A.O. Smith 400A User Manual

Page 13

3

2. Drill a pilot hole approximately 1/4" (6 mm) outside of the marked

circle. This pilot hole is used as a starting point for a saws-

all or sabre saw blade. Cut around the marked circle staying

approximately one quarter inch outside the line. (This will allow

the vent pipe to easily slide through the opening). The resulting

gap will be covered by the roof boot/flashing.

3. Suspend the pipe through center of hole using proper support.

4. Slide roof boot or equivalent flashing over pipe and secure roof

boot equivalent flashing to roof.

5. Seal around flashing.

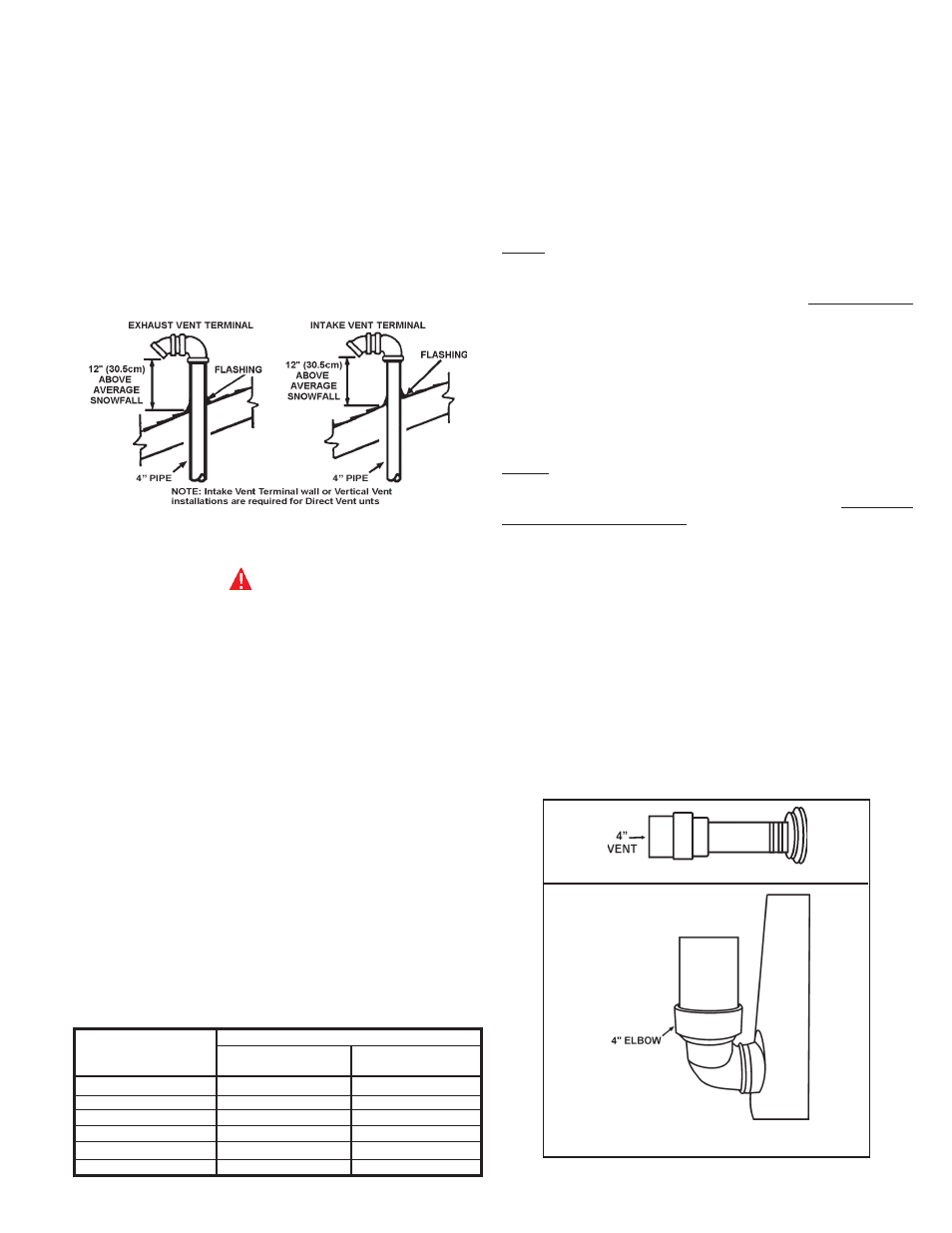

6. Terminate intake terminal and exhaust vent terminal facing down.

See Figure .

FIGURE 11.

INSTALLATION OF VENT SYSTEM

WARNING

THE OPTIONAL INTAKE VENTING ARRANGEMENT AND THE

EXHAUST VENTING ARRANGEMENT MUST BE INSTALLED TO

RUN DIRECTLY TO THE OUTDOORS AND NOT IN ANY WAY BE

CONNECTED TO ANOTHER VENTING SYSTEM (I.E. FURNACE,

DRYERS OR SPACE HEATERS). IT IS CRUCIAL THAT THE

VENTING ARRANGEMENT BE KEPT SEPARATE FROM OTHER

VENTING SYSTEMS. IF THIS WARNING IS IGNORED, AND THE

SYSTEM IS VENTED INCORRECTLY, IT MAY CAUSE IMPROPER

OPERATION, FIRE, EXPLOSION, OR ASPHYXIATION.

1. Plan the route of the vent system from the vent termination to the

planned location of the appliance. Layout the total vent system

to use the minimum of vent pipe and elbows possible.

2. This unit is certified for the use of 4-inch PVC pipe for venting.

The maximum length of 70-equivalent feet of 4-inch PVC pipe

may be used for the intake venting arrangement and a maximum

length of 70-equivalent feet of 4-inch PVC pipe may be used on

the exhaust venting arrangement. If the supply gas pressure

(dynamic) is set between 7" wc - 9" wc, the maximum allowed

length is 80 equivalent feet for both air intake and exhaust venting.

The maximum number of 90 degree elbows for the 4-inch venting

is six (6) in the intake and six (6) on the exhaust. A 90 degree

elbow is equal to five (5) equivalent feet of 4-inch pipe. One 90

degree elbow is equaled to two 45 degree elbows.

Table 2. VENT LENGTH TABLE

3. The unit is certified to a minimum amount of 4-inch pipe for

the exhaust venting arrangement of 15-equivalent feet. This is

the minimum amount of pipe required for the exhaust venting

arrangement. The intake venting arrangement is certified to use

a minimum of 0-equivalent feet of 4-inch PVC pipe.

IMPORTANT

When multiple units are direct vented through a wall (4-inch venting),

all intake vent terminals should be no lower than the highest exhaust

vent terminal.

NOTE: This unit can be vented using only PVC (Class 160, ASTM

D-2241 Schedule 40, ASTM D-1785 ; or Cellular Core Schedule

40 DWV, ASTM F-891) , Schedule 40 CPVC (ASTM F-411), or ABS

(ASTM D-2661) pipe. The fittings, other than the TERMINATIONS

should be equivalent to PVC-DWV fittings meeting ASTM D-2665

(Use CPVC fittings, ASTM F-438 for CPVC pipe and ABS fittings,

ASTM D-2661/3311 for ABS pipe. If CPVC or ABS pipe and fittings

are used, then the proper cement must be used for all joints, including

joining the pipe to the Termination (PVC Material). PVC Materials

should use ASTM D-2564 Grade Cement; CPVC Materials should

use ASTM F-493 Grade Cement and ; ABS Materials should use

ASTM D-2235 Grade Cement.

NOTE: for Water Heaters in locations with high ambient

temperatures (above 100°F or 38°C) and/or insufficient dilution air,

it is recommended that CPVC or ABS pipe and fittings (MUST USE

SUPPLIED VENT TERMINAL) be used.

5. It is important that condensate not be allowed to buildup in the

exhaust vent pipe. To prevent this from happening the pipe should

be installed with a slight, 1/8 inch (3mm) per 5 feet (152 cm) of

pipe maximum downward slope.

6. The vent system should be supported every 5 feet (152 cm) of vertical

run and every 3 feet (91cm) of horizontal run of vent pipe length.

NOTE: Stress levels in the pipe and fittings can be significantly

increased by improper installation. If rigid pipe clamps are used to

hold the pipe in place, or if the pipe cannot move freely through a

wall penetration, the pipe may be directly stressed, or high thermal

stresses may be formed when the pipe heats up and expands. Install

accordingly to minimize such stresses.

FIGURE 12.

Number

4" PVC

of 90°

Maximum

Maximum

Elbows

Feet. of Pipe

Meters of Pipe

ONE (1)

65'

19.7 m

TWO (2)

60'

18.2 m

THREE (3)

55'

16.7 m

FOUR (4)

50'

15.2 m

FIVE (5)

45'

13.6 m

SIX (6)

40'

12.1 m

OUTLET VIEW

INLET VIEW