Part, Troubleshooting, Cpl parts list - arrangement 3 – COOK CPL User Manual

Page 7

7

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at

the inlet.

•Improper wheel alignment.

Excessive Vibration and Noise

•Damaged or unbalanced wheel.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge or incorrect inlet or outlet conditions.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same

direction as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

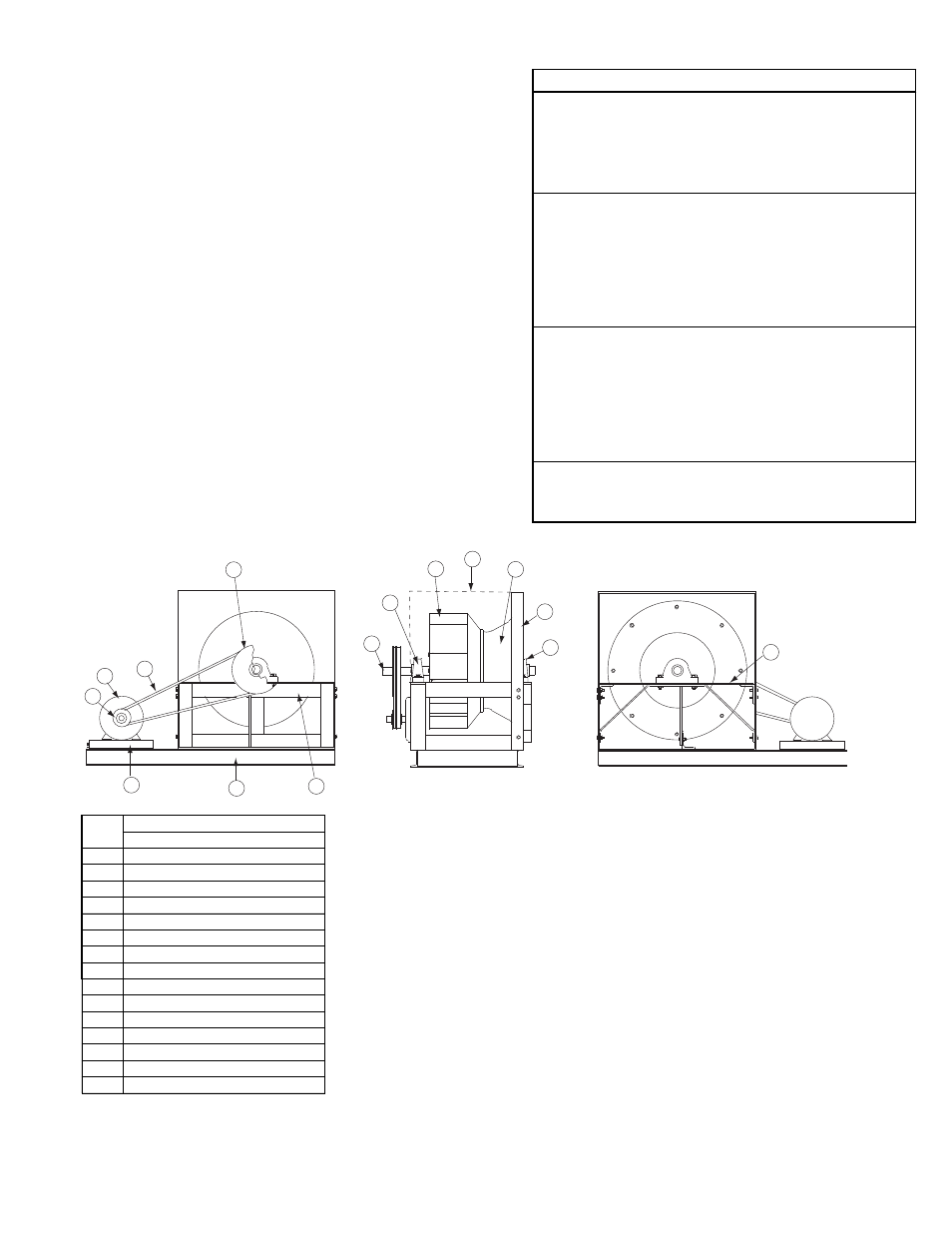

Part

No.

Description

Sizes 120 - 730

1

Motor Sheave

2

Motor

3

Belt Set

4

Fan Sheave

5

Shaft

6

Drive Side Bearing

7

Wheel

8

Safety Screen Enclosure (optional)

9

Inlet Cone

10

Inlet Panel

11

Inlet Side Bearing

12

Inlet Side Bearing Support

13

Drive Side Bearing Support

14

Isolation Base (Optional)

15

Motor Slide Base (Optional)

CPL Parts List - Arrangement 3

p. Repeat the process for opposite bearing.

q. Adjust the belt tension.

r. Test run and retighten all setscrews and bolts. Trim

balance as necessary (.0785 in/sec max.).

After 24 hours of operation, retighten the setscrews to

the appropriate torque. This assures full locking of the inner

race to the shaft. Make sure the socket key or driver is in

good condition with no rounded corners. The key should be

fully engaged in the setscrew and held squarely to prevent

rounding out of the setscrew socket when applying maxi-

mum torque.