it and the display will give a read out of the

number of hours that controller has been operating.

Connect the low voltage input wires from the EC motor

to the output connections for the control box per the

wiring diagram.

Electrical Interferences Hazard:

Low-voltage control wires and high-voltage power

wires must be installed in separate conduit from

control box to the EC motor.

Failure to follow these instructions could result in

malfunction or damage.

Wiring Diagram

SPECIAL DRAWING TITLE BLOCK INFO COMES FROM DRAWING i-Properties

SUMMARY/COMMENTS

Pressure Control Box

EC Motor

DS

by

Others

A

B

C

1 2 3

Control Signal - Red (0-10 VDC)

Common - White

Logic Control Power - Black (24 VAC)

Black (115 VAC - Hot)

White (115 VAC - Neutral)

Green (Ground)

Green (Ground)

White (115 VAC - Neutral)

Black (115 VAC - Hot)

Ground

115 VAC - Neutral

115 VAC - Hot

Hp FLA

1/4

3.8

1/2

6.3

3/4

9.5

1 AMP

Max

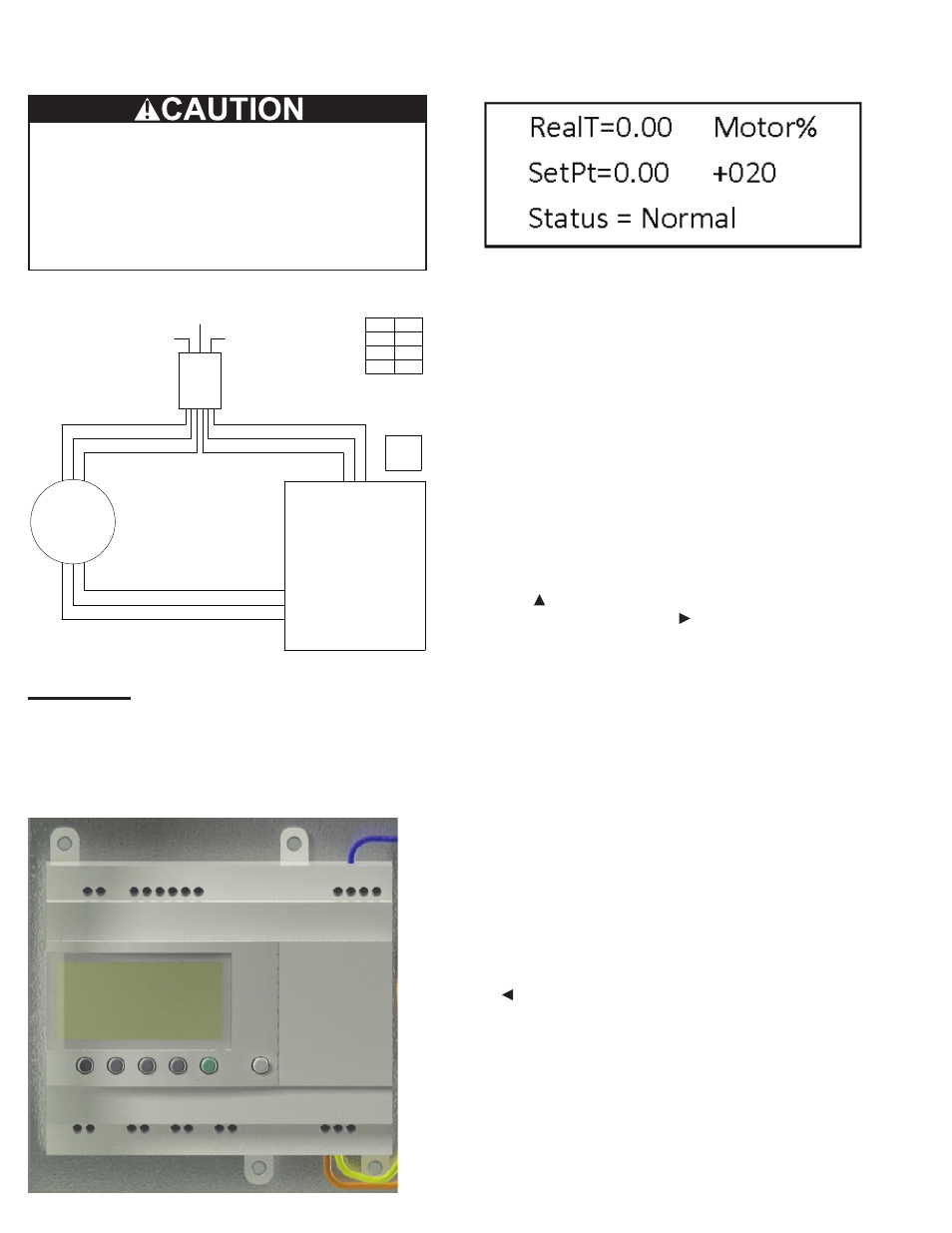

Operation

The controller is shown below. It has a LCD screen

that gives feedback as to the actual pressure reading,

pressure set point, motor operating percent, and status.

It also has six buttons that change the set point as well as

give access to other controller functions.

Figure 4 Note: Allow for ceiling thickness.

Suggested Installation: Unit with filter.

Constant Pressure Control System

For electronically commutated motors IOM - April 2012